Rcbp, Back pressure control and relief pilot, Model installation / operation / maintenance – Cla-Val 750-60 User Manual

Page 15

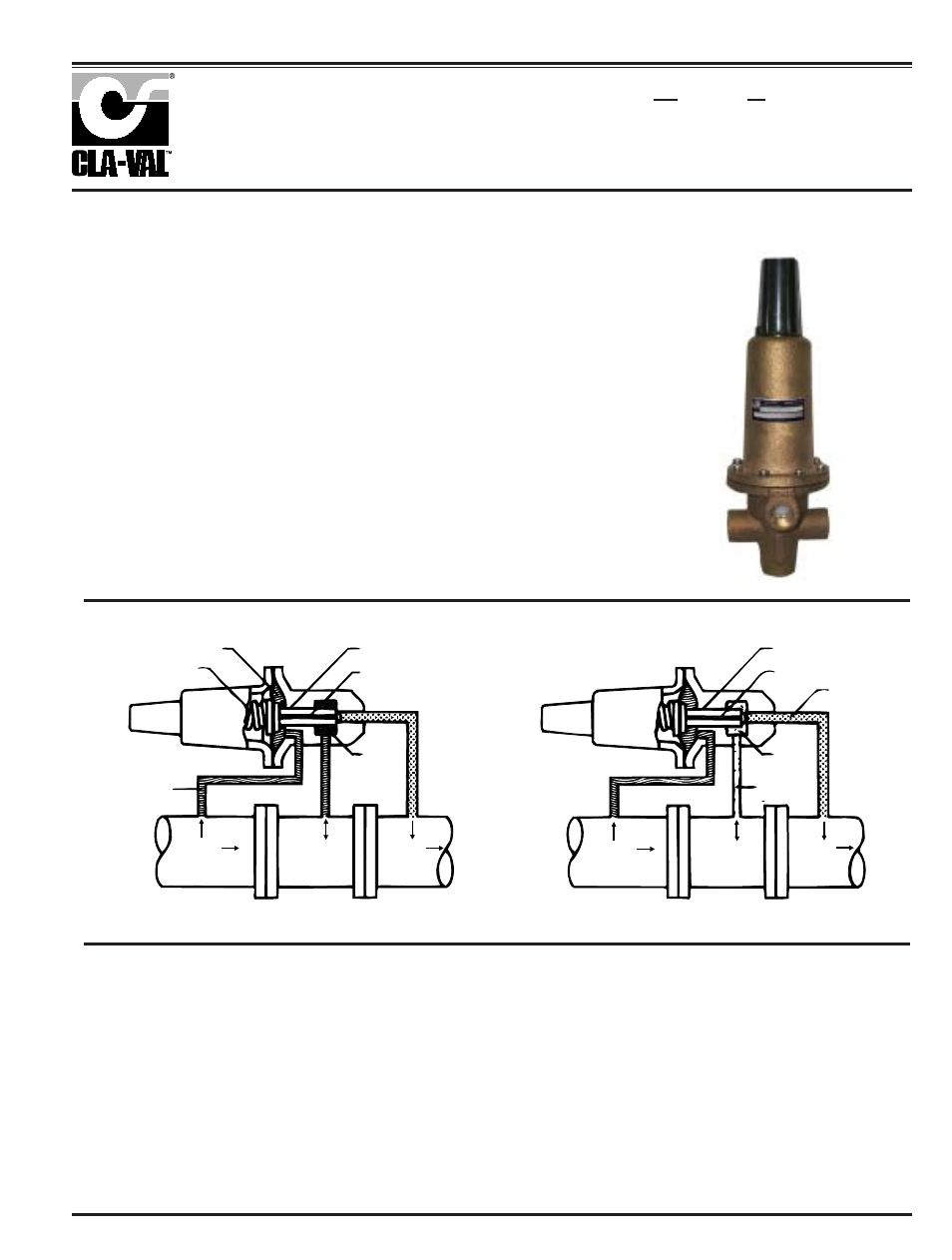

Plunger

Plunger

Restrictor

Restrictor

Diaphragm

Chamber

Loading

Pressure

Chamber

Loading

Pressure

Chamber

Loading

Pressure

Line

Supply &

Sense Line

OUTLET

OUTLET

INLET

INLET

MAIN VALVE

MAIN VALVE

Discharge

Line

Pressure Spring

RCBP

Back Pressure Control and Relief Pilot

The model RCBP pilot is used with Cla-

Val control valves to form a control unit to

function in either back pressure regulation

or pressure relief service.

Back Pressure Regulation Service

Accurately maintains upstream pressure

regardless of flow demand or downstream

pressure conditions.

Pressure Relief Service

Provides protection against excessive

main line system pressure.

Figures A and B schematically depict the

RCBP connected to a hydraulically oper-

ated valve.

Upstream pressure is supplied to the

diaphragm chamber. From here it is trans-

mitted to the loading pressure chamber

through the restrictor (formed by an axial

groove along the plunger guide bore).

When the upstream pressure is less than

Installation

The model RCBP pilot has one inlet port

(marked "sense"), two loading ports

(marked "loading") and one outlet port. A

flow arrow is stamped on the side of the

pilot body, near the outlet port, indicating

flow direction through the pilot. The sec-

ond loading port is an auxiliary port and

may be used for mounting of a pressure

gauge.

The pilot may be mounted in any desired

position. When installing the model

RCBP as a pilot control on a main valve,

connect the pilot as follows:

Connect one of the "loading" pressure

taps on the model RCBP to the "loading"

pressure tap on the main valve body.

Plug the second "loading" pres-sure tap

on the pilot if it is not to be used.

Connect a line from the "sense" port of

the pilot to the "inlet" port tap on the

main valve body or to a pressure tap con-

nection in the upstream system as

desired.

Connect a line from the "outlet" port of

the pilot to the "outlet" port tap on the

main valve body.

All line connections should be a mini-

mum of 3/8" pipe or tubing size. If the

"sense" line connection is made to a

pressure tap location further than two

feet from the valve, the connecting line

should be stepped up at least one size.

It is recommended that a small strainer

be added in the sense line to the pilot to

prevent clogging.

the setting established by the pressure

spring, the plunger is in the closed position

as shown in Figure A, thus full upstream

pressure is provided to the control chamber

of the main valve. Since the control chamber

and upstream pressures are equal, the main

valve remains in the closed position. When a

rising upstream pressure exceeds the pres-

sure spring setting, the plunger is shifted off

the seat towards the open position shown in

Figure B. Flow is then established through

the pilot circuit and exhausted through the

discharge port into the downstream system.

As a result of pilot circuit flow, a pressure

drop is developed across the restrictor.

Hence, the pressure supplied to the control

chamber is reduced permitting the main

valve to open and maintain a steady

upstream pressure.

Principle of Operation

Figure A

Figure B

1.

2.

3.

4.

5.

MODEL

INSTALLATION / OPERATION / MAINTENANCE