Varistor products, Thermally protected varistors > smov25s series, Wave solder profile – Littelfuse SMOV25S Varistor Series User Manual

Page 4: Lead–free profile, Non lead–free profile

© 2013 Littelfuse, Inc.

240

Revised: May 8, 2013

Varistor Products

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/smov25s.html for current information.

SMOV25S Varistor Series

Thermally Protected Varistors > SMOV25S Series

Operating/Storage Temp.

-45°C to +75°C / -45°C to +85°C

Passive Aging

+75°C, 1000 hours

-/+10% typical voltage change

Humidity Aging

+75°C, 85%R.H., 1000 hours

-/+10% typical voltage change

Thermal Shock

+75°C to -40°C 5 times

-/+10% typical voltage change

Solvent Resistance

MIL-STD-202, Method 215F

Moisture Sensitivity

Level 1, J-STD-020C

Lead Material

Tin–coated Copper wire

Soldering

Characteristics

Solderability per MIL-STD-202,

Method 208E

Insulating Material

Cured, flame retardant epoxy polymer

meets UL94V-0 requirements

Device Labeling

Marked with LF, voltage, UL logos, and

date code

Physical Specifications

Environmental Specifications

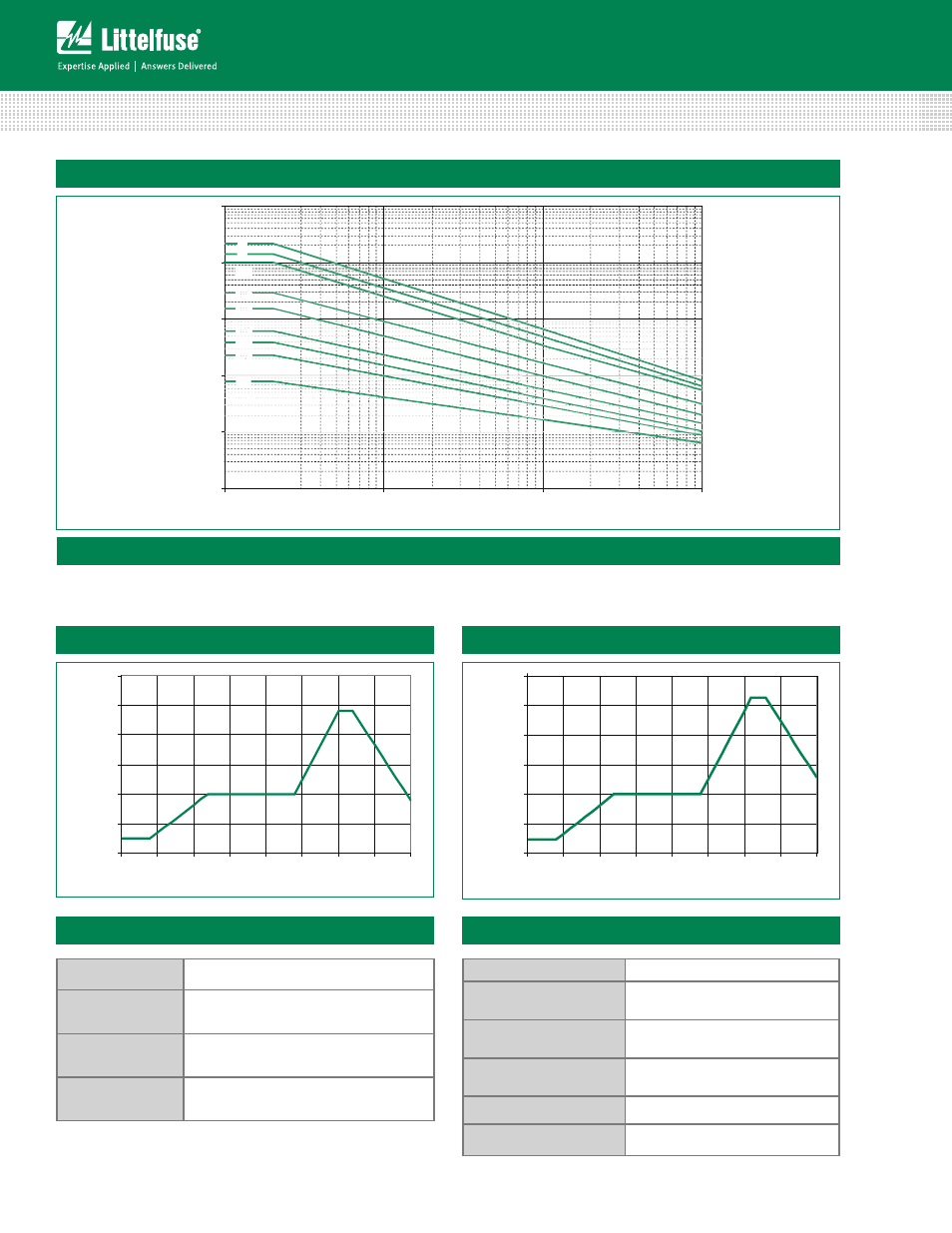

SMOV25S Pulse Rating Curve

1

2

∞

15

10

2

10

3

1

10

100

1000

10000

100000

10

100

1000

10000

Impulse Duration (secs)

10

4

10

5

10

6

Figure 4

Wave Solder Profile

Because the SMOV25S Series varistors contain a thermal protec-

tion device, care must be taken when soldering the devices into

place. Two soldering methods are possible. Firstly, hand soldering:

0

50

100

150

200

250

300

0

0.5

1

1.5

2

2.5

3

3.5

4

TIME(MINUTES)

T

E

M

P

E

RAT

URE

(

ºC)

Maximum Wave 240C

Lead–free Profile

0

50

100

150

200

250

300

0

0.5

1

1.5

2

2.5

3

3.5

4

TIME(MINUTES)

T

EMPER

A

T

U

R

E

(º

C

)

Maximum Wave 260C

Non Lead–free Profile

It is recommended to heat–sink the leads of the device. Secondly,

wave–soldering: It is critically important that all preheat stage and

the solder bath temperatures are rigidly controlled.

Figure 5

Figure 6