OSRAM ORBEOS Components User Manual

Page 9

9

OLED INTEGRATION

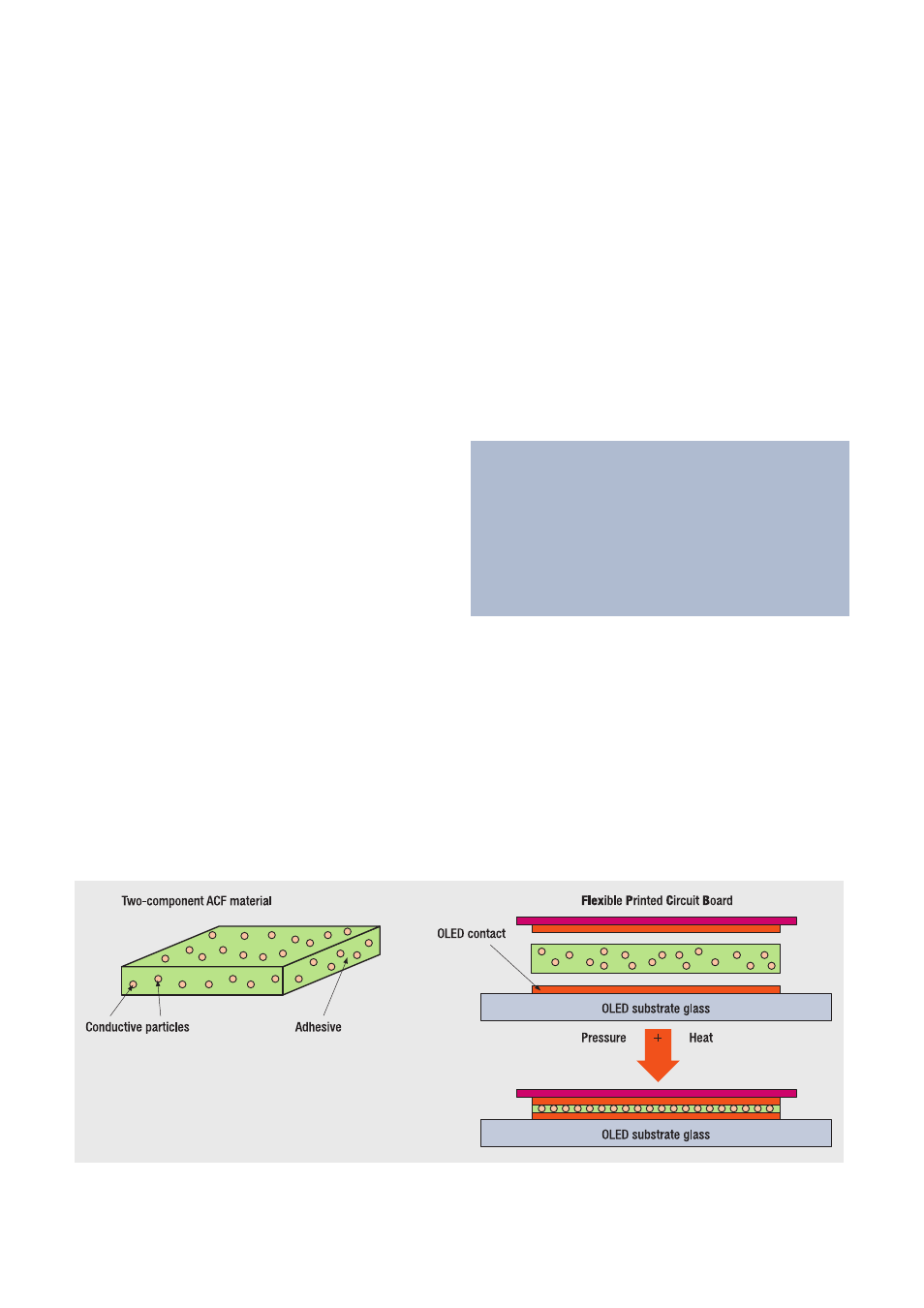

Flex-PCBs are applied by a special conductive polymer mate-

rial in a thermo-compression process called ACF bonding

(anisotropic conductive fi lm bonding), which is well known

from the display industry: First, a two-component material is

dispensed at the contact pad of the OLED. Then, the Flex-PCB

is adjusted to the contact pad. Afterwards, heat and pressure

is applied on the connection by a heated stamp (bonding

tool, fi gure 7).

ORBEOS

®

devices are available with PCB. In case an indivi-

dual PCB design is desired, and for more details on the

material and process conditions, the following links regarding

ACF may be helpful:

http://www.hitachi-chem.co.jp/english/products/do/001.html

http://www.sonycid.jp/en/products/dd1/

For more details on ACF/heatseal bonding equipment, please

refer to, e.g.:

http://www.miyachieurope.com/products/hot-bar/

Fig. 7. Application of Flex-PCB on the OLED contacts via ACF bonding.

Thermal management:

Heat sinks as known from LED technology are not obligatory, since

OLEDs are cooled passively by heat convection and radiation from

both of their surfaces. A device, which is driven at typical operation

conditions (1000 cd/m

2

luminance), heats up by between 5 K and

15 K above ambient temperature. In general, the design of the OLED

application should enable suffi cient heat transport from the surfaces.

Please also see the section: 4.2.2. Ambient temperature.