Cla - val – Cla-Val 750-60 User Manual

Page 16

Install the range spring (Item 19) onto the

upper diaphragm plate and install the

spring pad (Item 16) onto the spring.

Set the spring housing (Item 20) onto the

diaphragm and install the eight body

screws (Item 10). Tighten the body screws

uniformly using a diagonal pattern to pre-

vent uneven loading on the diaphragm.

Install the adjustment screw assembly

(Item 14), including lock nut (Item15) and

adjustment cap (Item 11) on the spring

housing.

Remove the adjustment cap (Item 11).

Loosen the adjustment screw lock nut

(Item 15).

Turn the adjustment screw (Item 14) to

obtain the desired controlled pressure set-

ting. To increase the pressure setting, turn

the adjustment screw clockwise. To

decrease the pressure setting, turn the

adjustment screw counterclockwise.

Tighten the adjustment screw lock nut and

replace the adjustment cap.

Thoroughly clean all parts prior to reassem-

bly. It is recommended that a light film of

grease or oil be applied to all "O" rings to

ease assembly into body. It is also recom-

mended that a heavy bodied grease be

applied to the ball tip of the adjustment

screw (Item 14) before assembly into the

spring housing.

Insert the seat and guide bushing, with "O"

rings in place, into the pilot body (Item 7).

Install the retaining ring (Item 8) into the

groove.

Place the upper diaphragm plate (Item 5),

the diaphragm (Item 3) and the lower

diaphragm plate (Item 6) onto the cap screw

(Item 9). Insert the cap screw into the

plunger (Item 2) and tighten. Be very careful

not to damage the plunger surface during

this operation. Wrench flats are provided on

the plunger to hold the part while tightening

the cap screw.

Slide the plunger into the guide bushing and

rotate the diaphragm to line up the clear-

ance holes in the diaphragm with the

tapped holes in the body.

Remove the adjustment cap (Item 11) and

the adjustment screw (Item 14) to fully

relieve compression of the range spring.

Remove the eight body screws (Item 10)

and lift off the spring housing (Item 20).

Remove the range spring (Item 19) and the

spring pad (Item 16).

Remove the diaphragm (Item 3) and

attached parts from the body.

Inspect the diaphragm for wear or damage

and inspect the plunger (Item 2) for signs of

erosion or damage, particularly in the area

of the seating surface.

If any part shows damage, take the assem-

bly apart and replace the damaged compo-

nent. Disassemble by removing the cap

screw (Item 9) from the plunger. Be very

careful not to damage the plunger surface

during this operation. Wrench flats are pro-

vided on the plunger to hold the part while

removing the cap screw.

Remove the retaining ring (Item 8).

Remove the guide bushing (Item 4) and the

seat (Item 1) from the body. An easy

method of removal is to insert the plunger

through the outer port of the body and push

against the back surface of the seat.

Inspect the ''O" rings (Item 12 and 13 and

the seat (Item 1) for damage. Pay particular

attention to the sealing edge on the seat

and replace any parts showing damage.

