Varistor products, Mhs s eries – Littelfuse MHS Varistor Series User Manual

Page 3

© 2013 Littelfuse, Inc.

25

Revised: December 16, 2013

Varistor Products

MHS S

eries

MHS Varistor Series

Surface Mount Multilayer Varistors (MLVs) > MHS Series

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/MHS.html for current information.

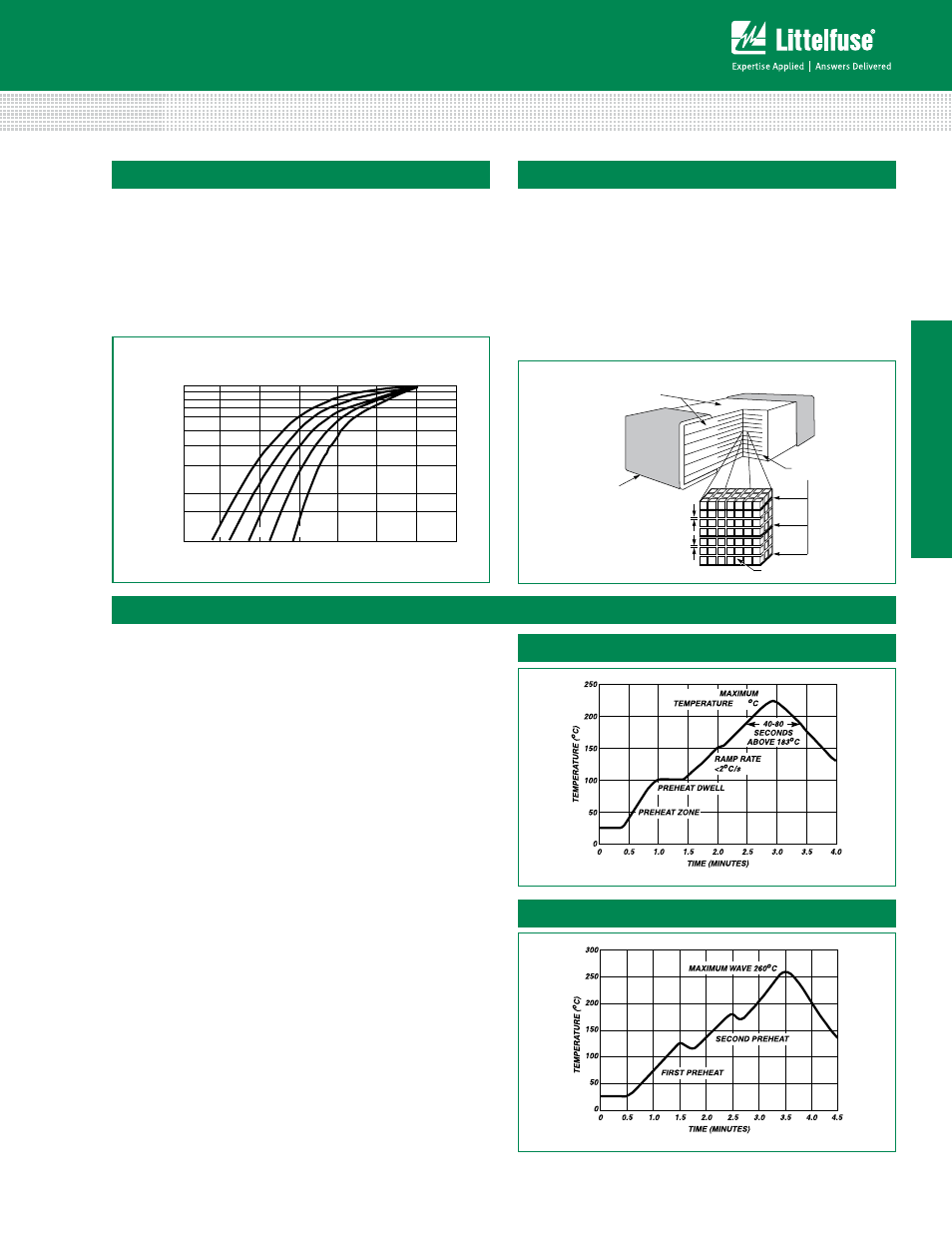

Lead (Pb) Soldering Recommendations

The principal techniques used for the soldering of

components in surface mount technology are IR Re-flow

and Wave soldering. Typical profiles are shown on the right.

