Pressure reducing control, Cla-val, Remote sensing type – Cla-Val 49-01/649-01 Technical Manual User Manual

Page 18: Model installation / operation / maintenance

DESCRIPTION

The CRA Pressure Reducing Control automatically reduces a higher inlet

pressure to a lower outlet pressure. It is a direct acting, spring loaded,

diaphragm type valve that operates hydraulically or pneumatically and is

designed to sense pressure from a remote point. It may be used as a self-

contained valve or as a pilot control for a Cla-Val Co. main valve. It will

hold a constant downstream pressure at the remote sensing point within

very close pressure limits.

OPERATION

The CRA Pressure Reducing Control is normally held open by the force

of the compression spring above the diaphragm; delivery pressure acts on

the underside of the diaphragm. Flow through the valve responds to

changes in pressure at the the sensing point.

INSTALLATION

The CRA Pressure Reducing Control may be installed in any position.

There is one inlet port and two outlets, for either straight or angle instal-

lation. The second outlet port can be used for a gauge connection. A flow

arrow is marked on the body casting.

ADJUSTMENT PROCEDURE

The CRA Pressure Reducing Control can be adjusted to provide a deliv-

ery pressure range as specified on the nameplate.

Pressure adjustment is made by turning the adjustment screw to vary the

spring pressure on the diaphragm. The greater the compression on the

spring the higher the pressure setting.

1. Turn the adjustment screw in (clockwise) to increase delivery

pressure.

2. Turn the adjustment screw out (counter-clockwise) to decrease

the delivery pressure. When pressure adjustment is completed,

tighten jam nut on adjustment screw and replace protective cap.

Flow rates are not critical during pressure setting. The approximate min-

imum flow rates given in the table are for the main valve on which the CRA

is installed.

Valve Size

1

1

⁄

4

"-3"

4"-8"

10"-16"

Minimum Flow GPM

15-30

50-200

300-650

MAINTENANCE

Disassembly

To disassemble follow the sequence of the item numbers assigned to

parts in the sectional illustration.

Reassembly

Reassembly is the reverse of disassembly. Caution must be taken to

avoid having the yoke (17) drag on the inlet nozzle of the body (18).

Follow this procedure:

1. Place yoke (17) in body and screw the disc retainer assembly

(16) until it bottoms.

2. Install gasket (14) and spring (19) for 2-30 psi range onto plug

(13) and screw into body. Disc retainer must enter guide hole in

plug as it is assembled. Screw the plug in by hand. Use wrench

to tighten only.

3. Place gasket (25) and powertrol body (21) on yoke extension

(17). Refer to sectional view for proper reassembly of (21) onto

body (18).

4. Place lower diaphragm washer (24), "o" ring (22), diaphragm

(12), upper diaphragm washer (11), and belleville washer (20) on

yoke extension (17). Screw on diaphragm nut (10) finger tight.

5. Place two machine screws (4) through (21) (25) and screw into

body (18). Do not include the diaphragm (12) in this operation.

This holds parts aligned for next step, and allows the diaphragm

to move and be properly located during tightening of nut (10).