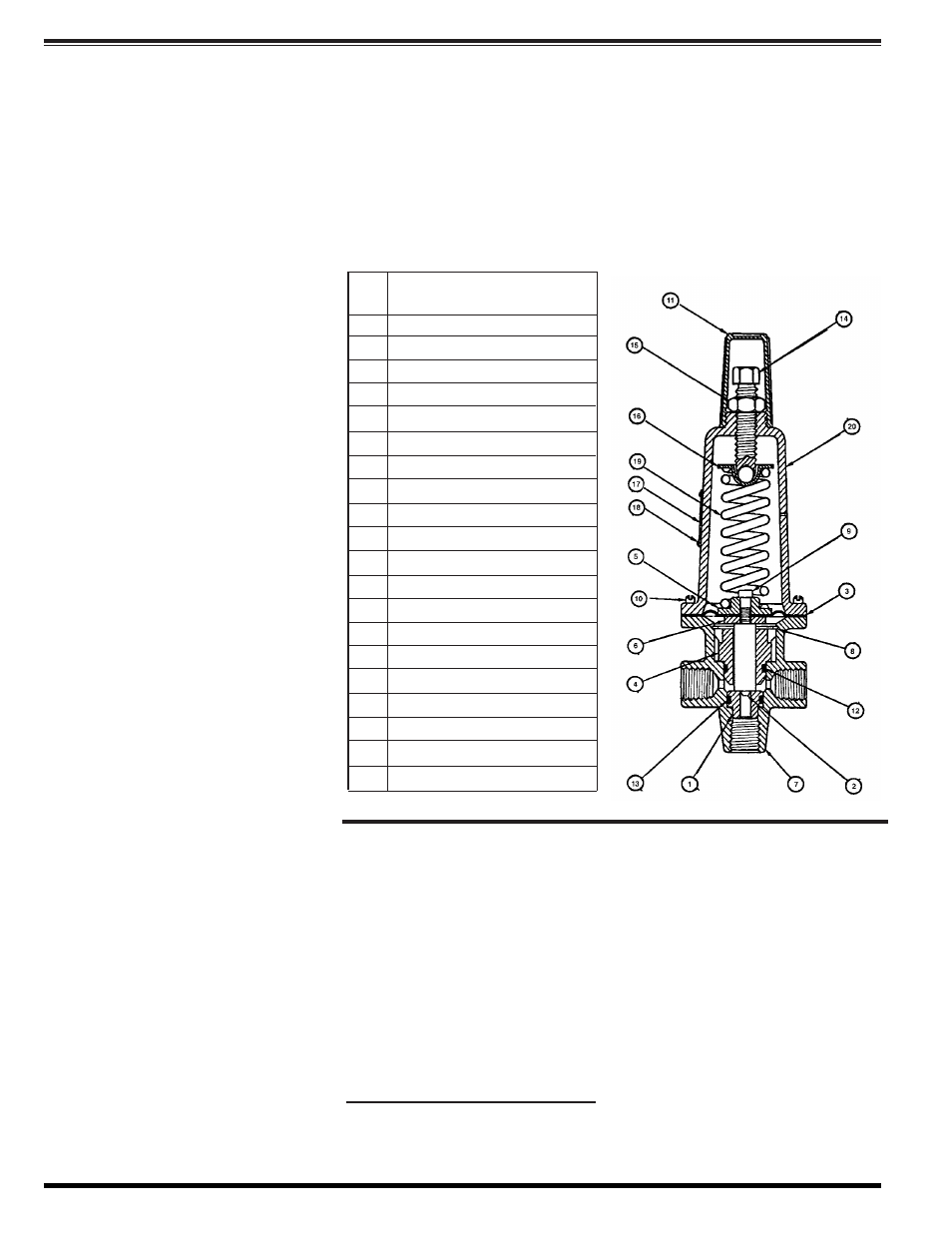

The procedure outlined below should be fol-

lowed when servicing the model RCBP

Back Pressure Control and Relief Pilot. Item

numbers, appearing with part names, are

keyed to the cross sectional parts list draw-

ing.

Disassembly

Pressure Adjustment

Reassembly

Item

No.

Description

1*

Seat

2

Plunger

3*

Diaphragm

4

Guide Bushing

5

Upper Diaphragm Plate

6

Lower Diaphragm Plate

7

Body

8

Retaining Ring

9

Cap Screw

10

Body Screw

11

Adjustment Cap

12*

"O" Ring

13*

"O" Ring

14

Adjustment Screw Assembly

15

Lock Nut

16

Spring Pad

17

Nameplate

18

Drive Screw

19

Range Spring

20

Spring Housing

* Recommended Spare Part

Specifications

When Ordering, Please Specify

1. Adjustment Range Desired

2. Materials Desired

Maintenance

Size

3/8" NPT Threaded

Adjustment Ranges

Temperature Range

Water: 180˚F Max.

psi: 10-90 (Silver)

Materials

25-150 (Red)

Body & Cover:

Cast Bronze ASTM B-62

50-300 (Blue)

Trim:

Brass & Stainless Steel 303

100-500 (Black)

Rubber:

Buna-N

®

(Fabric Reinforced)

Optional Materials

Bronze/Stainless Steel 316

Mounting Positions:

Stainless Steel 316

Multi-poise

Acetal Plastic

(operates in any position)

Viton & EPDM Rubber

.

Weight: 4 lbs

Pressure Rating

720 psi Max.

(All materials)

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

7.

8.

5.

6.

7.

1.

2.

3.

4.

CLA

-

VAL

© 2004

Cla-Val Printed in USA Specifications subject to change without notice.

P.O. Box 1325

•

Newport Beach, CA 92659-0325

•

Phone: 949-722-4800

•

Fax: 949-548-5441

•

E-mail: [email protected]

•

Website cla-val.com

N-RCBP (R-7/04)