6 maintenance, Advanced instruments inc – Analytical Industries GPR-2800 AIS ATEX Oxygen Analyzer User Manual

Page 31

Advanced Instruments Inc.

31

6 Maintenance

Generally, cleaning the electrical contacts or replacing filter elements is the extent of the maintenance requirements of this

transmitter.

Sensor Replacement

Periodically, the oxygen sensor will require replacement. The operating life is determined by a number of factors that are

influenced by the user and therefore difficult to predict. The Features & Specifications define the normal operating conditions

and expected life of the standard sensor utilized by the GPR-2800AIS transmitter. Expected sensor life is inversely proportional

to changes in oxygen concentration, pressure and temperature.

Serviceability: Except for replacing the oxygen sensor, there are no parts inside the transmitter for the operator to service.

Only trained personnel with the authorization of their supervisor should conduct maintenance.

Caution: DO NOT open the oxygen sensor. The sensor contains a corrosive liquid electrolyte that could be harmful if touched

or ingested, refer to the Material Safety Data Sheet contained in the Owner’s Manual. Avoid contact with any liquid or crystal

type powder in or around the sensor or sensor housing, as either could be a form of electrolyte. Leaking sensors should be

disposed of in accordance with local regulations.

Procedure:

1. Remove the four (4) screws securing the transmitter’s front panel.

2. Caution: Do not discard the gaskets from the enclosure.

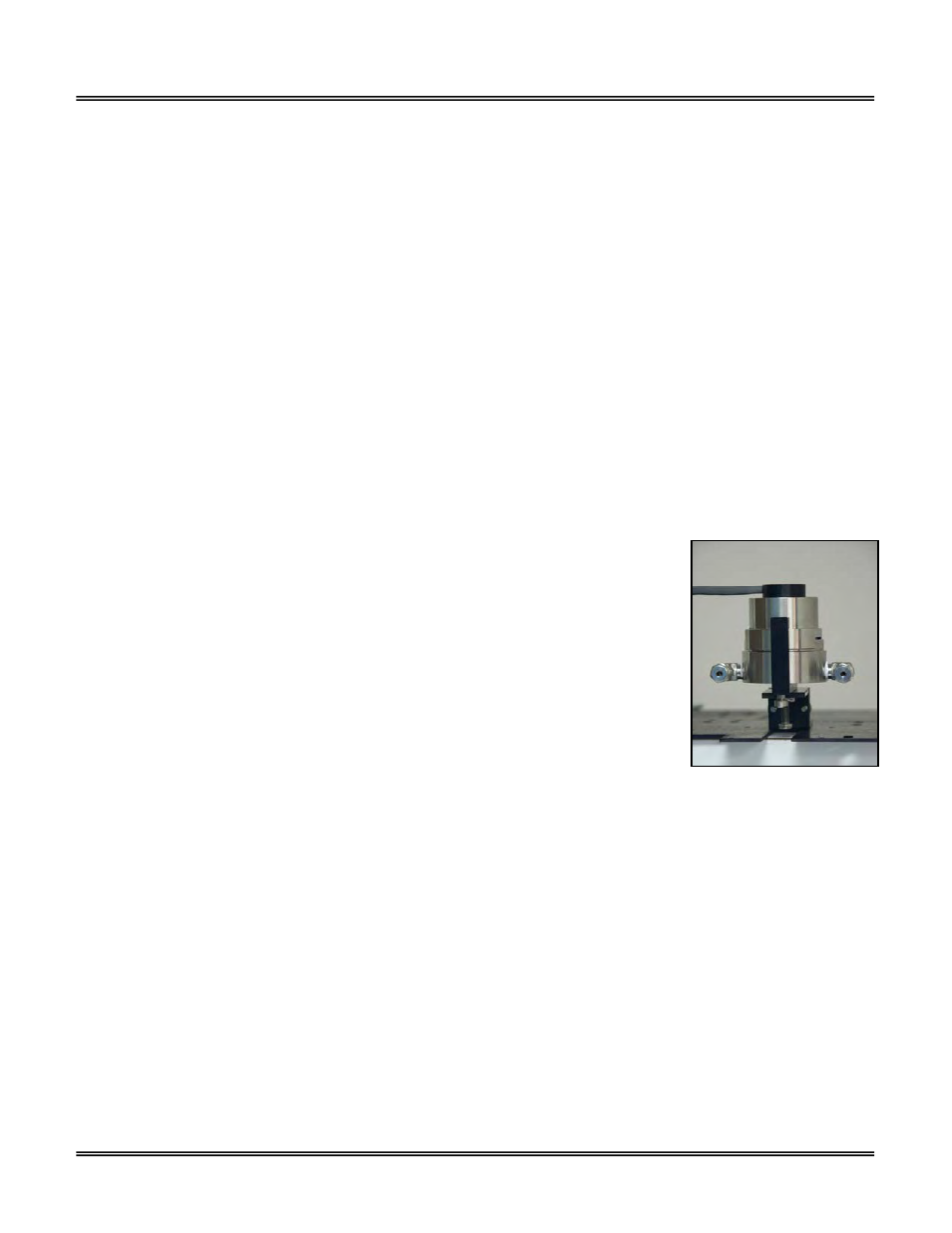

3. Using the 5/16 wrench supplied loosen but do not remove the clamp bolt located in the

center of the housing with the elbows attached.

4. Rotate the upper section of the sensor housing 90º to disengage from the clamp.

5. Remove the upper section by pulling it straight up and place it on a smooth surface.

6. Remove the old oxygen sensor and dispose of it as you would a battery.

7. Remove the new oxygen sensor from the shipping bag.

8. Remove the red label and the gold ribbon (shorting device) from the PCB at the rear of the

sensor.

9. Caution: Minimize the time the sensor is exposed to ambient air.

10. Place the new sensor in the bottom section of the sensor housing with the PCB facing up.

11. Place the upper section of the sensor housing over the sensor.

12. Span Calibrate the transmitter in 20.9% ambient air, once the reading stabilizes – see

above.

13. Gently push the upper section downward and rotate 90º to engage the clamp.

14. Finger tighten the clamp bolt and one full turn with the 5/16 wrench to compressed the o-ring seal.

15. Connect zero gas or low oxygen content sample gas line to purge the sensor of oxygen.