Advanced instruments inc, Mounting the transmitter – Analytical Industries GPR-2800 AIS ATEX Oxygen Analyzer User Manual

Page 11

Advanced Instruments Inc.

11

Caution: If the transmitter is equipped with an optional flow indicator with integral metering valve or a metering flow control

valve upstream of the sensor - open the metering valve completely to avoid drawing a vacuum on the sensor and placing an

undue burden on the pump.

If pump loading is a consideration, a second throttle valve on the pump’s inlet side may be necessary to provide a bypass path

so the sample flow rate is within the above parameters.

Recommendations to avoid erroneous oxygen readings and damaging the sensor:

¾ Do not place your finger over the vent (it pressurizes the sensor) to test the flow indicator when gas is flowing to the

sensor. Removing your finger (the restriction) generates a vacuum on the sensor and may damage the sensor (voiding the

sensor warranty).

¾ Assure there are no restrictions in the sample or vent lines

¾ Avoid drawing a vacuum that exceeds 14” of water column pressure – unless done gradually

¾ Avoid excessive flow rates above 5 SCFH which generate backpressure on the sensor.

¾ Avoid sudden releases of backpressure that can severely damage the sensor.

¾ Avoid the collection of liquids or particulates on the sensor, they block the diffusion of oxygen into the sensor.

¾ If the transmitter is equipped with an optional integral sampling pump (positioned downstream of the sensor) and a flow

control metering valve (positioned upstream of the sensor), completely open the flow control metering valve to avoid

drawing a vacuum on the sensor and placing an undue burden on the pump.

Moisture & Particulates: Installation of a suitable coalescing or particulate filter is required to remove condensation, moisture

and/or particulates from the sample gas to prevent erroneous analysis readings and damage to the sensor or optional

components. Moisture and/or particulates do not necessarily damage the sensor, however, collection on the sensing surface

can block or inhibit the diffusion of sample gas into the sensor resulting in a reduction of sensor signal output – and the

appearance of a sensor failure when in fact the problem is easily remedied by blowing on the front of the sensor. Consult the

factory for recommendations concerning the proper selection and installation of components.

Gas Connections: Inlet and outlet vent gas lines for % analysis require 1/8” or ¼” stainless steel compression fittings; hard

plastic tubing with a low permeability factor can be used percentage range measurements.

Power Connection: Locate the appropriate power source to meet the analyzer or transmitter requirements, ensure that is

properly grounded and meets the area classification.

Mounting the Transmitter

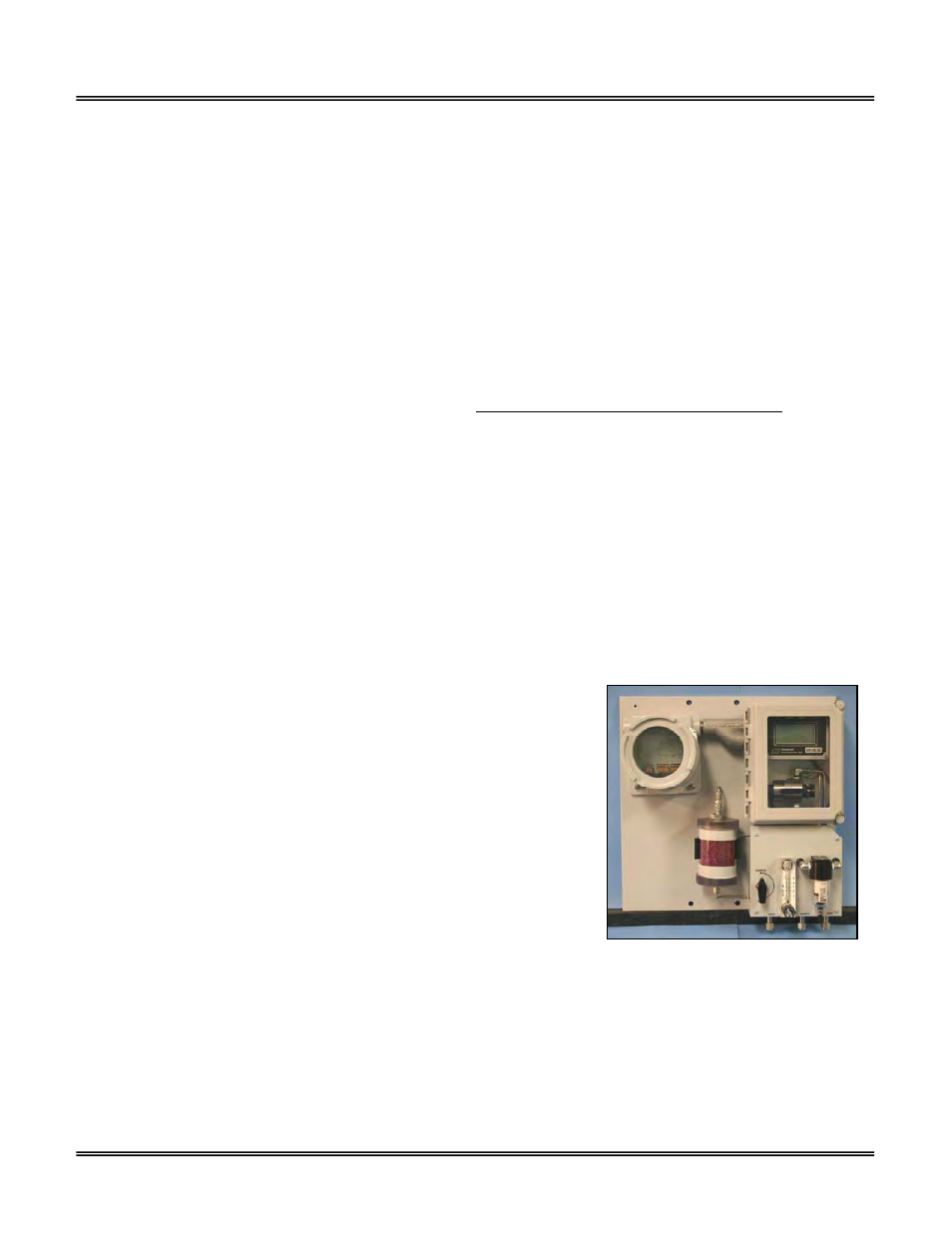

The GPR-2800AIS consists of two interconnected enclosures (without the optional

sample conditioning system and panel) and measures 8”H x 15-3/4”W x 7”D. This

configuration is designed to be mounted directly to any flat vertical surface, wall or

bulkhead plate with eight (8) of the appropriate screws. To facilitate servicing the

interior of the transmitters, position it approximately 5 feet off ground level.

Remove the four (4) screws securing the top section of the enclosure, set them

aside for reinstallation and raise the hinged top section 180º until it locks in place.

Locate the mounting holes cast into the enclosure.

Secure the enclosure to a vertical surface approximately 5 feet from the floor or a level accessible to service personnel. This

requires the user to supply four (4) additional proper size screws and anchors.

Caution: Do not remove or discard the gaskets from either the enclosure or junction box. Failure to reinstall either gasket will

void the NEMA 4 rating and RFI protection. The transmitters design provides protection from RFI that is maintained by leaving

specific mating areas of the enclosure unpainted to maintain conductivity the gasket, top and bottom sections of the enclosure.

These unpainted areas are protected by gaskets and contribute to maintaining the NEMA 4 rating. Do not paint these areas.

Painting will negate the RFI protection.

Note: If equipped with the optional H2S sample conditioning system, the transmitter and sample system are mounted to a back

panel which has four (4) holes for mounting the 15-3/4”H x 15-3/4”W x 7”D panel to any vertical flat surface.