Cla-Val 750-60 User Manual

Page 6

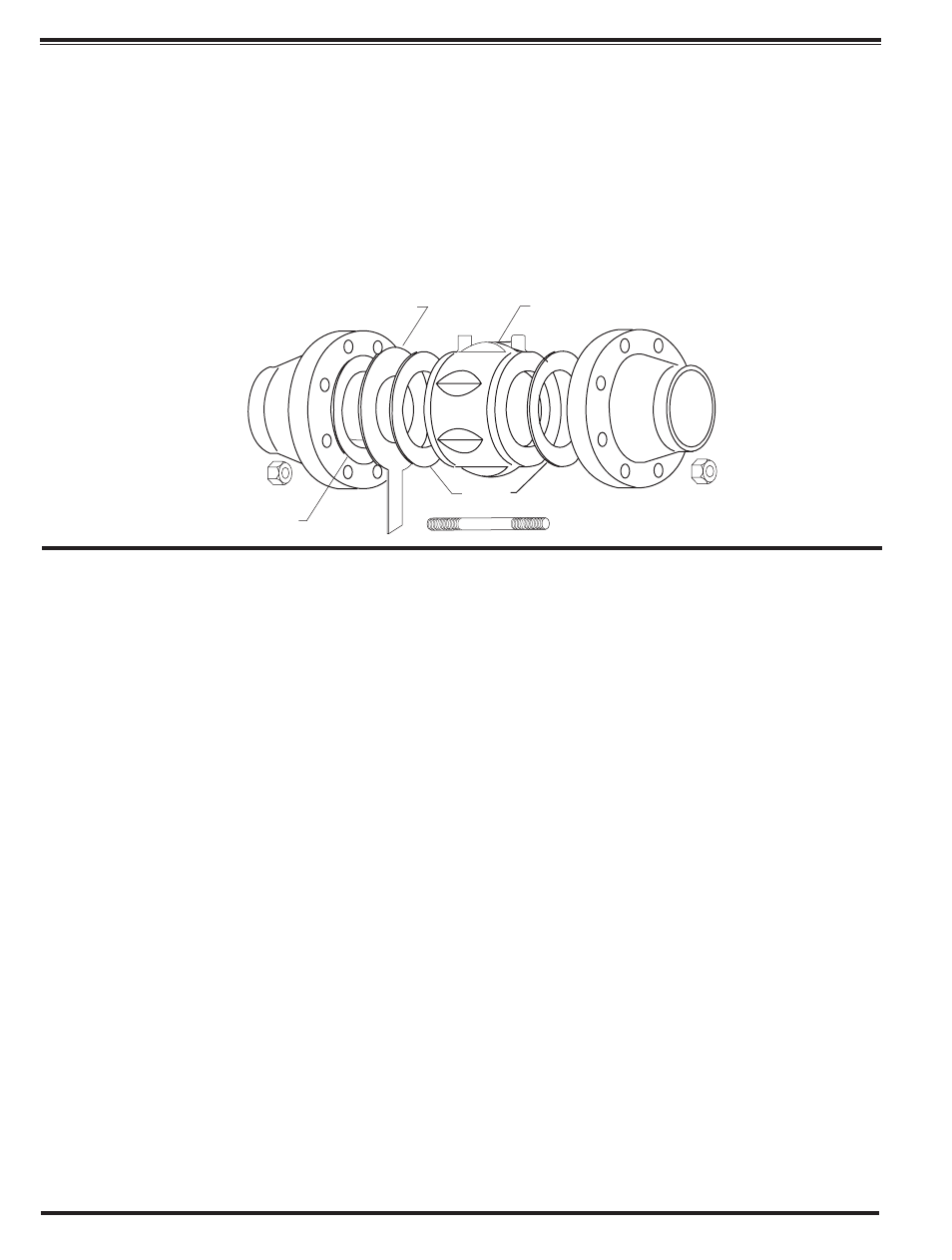

The Model 100-42 valve in 6" through

12" sizes are constructed with separa-

ble "slip-on" style flanges. Furnished

standard in either class 150 or 300

raised face type, the flanges are

removable and interchangeable. The

class 150 flange may be bolted up to

class 125 pipeline flanges and the

class 300 flange may be mated

against a class 250 flange.

Locate pilot system port connections

at the top of valve in pipeline to allow

easy air venting. A line size strainer is

recommended, mounted on the valve

inlet.

The valve should be given a visual inspec-

tion before installation to be sure no foreign

materials have collected inside the valve

during shipment or storage.

Pipelines should be flushed out before the

valve is installed in the system. New sys-

tems, especially, should be cleaned as con-

taminates such as welding beads, scale,

rocks, etc. are commonly contained within

the pipeline.

The valve should be installed in a location

allowing sufficient working space around

the valve to provide easy access for main-

tenance and removal for servicing.

For 2", 3", and 4" sizes only. Insert the lower

half pattern of stud bolts through the bolt

holes of the upstream and downstream

pipeline flanges.

For 2" & 3" valves only. The 125 and 150

series flanges use a different number of

bolts than the 250 and 300 series flanges.

Hence, the wafer valve body configuration

is inherently self centering regardless of the

flange used.

Install the valve between the flanges being

sure to include the appropriate flange gas-

kets between each end of the valve and the

mating pipe flange.

Note: The valve must be installed with the

flow arrow on side of body pointing to the

downstream piping section. Cla-Val 700

Series valves may be installed in any posi-

tion in either vertical or horizontal installa-

tions without any effect on valve operation.

Insert the remaining stud bolts and nuts and

tighten evenly using a diagonal cross-over

type pattern.

For the 4'' valve, ANSI pipe flanges use an

8 bolt pattern regardless of pressure rat-

ings, although the 250 and 300 series use

larger bolts on a larger bolt circle. The 4"

valve can be centered in the larger 250 and

300 class flanges by rotating the valve body

into full radial contact with the bolt studs

prior to tightening.

INSTALLATION

PROCEDURE

2.

3.

4.

4a.

6.

7.

1.

Gasket

Gasket

Recommended Strainer

Model 100-42 Roll Seal Valve

The Cla-Val Model 100-42 Roll Seal

valve in 2", 3", and 4" sizes are

designed to mount between standard

pipe flanges (ANSI 125, 150, 250, and

300 series) as a wafer type valve. The

outer portion of the valve body is con-

structed with fluted (recessed) sec-

tions to provide clearance for the class

125 and 150 flange bolt pattern while

the basic outside diameter of the body

centers within the class 250 and 300

flange bolt pattern.

If an inline basket type strainer is to be

included in the installation, insert the strain-

er into the upstream pipe, making sure a

gasket is placed between the strainer and

the upstream flange.

4b.

5.