Coupling suspension, 2 coupling suspension – R&M Materials Handling ELECTRIC CHAIN HOISTS LoadMate Chain Hoist TMU Motorized Trolley User Manual

Page 7

LM

TMU I&M MANUAL/EN/06.15.2009

7/38

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2009) R&M Materials Handling, Inc. All rights reserved.

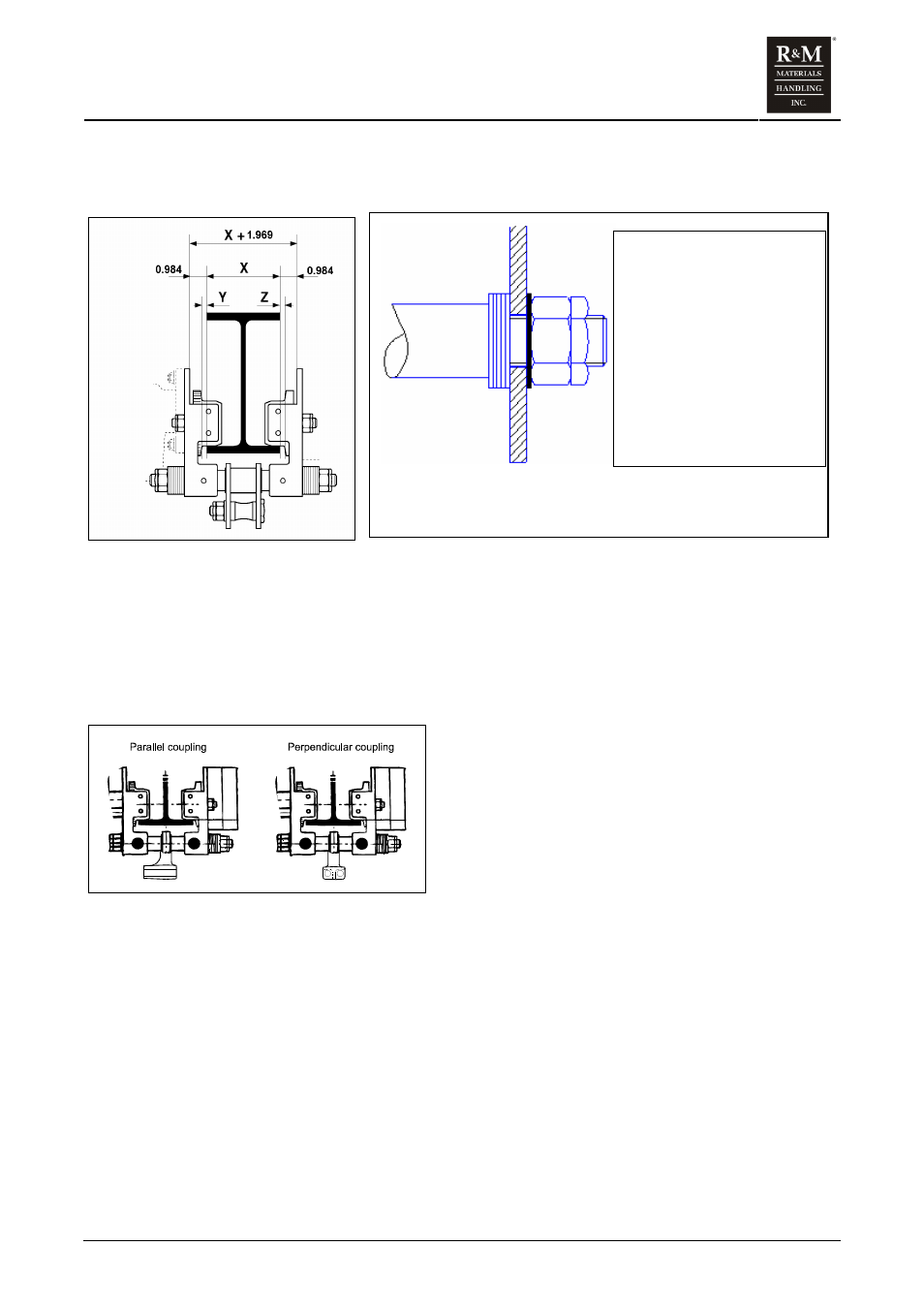

Figure 1. Trolley Installation and Recommended Torque Tensions

Y + Z = 5/32" [4mm] MAX

The total play between wheel flange and the beam flange must not exceed 5/32" [4mm]. The distance

between trolley side plates must be equal to the sum of the beam flange width + 1 15/16" [50mm].

1.2 Coupling

Suspension

Figure 2. Parallel and Perpendicular Coupling Suspensions

When setting the hoist in position, check that the suspension hook or coupling is correctly positioned,

depending on whether the chain hoist is a one-fall or two-fall design. This is necessary for proper balance of

hoist when loaded.

In all cases, allow minimum of one washer under each

tension rod nut.

Recommended

Tightening

Torque for tension rod nut

C1 Trolley: 177 ft-lbs

C2 Trolley: 300 ft-lbs

C3 Trolley: 545 ft-lbs

C5 Trolley: 545 ft-lbs

C1 Trolley: 240 N m

C2 Trolley: 410 N m

C3 Trolley: 740 N m

C5 Trolley: 740 N m