Bell & Gossett HT 205B SM Models ACA Straight Tube, Removable Bundle Heat Exchangers User Manual

Page 3

3. Provide convenient means for frequently cleaning heat

exchangers as suggested below:

a. Circulating hot wash oil or light distillate through tubes or

shell at good velocity will effectually remove sludge or

other similar soft deposits.

b. Soft salt deposits may be washed out by circulating hot

fresh water.

c. Some cleaning compounds on the market, such as

“Oakite” may be used to advantage for removing sludge or

coke, provided hot wash oil or water, as described above,

does not give satisfactory results.

d. If none of the above described methods are effective for

the removal of hard scale or coke a mechanical means

may be used. The interior of the tubes may be rodded.

WARNING: Care must be exercised when handling

certain fluids. Follow manufacturers instructions. Use

eye and skin protection. Wear a respirator when required.

4. To clean or inspect inside of tubes, remove channel cover and

rear head. On exchangers having bonnet type heads (without

channel cover), piping must be disconnected and both heads

removed.

5. Do not attempt to clean tubes by blowing steam through indi-

vidual tubes. This overheats the tube and results in tube

expansion strains and sometimes leaking tubes.

6. Frequently and at regular intervals, observe interior and exte-

rior condition of all tubes and keep them clean. Frequency of

cleaning should be according to scale build-up.

CAUTION: Neglect in keeping all tubes clean may

result in complete stoppage of flow through some

tubes with consequent overheating of these tubes, resulting

in severe expansion strains, leaking tube joints, and damage

to the heat exchanger.

7. Exchangers subject to fouling or scaling should be cleaned

periodically. A light sludge or scale coating on the tube greatly

reduces its effectiveness. A marked increase in pressure drop

and/or reduction in performance usually indicates cleaning is

necessary, if the unit has been checked for air or vapor bind-

ing and this has been found not to be the cause. Since the dif-

ficulty of cleaning increases rapidly as the scale thickens or

deposits increases, the interval between cleanings should not

be excessive.

8. Tube bundle removal:

a. During bundle removal, the dead weight of bundle should

never be supported on individual tubes since the tubes are

small and of relatively thin metal. Rest the bundle on the

tube sheet, support plates, or wood blocks cut to fit

periphery of the bundle.

