Tvs diode arrays, Lightning surge protection - srv05 series, Diodes) – Littelfuse SRV05 Series User Manual

Page 2

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 11/25/13

TVS Diode Arrays

(SPA

®

Diodes)

Lightning Surge Protection - SRV05 Series

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress only rating and operation of the device

at these or any other conditions above those indicated in the operational sections of this

specification is not implied.

1

Non-repetitive pulse per waveform on page 3

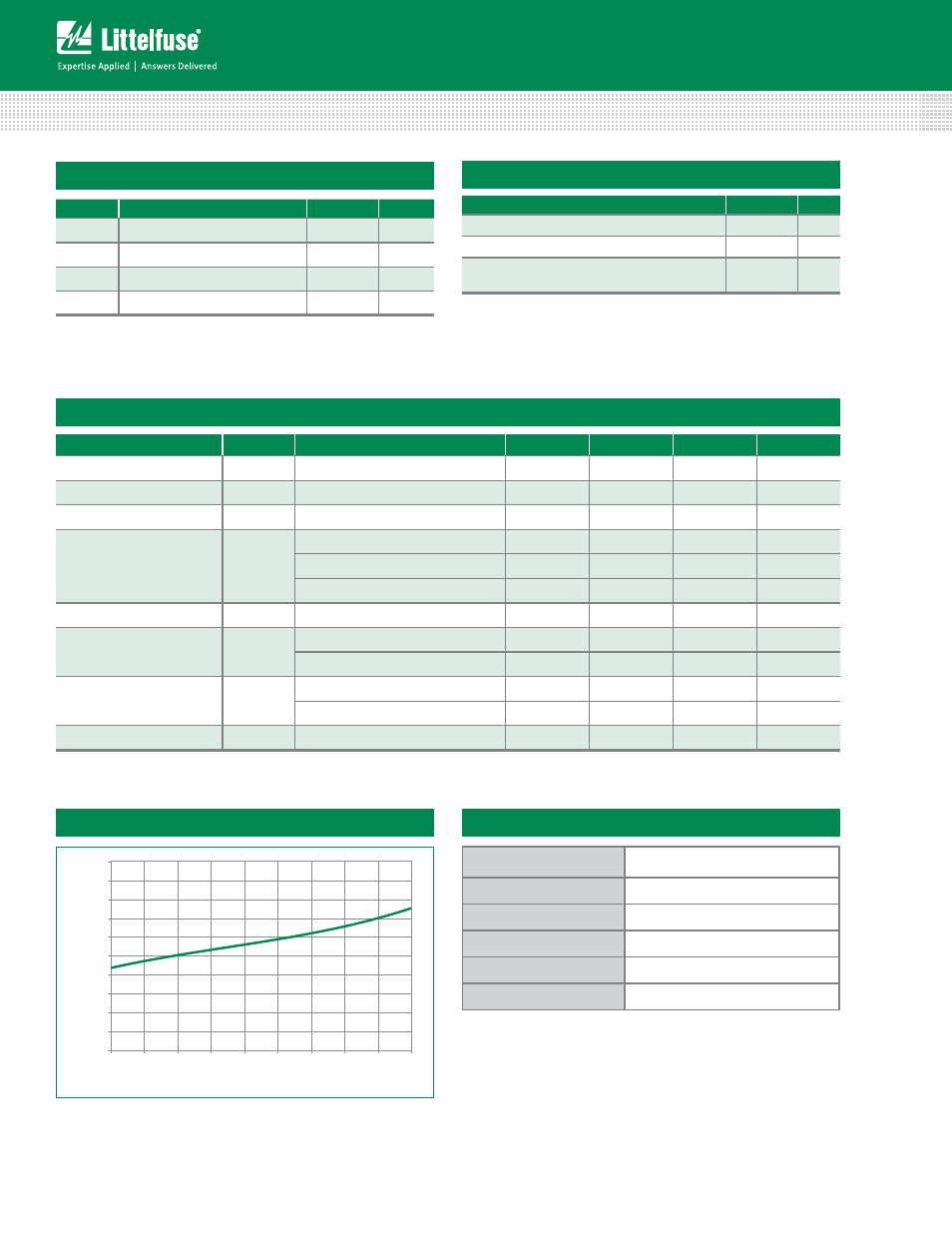

Absolute Maximum Ratings

Symbol

Parameter

Value

Units

I

PP

Peak Current (t

p

=8/20μs)

1

10

A

P

PK

Peak Pulse Power (t

p

=8/20μs)

150

W

T

OP

Operating Temperature

–40 to 125

°C

T

STOR

Storage Temperature

–55 to 150

°C

Thermal Information

Parameter

Rating

Units

Storage Temperature Range

–55 to 150

°C

Maximum Junction Temperature

150

°C

Maximum Lead Temperature

(Soldering 20-40s)

260

°C

Electrical Characteristics

(T

OP

=25ºC)

Parameter

Symbol

Test Conditions

Min

Typ

Max

Units

Reverse Standoff Voltage

V

RWM

I

R

≤ 1µA

6.0

V

Reverse Voltage Drop

V

R

I

R

= 1mA

8.0

V

Reverse Leakage Current

I

LEAK

V

R

=5V

0.1

0.5

µA

Clamp Voltage

1

V

C

I

PP

=1A, t

p

=8/20µs, I/O to GND

2

8.8

10.0

V

I

PP

=5A, t

p

=8/20µs, I/O to GND

2

11.5

13.0

V

I

PP

=8A, t

p

=8/20µs, I/O to GND

2

13.2

15.0

V

Dynamic Resistance

R

DYN

(V

C2

- V

C1

) / (I

PP2

- I

PP1

)

0.7

Ω

ESD Withstand Voltage

1

V

ESD

IEC61000-4-2 (Contact)

±20

kV

IEC61000-4-2 (Air)

±30

kV

Diode Capacitance

1

C

I/O-GND

Reverse Bias=0V

2.4

3.0

pF

Reverse Bias=1.65V

2.0

pF

Diode Capacitance

1

C

I/O-I/O

Reverse Bias=0V

1.2

pF

Notes:

1

Parameter is guaranteed by design and/or device characterization.

2

Repetitive pulse per waveform on page 3.

Clamping Voltage vs. I

PP

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

1 2 3 4 5 6 7 8 9 10

Peak Pulse Current-I

PP

(A)

Clamp Voltage (V

C

)

Product Characteristics

Lead Plating

Matte Tin

Lead Material

Copper Alloy

Lead Coplanarity

0.0004 inches (0.102mm)

Substitute Material

Silicon

Body Material

Molded Epoxy

Flammability

UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

5. Package surface matte finish VDI 11-13.