Tvs diode arrays, General purpose esd protection - sp1007 series, Diodes) – Littelfuse SP1007 Series User Manual

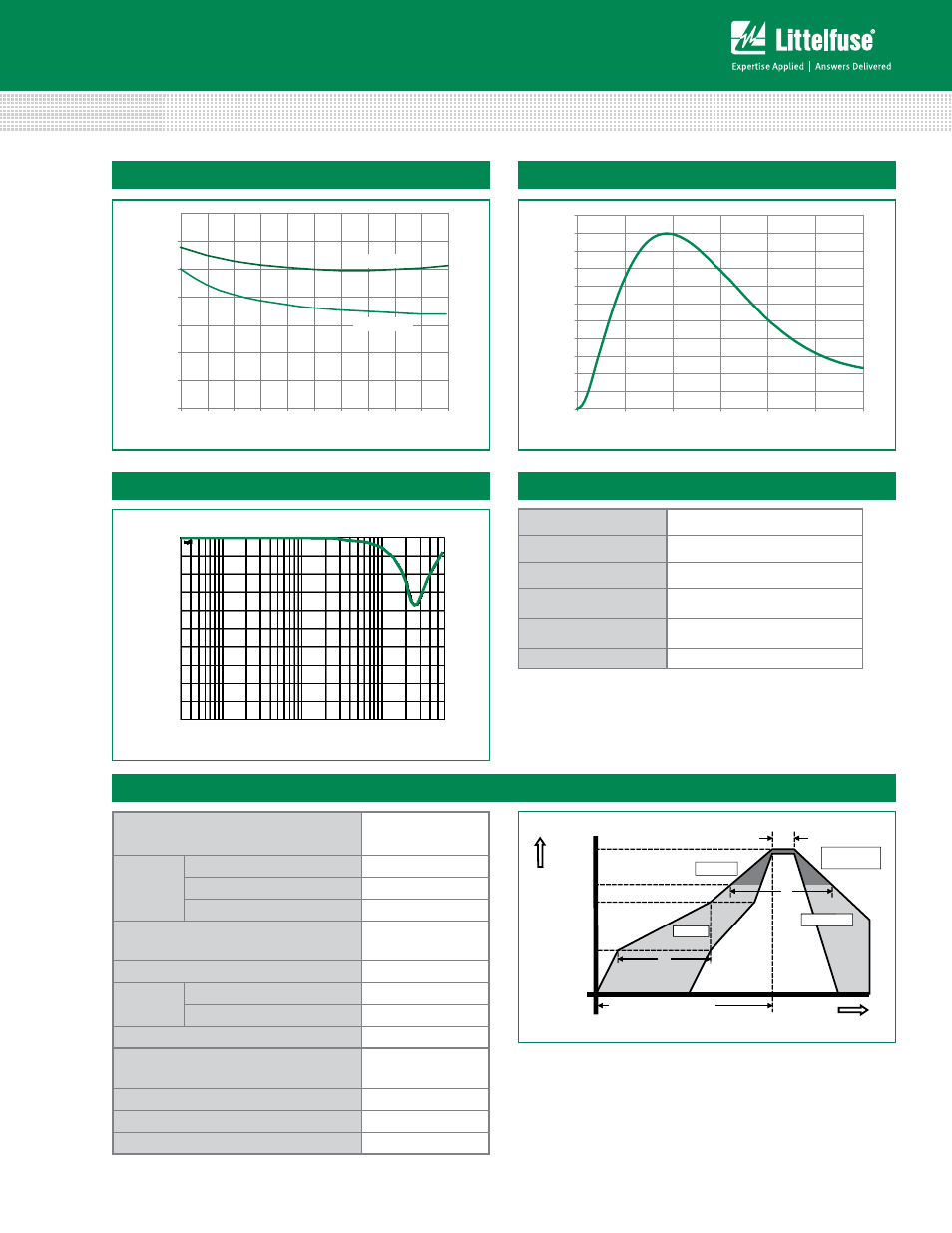

Page 3: Pulse waveform capacitance vs. reverse bias, Insertion loss (s21) i/o to gnd

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 11/22/13

TVS Diode Arrays

(SPA

®

Diodes)

General Purpose ESD Protection - SP1007 Series

Pulse Waveform

Capacitance vs. Reverse Bias

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Bias Voltage (V)

Capacitance (pF)

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

SP1007-01ETG

SP1007-01WTG

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

0.0 5.0 10.0 15.0 20.0 25.0 30.0

Time (μs)

Percent of

I

PP

Insertion Loss (S21) I/O to GND

Frequency (MHz)

At

tenuatio

n

(d

B)

-35

-30

-25

-20

-15

-10

-5

0

-40

-45

10

100

1000

Time

Te

mperatur

e

T

P

T

L

T

S(max)

T

S(min)

25

t

P

t

L

t

S

time to peak temperature

Preheat

Preheat

Ramp-up

Ramp-up

Ramp-down

Ramp-do

Critical Zone

T

L

to T

P

Critical Zone

T

L

to T

P

Reflow Condition

Pb – Free assembly

Pre Heat

- Temperature Min (T

s(min)

)

150°C

- Temperature Max (T

s(max)

)

200°C

- Time (min to max) (t

s

)

60 – 180 secs

Average ramp up rate (Liquidus) Temp

(T

L

) to peak

3°C/second max

T

S(max)

to T

L

- Ramp-up Rate

3°C/second max

Reflow

- Temperature (T

L

) (Liquidus)

217°C

- Temperature (t

L

)

60 – 150 seconds

Peak Temperature (T

P

)

260

+0/-5

°C

Time within 5°C of actual peak

Temperature (t

p

)

20 – 40 seconds

Ramp-down Rate

6°C/second max

Time 25°C to peak Temperature (T

P

)

8 minutes Max.

Do not exceed

260°C

Soldering Parameters

Product Characteristics of SOD-882 Package

Lead Plating

Pre-Plated Frame

Lead Material

Copper Alloy

Lead Coplanarity

0.0004 inches (0.102mm)

Substitute Material

Silicon

Body Material

Molded Epoxy

Flammability

UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

5. Package surface matte finish VDI 11-13.