The recommended solder for the MHS suppressor is

a 62/36/2 (Sn/Pb/Ag), 60/40 (Sn/Pb) or 63/37 (Sn/Pb).

Littelfuse also recommends an RMA solder flux.

Wave soldering is the most strenuous of the processes.

To avoid the possibility of generating stresses due to

thermal shock, a preheat stage in the soldering process

is recommended, and the peak temperature of the solder

process should be rigidly controlled.

When using a reflow process, care should be taken to

ensure that the MHS chip is not subjected to a thermal

gradient steeper than 4 degrees per second; the ideal

gradient being 2 degrees per second. During the soldering

process, preheating to within 100 degrees of the solder's

peak temperature is essential to minimize thermal shock.

Once the soldering process has been completed, it is

still necessary to ensure that any further thermal shocks

are avoided. One possible cause of thermal shock is hot

printed circuit boards being removed from the solder

process and subjected to cleaning solvents at room

temperature. The boards must be allowed to cool gradually

to less than 50ºC before cleaning.

6.

5.

230

5.0 6.0 7.0

MAXIMUM TEMPERATURE 260˚C

20 - 40 SECONDS WITHIN 5˚C

PREHEAT ZONE

RAMP RATE

<3˚C/s

60 - 150 SEC

> 217˚C

FIGURE 7. LEAD-FREE RE-FLOW PROFILE

6.

5.

230

5.0 6.0 7.0

MAXIMUM TEMPERATURE 260˚C

20 - 40 SECONDS WITHIN 5˚C

PREHEAT ZONE

RAMP RATE

<3˚C/s

60 - 150 SEC

> 217˚C

FIGURE 7. LEAD-FREE RE-FLOW PROFILE

Reflow Solder Profile

Wave Solder Profile

Device Characteristics

At low current levels, the V-I curve of the multilayer

transient voltage suppressor approaches a linear (ohmic)

relationship and shows a temperature dependent effect.

At or below the maximum working voltage, the suppressor

is in a high resistance model (approaching 10

6

Ω at its

maximum rated working voltage). Leakage currents at

maximum rated voltage are below 100µA, typically 25µA;

for 0402 size below 20µA, typically 5µA.

100%

1E

-9

1E

-8

SUPPRESSOR CURRENT (A

DC

)

10%

1E

-7

1E

-6

1E

-5

1E

-4

1E

-3

1E

-2

25

50

75

100

125

o

C

SUPPRESSOR

VO

LT

A

GE IN PERCENT OF

V

NOM

V

ALUE

AT

25

o

C (%)

FIGURE 10. TYPICAL TEMPERATURE DEPENDANCE OF THE CHARACTERISTIC

CURVE IN THE LEAKAGE REGION

o

o

o

o

Typical Temperature Dependance of the Characteristic

Curve in the Leakage Region

Speed of Response

The Multilayer Suppressor is a leadless device. Its response

time is not limited by the parasitic lead inductances found

in other surface mount packages. The response time of the

Z

N

O dielectric material is less than 1ns and the MLE can

clamp very fast dV/dT events such as ESD. Additionally,

in “real world” applications, the associated circuit wiring

is often the greatest factor effecting speed of response.

Therefore, transient suppressor placement within a circuit

can be considered important in certain instances.

GRAINS

DEPLETION

FIRED CERAMIC

DIELECTRIC

REGION

METAL

ELECTRODES

DEPLETION

REGION

METAL END

TERMINATION

FIGURE 11. MULTILAYER INTERNAL CONSTRUCTION

Multilayer Internal Construction

Figure 5

Figure 6

Figure 7

Figure 8