Tvs diode arrays, General purpose esd protection - sp720 series, Diodes) – Littelfuse SP720 Lead-Free_Green Series User Manual

Page 6: Sp720

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 04/24/13

TVS Diode Arrays

(SPA

®

Diodes)

General Purpose ESD Protection - SP720 Series

Part Numbering System

Lead Plating

Matte Tin

Lead Material

Copper Alloy

Lead Coplanarity

0.004 inches (0.102mm)

Substitute Material

Silicon

Body Material

Molded Epoxy

Flammability

UL 94 V-0

Product Characteristics

Ordering Information

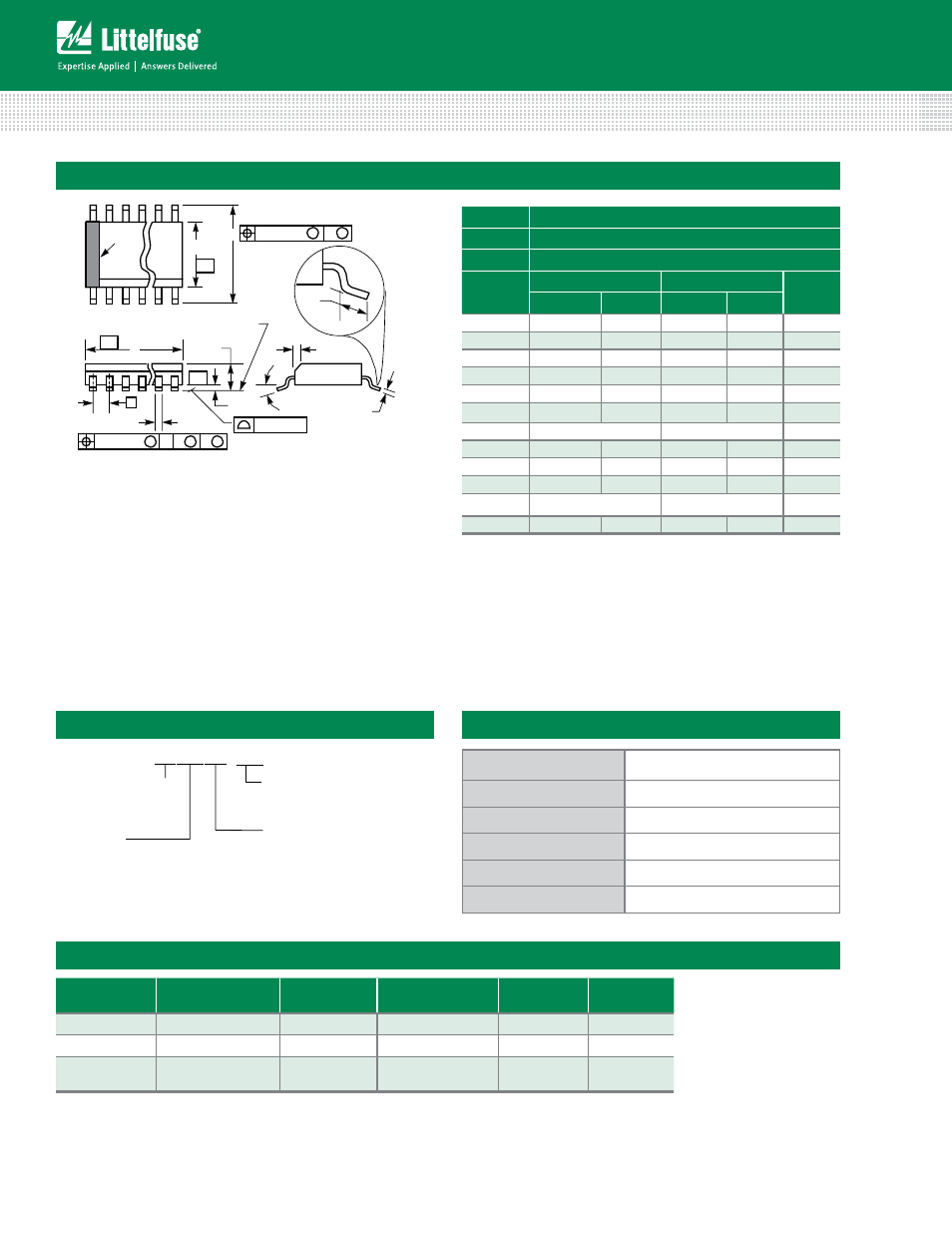

Package Dimensions — Small Outline Plastic Packages (SOIC)

Notes:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of Publication

Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs. Mold flash,

protrusion and gate burrs shall not exceed 0.15mm (0.006 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and

protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index feature must be

located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater above the seating

plane, shall not exceed a maximum value of 0.61mm (0.024 inch).

10. Controlling dimension:MILLIMETER. Converted inch dimensions are not necessarily

exact.

Package

SOIC

Pins

16

JEDEC

MS-012

Millimeters

Inches

Notes

Min

Max

Min

Max

A

1.35

1.75

0.0532

0.0688

-

A1

0.10

0.25

0.0040

0.0098

-

B

0.33

0.51

0.013

0.020

9

C

0.19

0.25

0.0075

0.0098

-

D

9.80

10.00

0.3859

0.3937

3

E

3.80

4.00

0.1497

0.1574

4

e

1.27 BSC

0.050 BSC

-

H

5.80

6.20

0.2284

0.2440

-

h

0.25

0.50

0.0099

0.0196

5

L

0.40

1.27

0.016

0.050

6

N

16

16

7

µ

0º

8º

0º

8º

-

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater above

the seating plane, shall not exceed a maximum value of 0.61mm

(0.024 inch).

10. Controlling dimension:MILLIMETER. Converted inch dimensions are

not necessarily exact.

INDEX

AREA

E

D

N

1

2

3

-B-

0.25(0.010)

C A

M

B S

e

-A-

L

B

M

-C-

A1

A

SEATING PLANE

0.10(0.004)

h x 45

o

C

H

0.25(0.010)

B

M

M

µ

Part Number

Temp. Range (ºC)

Package

Environmental

Informaton

Marking

Min. Order

SP720APP

-40 to 105

16 Ld PDIP

Lead-free

SP720AP(P)

1

1500

SP720ABG

-40 to 105

16 Ld SOIC

Green

SP720A(B)G

2

1920

SP720ABTG

-40 to 105

16 Ld SOIC

Tape and Reel

Green

SP720A(B)G

2

2500

SP720

Series

Package

P=Lead Free

G=Green

TG= Tape and Reel / Green

AB = 16 Ld SOIC

AP = 16 Ld PDIP

TVS Diode Arrays

(SPA

®

Diodes)

** **

See Ordering Information section for specific options available

Notes:

1. SP720AP(P) means device marking either SP720AP or SP720APP.

2. SP720A(B)G means device marking either SP720AG or SP720ABG which are good for types SP720ABG and SP720ABTG.