OSRAM ORBEOS Components User Manual

Page 6

6

OLED INTEGRATION

On the following pages, several techniques for interconnec-

ting OLEDs are described. To interconnect OLED devices,

their contact surfaces have to be free of dust and grease.

If necessary, use isopropyl alcohol (IPA) to carefully wipe the

contact ledges clean.

1.3. Interconnection

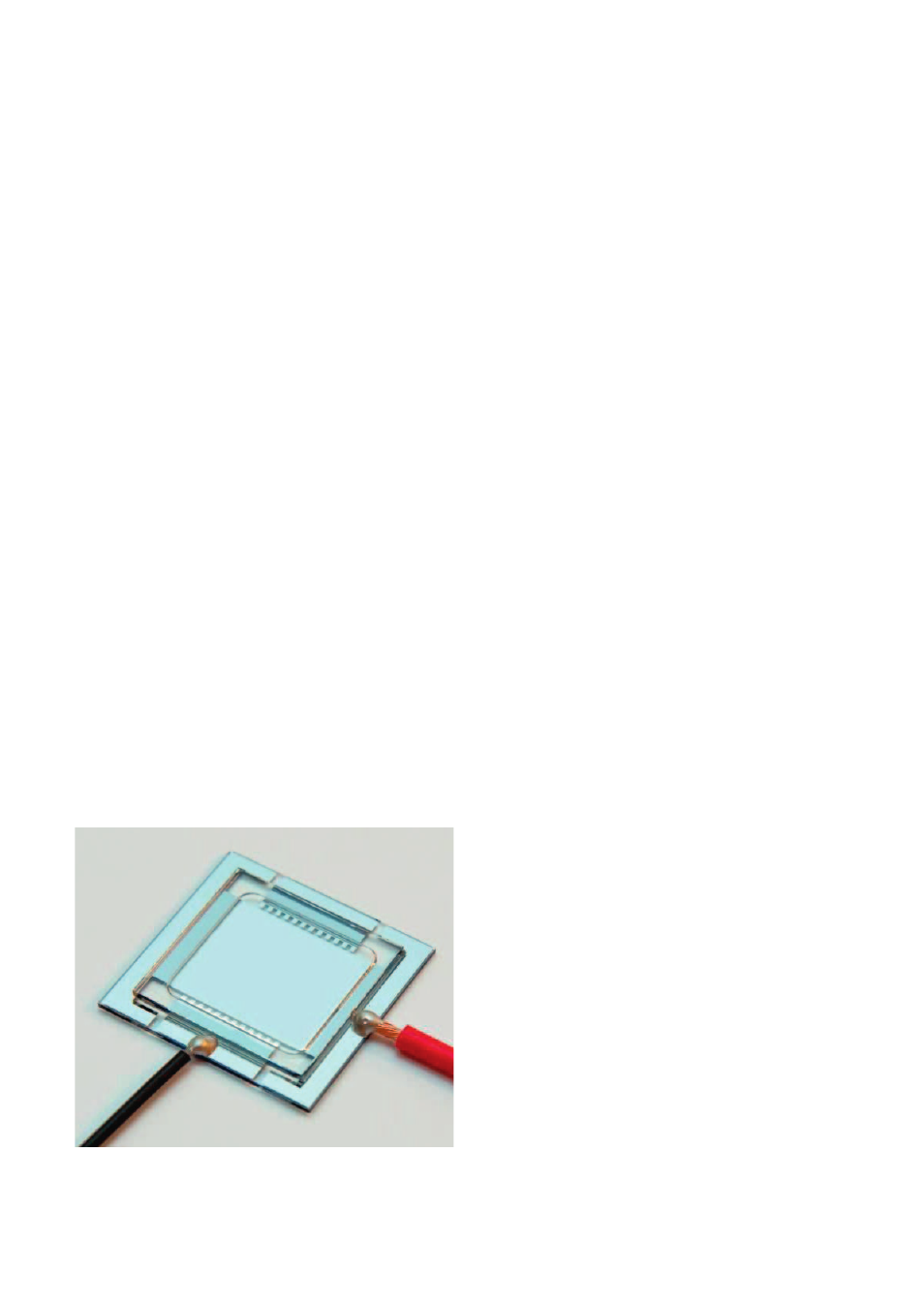

1.4. Contacting of OLED tiles via conductive glue

In general, the interconnection should be applied without heat

introduction into the active area of the device. Furthermore,

avoid mechanical stress. Exercise caution in order to avoid

glass chipping and breakage when applying the interconnec-

tion at the substrate edges.

The conductive epoxy used in this application example can

be obtained through R+S Components (conductive epoxy

CW2400, Stock No.: 496-265).

Mix equal amounts of part A and part B thoroughly for at least

2 minutes. The mixed components have to be applied within

a short period. The pot life is only 10 minutes at 24 °C. After-

wards, apply the epoxy to the contact surface and attach

the wire. For better adhesion, fan out the strands of the wire

slightly before attaching it. The wire should have a cross-

sectional area of 0.25 – 0.5 mm². The curing time of the epoxy

is 4 hours at room temperature (24 °C). However, to achieve

maximum conductivity and adhesion, you may expose the ep-

oxy to a temperature of 66 °C – 80 °C for 10 minutes and sub-

sequently allow it to cool. Please note that the heat should be

applied to the contact ledges only.

Fig. 3. Rear side of an OLED device. Two wires are attached to the contact ledges with

conductive epoxy.