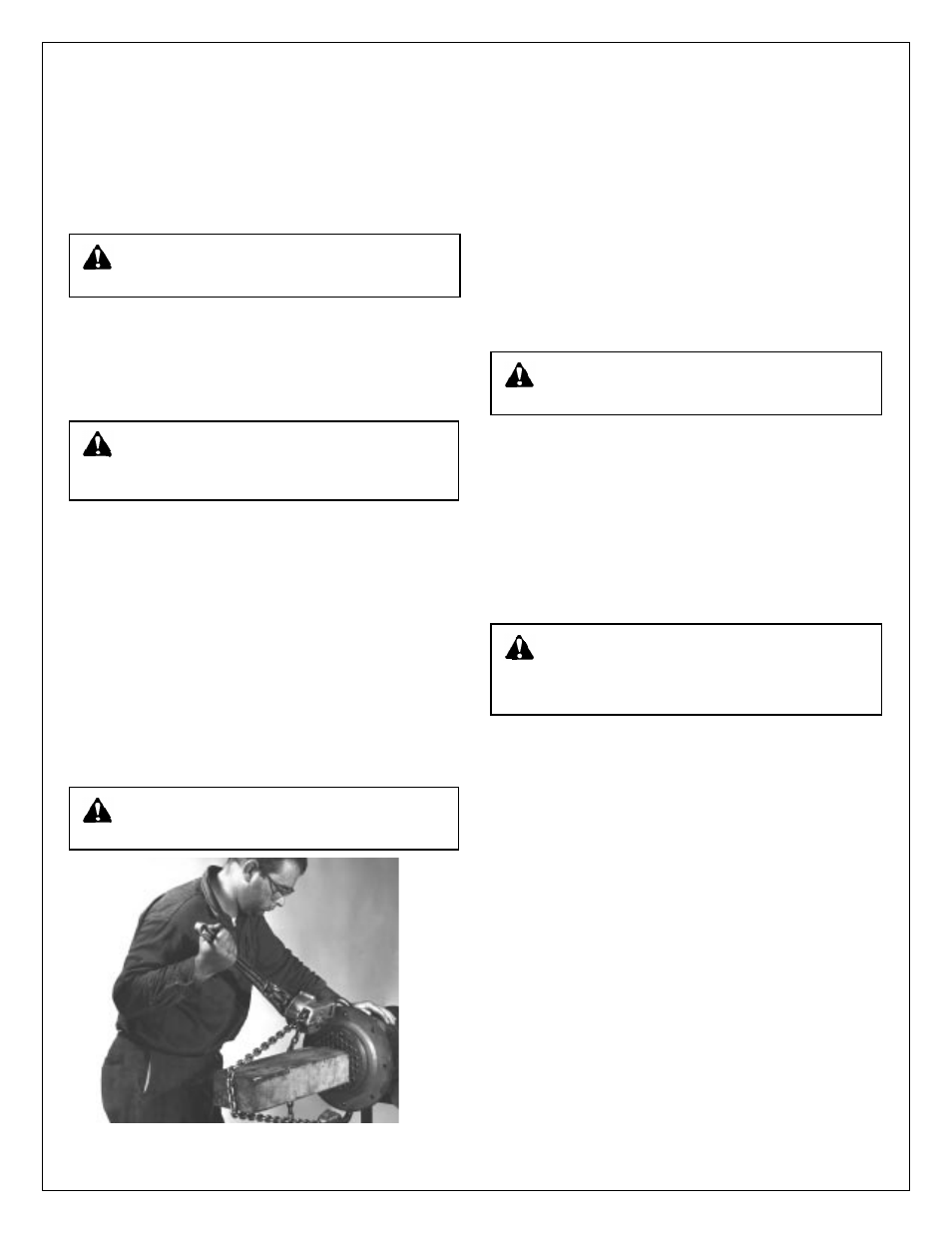

b. Be sure there is a soft wood filler between ends of tubes

and steel bearing plate when pushing bundle out. On

smaller bundles of 12" diameter and under, it is permis-

sible to use hard wood block in place of wood filler and

steel bearing plates. See Illustration No. 1.

c. Tube bundles may be raised using slings formed by bend-

ing light plates into a “U” form and attaching lifting lugs to

the ends of the sheets. Baffles can be easily bent and dam-

aged if dragged over rough surfaces.

OPERATION

1. When placing a unit in operation, open the vent connections

and start to circulate the cold medium only. Be sure that the

passages in the exchanger are entirely filled with the cold fluid

before closing the vents. The hot medium should then be intro-

duced gradually until all passages are filled with liquid, close

vents and slowly bring the unit up to temperature.

2. Start operation gradually. Do not admit hot fluid to the unit

suddenly when empty or cold. Do not shock unit with cold fluid

when unit is hot.

CAUTION: Fluids must be gradually introduced to the

unit. Failure to do so can cause damage to the heat

exchanger.

3. In shutting down, flow of hot medium should be shut off first.

If it is necessary to stop circulation of cooling medium the cir-

culation of hot medium should also be stopped by by-passing

or otherwise.

4. Do not operate equipment under conditions in excess of those

specified on nameplate.

WARNING: Failure to operate the heat exchanger

within the design pressure and temperature on the

nameplate may result in damage to the heat exchanger and

potential injury to adjacent personnel.

5. Drain all fluids when shutting down to eliminate possibility of

freezing and corrosion. To guard against water hammer, con-

densate should be drained from steam heaters and similar

apparatus both when starting up and when shutting down.

6. In all installations there should be no pulsation of fluids since

this causes vibration and strain with resulting leaks.

7. All gasketed joints should be checked after starting for leaks

and tightened if necessary.

MAINTENANCE

1. Do not open heads until all pressure is off equipment and the

unit is drained.

2. Do not blow out heat exchangers with air when operating

fluids are of a flammable or otherwise hazardous nature.

WARNING: Proper precautions must be taken (special

clothing, equipment, etc.) to protect personnel from

injury due to escaping fluids.

3

Illustration No. 1 – The method employed to push tube bundle out

of shell.