6. Hold the diaphragm so that screw holes in the diaphragm (12)

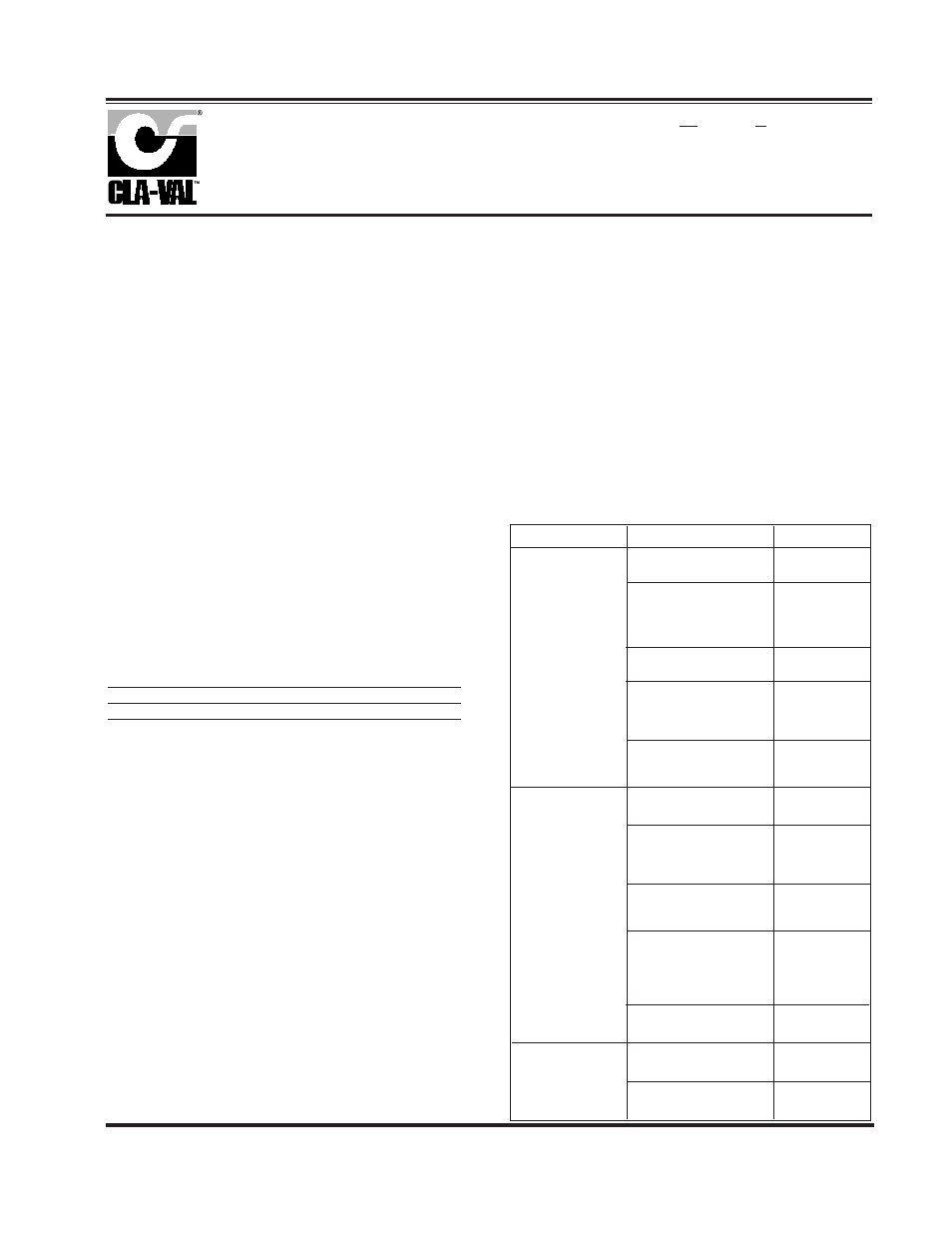

SYMPTOM

PROBABLE CAUSE

REMEDY

Fails to open when

pressure lowers

No spring compression

Tighten adjusting

screw

Mineral buildup on yoke

extension (17)

Disassemble and

clean part,

Replace "O" rings

(22) and (23).

Damaged spring

Disassemble and

replace.

Spring guide (8) is not in

place

Disassemble and

place guide (8) on

top of spring (9).

Yoke dragging on inlet

nozzle

Disassembled

and reassemble

use procedure.

Fails to close when

delivery pressure rises Spring compressed

Back off adjusting

screw

Mineral deposit on yoke

extension (17)

Disassemble and

clean part.

Replace "o" rings

(22) and (23).

Mechanical obstruction

Disassemble and

remove obstruc-

tion

Worn disc

Disassemble,

remove and

replace disc

retainer assem-

bly. (16)

Yoke dragging on inlet

nozzle

Refer to para-

graph 6

Damaged diaphragm (12)

Disassemble and

replace

Loose diaphragm nut (10) Remove cover

and tighten nut

REMOTE SENSING TYPE

CRA

Leakage from cover

vent hole

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2008 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-CRA (R-1/08)

and powertrol body (21) align. Tighten diaphragm nut (10) with a wrench.

At the final tightening release the diaphragm and permit it to rotate

approximately 5° to 10°. The diaphragm holes should now be properly

aligned with the body holes.

To check for proper alignment proceed as follows:

Rotate diaphragm clockwise and counterclockwise as far as possible.

Diaphragm screw holes should rotate equal distance on either side of

powertrol body screw holes ±1/8".

Repeat assembly procedure until diaphragm and yoke are properly

aligned. There must be no contact between yoke and body nozzle during

its normal opening and closing movement. To simulate this movement

hold powertrol body and diaphragm holes aligned. Move yoke to open

and closed positions. There must be no evidence of contact or dragging.

7. Remove machine screws per step 5.

8. Install spring (9) with spring guide (8) on top of spring.

9. Install cover (5) using eight machine screws (4).

10. Replace adjusting screw (2) and nut (3), then cap (1).

Pressure Reducing Control