Real sampling, Narrow space measuring typical applications – Atec Mitutoyo-SJ-410 User Manual

Page 5

5

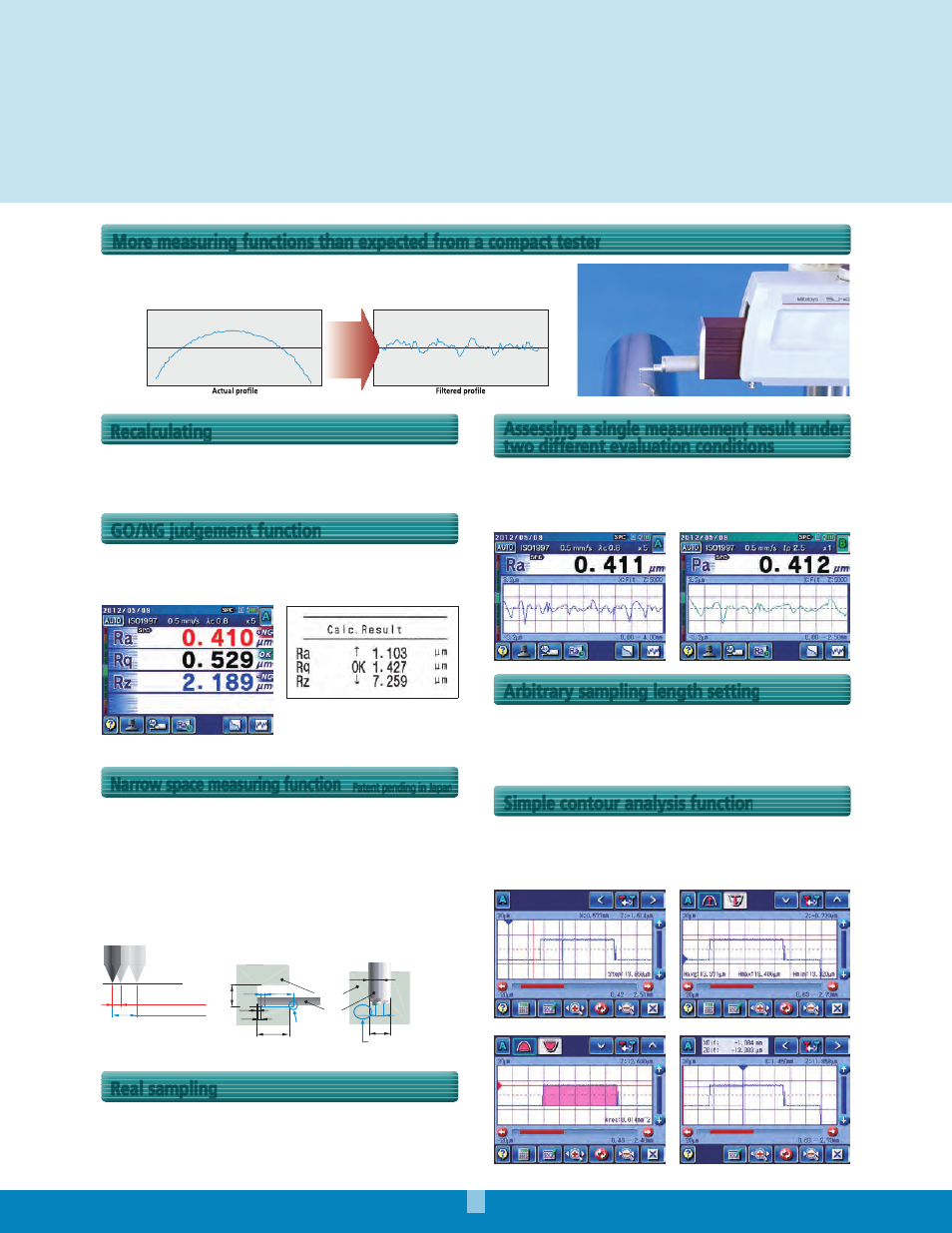

Usually, a spherical or cylindrical surface (R-surface) cannot be evaluated, but, by removing

the radius with a filter, R-surface data is processed as if taken from a flat surface.

Step

Dimensions

Step volume

Coordinate difference

More measuring functions than expected from a compact tester

R-Surface

compensation

R-Surface

compensation

Previously measured data can be recalculated for use in other

evaluations by changing the current standard, assessed profile and

roughness parameters.

A single measurement enables simultaneous analysis under two

different evaluation conditions. A single measurement allows calculation

of parameters and analysis of assessed profiles without the need for

recalculation after saving data, contributing to higher work efficiency.

Point group data collected for surface roughness evaluation is used

to perform simplified contour analysis (step, step height, area and

coordinate variation). It assesses minute forms that cannot be assessed

by a contour measurer.

This function allows a sampling length to be arbitrarily set in 0.01mm

increments (SJ-411: 0.1mm to 25mm, SJ-412: 0.1mm to 50mm).

It also allows the SJ-410 series to make both narrow and wide range

measurements.

The “OK” symbol means the measurement

is within the limits set; “NG” means it is not,

in which case an arrow points to either the

upper or lower limit in the printout.

An “OK/NG” judgment symbol is displayed when limits are set for

the roughness parameter. In case of “NG,” the calculated result

is highlighted. The calculated result can also be printed out.

Surface roughness measurement requires a run-up distance before

starting the measurement (or retrieving data). When the SJ-410

Series measures, its run-up distance is normally set to 0.5mm. This

distance, however, can be shortened to 0.15mm using the narrow

part measurement function (starting from the origin point of the drive

unit). The function extends the possibility of measurement of narrow

locations such as grooves in piston ring / O-ring mounts.

This function samples stylus displacement for a specified time

without engaging detector traverse, which enables use as a

simplified vibration meter or displacement gage incorporated in

another system.

Recalculating

Assessing a single measurement result under

two different evaluation conditions

Simple contour analysis function

Arbitrary sampling length setting

GO/NG judgement function

Narrow space measuring function

Patent pending in Japan

Real sampling

3.5

0.5

0.5

2.5

0.1

Example: surface roughness measuring

of piston-ring groove

Example: surface roughness measuring

of mounting groove for O-ring

Overruns surface

using 0.5mm run-up

Run-up of 0.5mm is not

enough for performing

the measurement

Evaluation length

λ

c=2.5mm

1 sampling length

Evaluation length

λ

c=0.8mm

1 sampling length

2.5

ø1.2

1.3

Stylus

Workpiece

Normal run up: 0.5mm

Run up for narrow parts

: 0.15mm

1.

8

The run-up distance can

be shortened to 0.15mm

by measuring from the

origin point.

•

Narrow space measuring

Typical applications