Bell & Gossett HT 205B SM Models ACA Straight Tube, Removable Bundle Heat Exchangers User Manual

Page 4

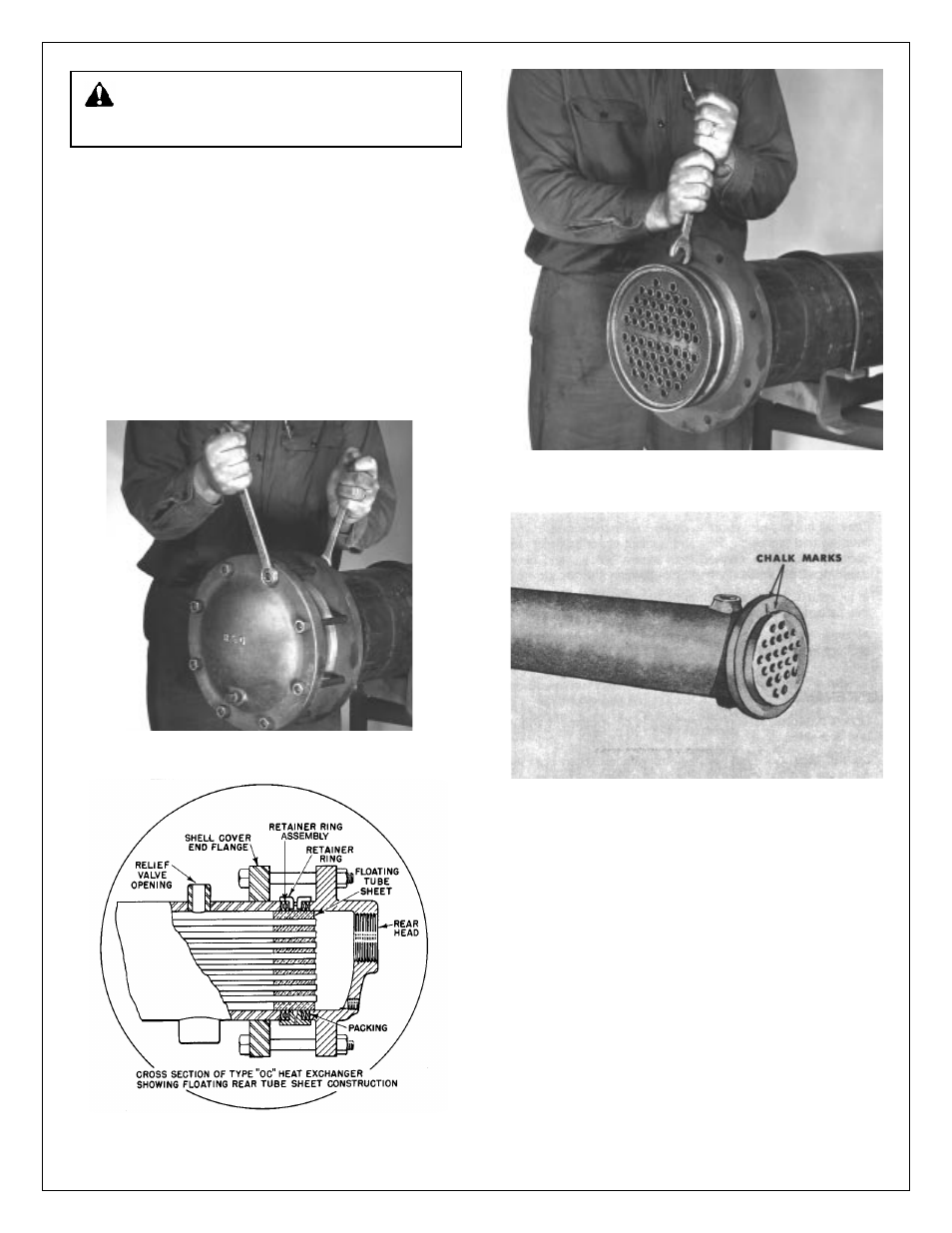

c. Remove packing (G) and retaining rings (H). It may be nec-

essary to tap lightly on the retainer rings for starting their

removal. More detail of floating tube sheet is given in Illus-

tration No. 3. Illustration No. 4 shows the method of prying

retainer rings off. If tapping is necessary, be sure to tap

evenly about the circumference so the retainer ring does

not bind on the floating tube sheet.

d. Mark tube sheet (B) and shell flange for later re-alignment.

Illustration No. 5.

e. Use chain jack. One suitable is Coffing Hoist, Model MA-15

3

/

4

ton capacity. Place short piece of 4x4 hardwood (oak)

between chain of jack and floating tube sheet (E). See

Illustration No. 1. Use longer 4x4 pieces as bundle is

removed. Support the bundle by lifting or resting on the

stationary tube sheet (B), as bundle is pushed out. Illus-

tration No. 6.

CAUTION: Failure to follow the procedures mentioned

in steps 8a, b, and c may result in damage to the tubes

or tube joints leading to premature failure of the heat

exchanger.

9. Removing the tube bundle:

Refer to drawings on pages 6 and 7 giving part names of

models MEAH, OC, GC and ACA. The model MEAH tube

bundles are more difficult to remove than the other models.

The MEAH exchanger has the horizontal baffles (N) extending

from the stationary tube steel (B) to about 5 inches of the

packed floating tube sheet (E). Two rubber baffle strips (O) are

adhered to the horizontal steel baffle (N). The rubber baffle

strips seal the space between the shell and horizontal baffle,

and prevent liquid by-passing. These rubber baffle strips (O)

in the MEAH act as brakes against the shell (C) making bundle

removal more difficult.

a. If the exchanger is difficult to work upon, hoist it into the

open after disconnecting piping.

b. Remove front (A) and rear (F) heads. See Illustration No. 2.

Illustration No. 2 – Removing rear head (completely remove front and

rear heads).

Illustration No. 3 – Cross section of type “OC” Heat Exchanger showing

rear tube sheet construction. (See packing retainer detail)

Illustration No. 5 – Marking of tube sheet and shell flange.

Illustration No. 4 – Prying off retainer rings.

4