Pulseguard, Suppressors, Surface mount polymeric esd suppressors – Littelfuse PGB20402 Series User Manual

Page 3

www.littelfuse.com

©2011 Littelfuse

PGB2 Series

Specifications are subject to change without notice.

3

Revised: March 8, 2011

PulseGuard

®

Suppressors

Surface Mount Polymeric ESD Suppressors

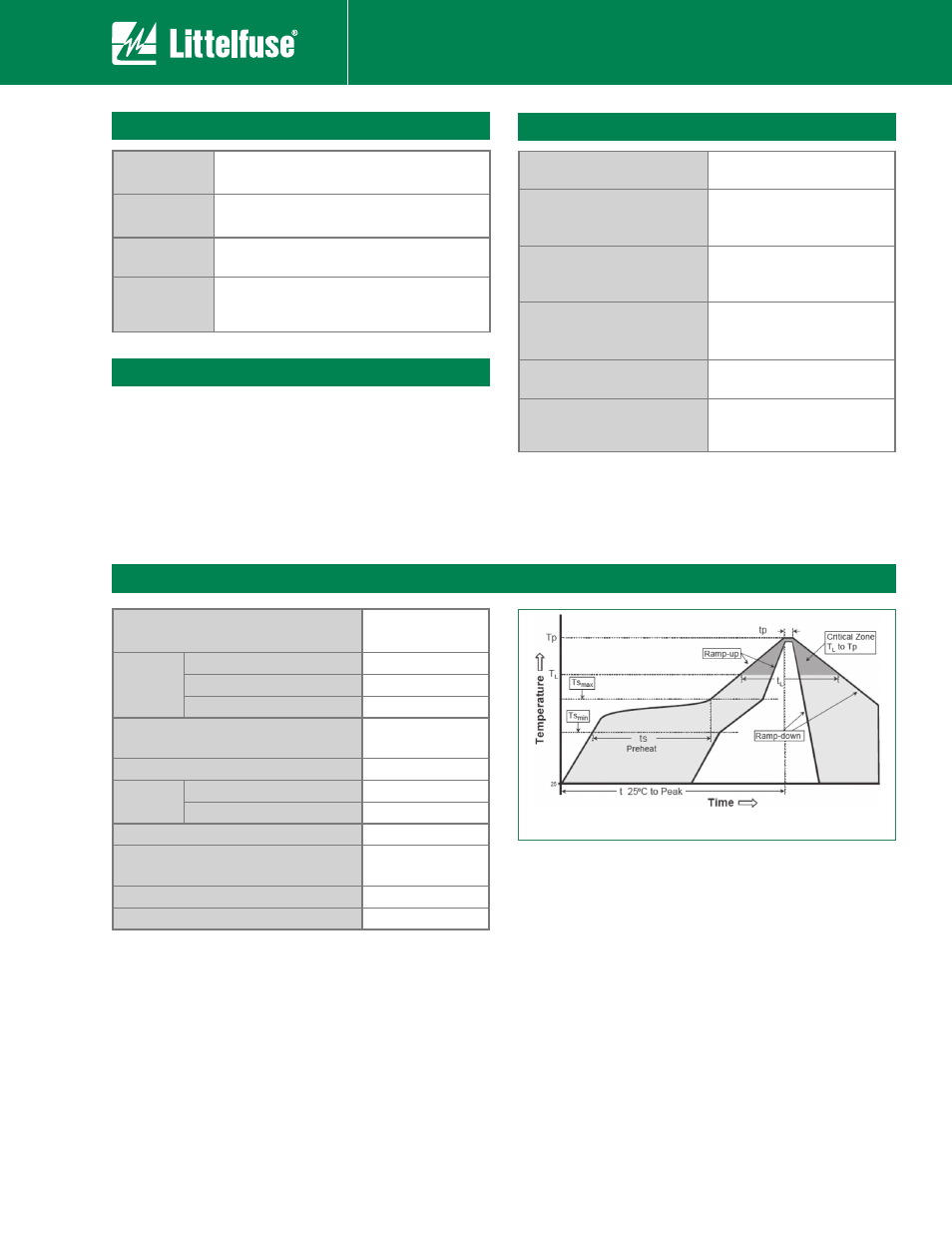

Environmental Specifications

Operating Temperature

-65°C to +125°C

Biased Humity:

Biased Heat:

40°C, 95% RH, 1000 hours

85°C, 1000 hours

Thermal Shock

MIL-STD-202, Method 107G,

-65°C to 125°C, 30 min. cycle,

10 cycles

Vibration

.*-45% .FUIPE"

Chemical Resistance

MIL-STD-202, Method 215

Solder Leach Resistance and

Terminal Adhesion

*1$&*"+45%

Physical Specifications

Materials

#PEZ&QPYZ(MBTT4VCTUSBUF

5FSNJOBUJPOT$V/J4O

Device Weight

0.349 mg

Solderability

MIL-STD-202, Method 208

Soldering

Parameters

8BWFTPMEFS¡$

TFDPOETNBYJNVN

3FnPXTPMEFS¡$

TFDPOETNBYJNVN

Design Consideration

Because of the fast rise-time of the ESD transient, proper

QMBDFNFOUPG1VMTF(VBSETVQQSFTTPSTBSFBLFZEFTJHO

consideration to achieving optimal ESD suppression. The

devices should be placed on the circuit board as close to the

source of the ESD transient as possible. Install PulseGuard

TVQQSFTTPST DPOOFDUFEGSPNTJHOBMEBUBMJOFUPHSPVOE

directly behind the connector so that they are the first board-

level circuit component encountered by the ESD transient.

Soldering Parameters

Reflow Condition

Pb – Free assembly

Pre Heat

- Temperature Min (T

s(min)

)

150°C

- Temperature Max (T

s(max)

)

200°C

- Time (min to max) (t

s

)

60 – 180 seconds

Average ramp up rate (Liquidus Temp

(T

L

) to peak

¡$TFDPOENBY

T

S(max)

to T

L

- Ramp-up Rate

¡$TFDPOENBY

Reflow

- Temperature (T

L

) (Liquidus)

217°C

- Temperature (t

L

)

60 – 150 seconds

Peak Temperature (T

P

)

260°C

Time within 5°C of actual peak

Temperature (t

p

)

10 – 30 seconds

Ramp-down Rate

¡$TFDPOENBY

Time 25°C to peak Temperature (T

P

)

NJOVUFTNBY

Notes:

- PGB2 Series recommended for reflow soldering only

3FDPNNFOEFEQSPmMFCBTFEPO*1$+&%&%+45%$

- For recommended soldering pad layout dimensions,

please refer to Dimensions section of this data sheet