Hytrol valve, Model installation / operation / maintenance – Cla-Val 49-01/649-01 Technical Manual User Manual

Page 7

Description

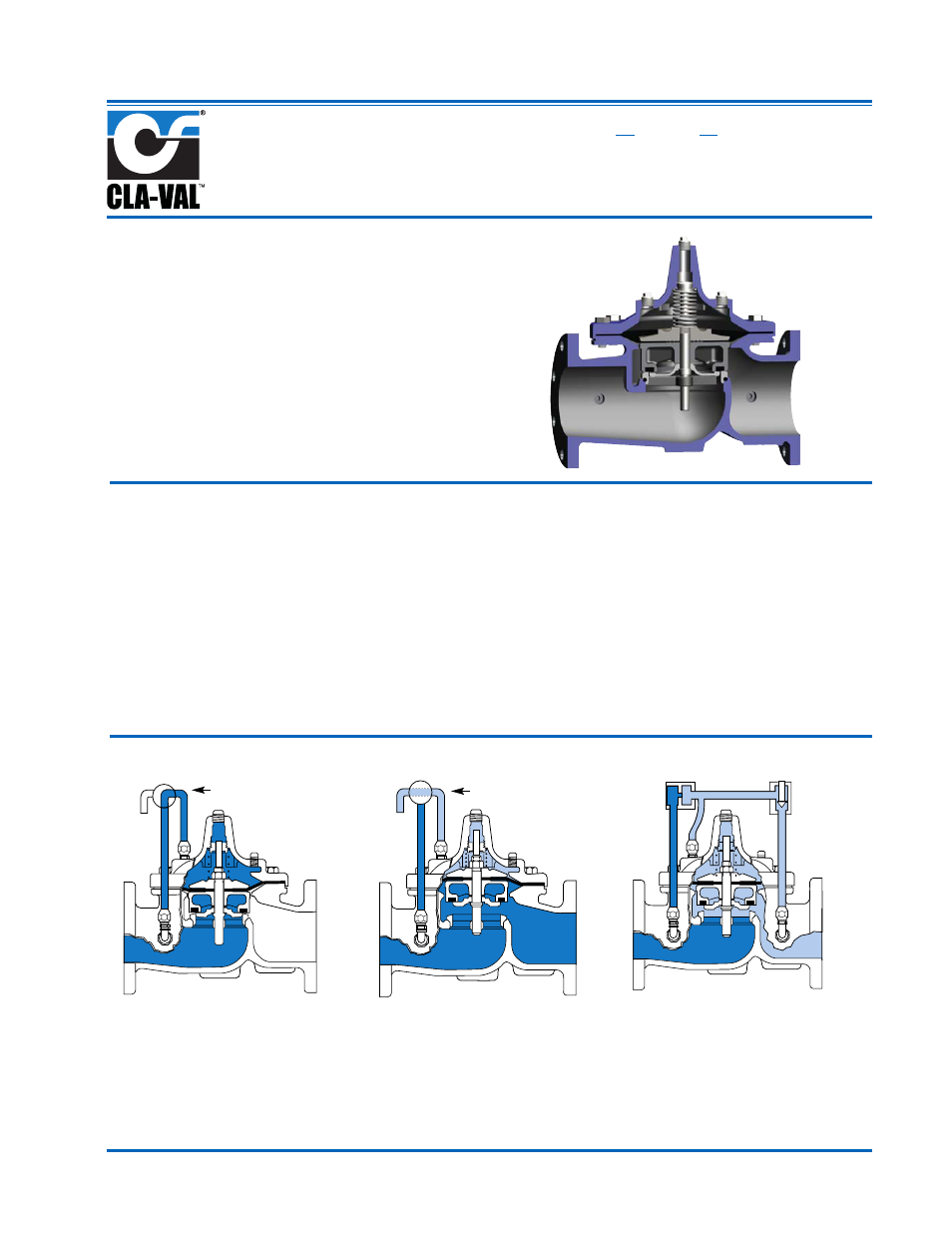

The CIa-VaI Model 100-01 Hytrol Valve is a main valve for

CIa-VaI Automatic Control Valves. It is a hydraulically operated,

diaphragm-actuated, globe or angle pattern valve.

This valve consists of three major components; body, diaphragm

assembly, and cover. The diaphragm assembly is the only

moving part. The diaphragm assembly uses a diaphragm of nylon

fabric bonded with synthetic rubber. A synthetic rubber disc,

contained on three and one half sides by a disc retainer and disc

guide, forms a seal with the valve seat when pressure is applied

above the diaphragm. The diaphragm assembly forms a sealed

chamber in the upper portion of the valve, separating operating

pressure from line pressure.

Installation

1. Before valve is installed, pipe lines should be flushed of all

chips, scale and foreign matter.

2. It is recommended that either gate or block valves be

installed on both ends of the 100-01 Hytrol Valve to facilitate

isoIating the valve for preventive maintenance and repairs.

3. Place the valve in the line with flow through the valve in the

direction indicated on the inlet nameplate. (See “Flow Direction”

Section)

4. Allow sufficient room around valve to make adjustments and

for disassembly.

5. CIa-VaI 100-01 Hytrol Valves operate with maximum efficiency

when mounted in horizontal piping with the cover UP, however,

other positions are acceptable. Due to size and weight of the

cover and internal components of 8 inch and larger valves,

installation with the cover UP is advisable. This makes internal

parts readily accessible for periodic inspection.

6. Caution must be taken in the installation of this valve to insure

that galvanic and/or electrolytic action does not take place. The

proper use of dielectric fittings and gaskets are required in all

systems using dissimilar metals.

7. If a pilot control system is installed on the 100-01 Hytrol Valve,

use care to prevent damage. If it is necessary to remove fittings

or components, be sure they are kept clean and replaced

exactly as they were.

8. After the valve is installed and the system is first pressurized,

vent air from the cover chamber and pilot system tubing by

loosening fittings at all high points.

Tight Closing Operation

When pressure from the valve inlet (or

an equivalent independent operating

pressure) is applied to the diaphragm

chamber the valve closes drip-tight.

Full Open Operation

When pressure in diaphragm chamber

is relieved to a zone of lower pressure

(usually atmosphere) the line pressure

(5 psi Min.) at the valve inlet opens the

valve.

Modulating Action

Valve modulates when diaphragm pres-

sure is held at an intermediate point

between inlet and discharge pressure.

With the use of a Cla-Val. "modulating

control," which reacts to line pressure

changes, the pressure above the

diaphragm is varied, allowing the valve

to throttle and compensate for the

change.

Principles of Operation

Three Way

Pilot Control

Three Way

Pilot Control

Restriction

Modulating

Control

100-01

Hytrol Valve

MODEL

INSTALLATION / OPERATION / MAINTENANCE