Adjustment of compact brake air gap, Removal and inspection of the brake, Compact brake – R&M Materials Handling ELECTRIC CHAIN HOISTS LoadMate Chain Hoist TMU Motorized Trolley User Manual

Page 19: D.c. disc brake, 8 adjustment of compact brake air gap, 9 removal and inspection of the brake

LM

TMU I&M MANUAL/EN/06.15.2009

19/38

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2009) R&M Materials Handling, Inc. All rights reserved.

3.8 Adjustment of Compact Brake Air Gap

y

Disconnect power and lockout disconnecting means on the crane/hoist.

y

Disconnect the power cable plug from the hoist.

y

Remove brake and motor leads from enclosure.

y

Remove the brake cover.

y

Push the brake disk and measure the air gap between the adjustment nut and aluminum ring. The air

gap must be 0.008 – 0.012 inches [0.2 - 0.3 mm]. Turn the adjustment nut, to adjust the air gap.

y

Add the brake cover, install brake and motor leads, and connect the power supply plug to motor.

3.9 Removal and Inspection of the Brake

3.9.1 Compact

Brake

y

Disconnect power and lockout disconnecting means on the crane/hoist.

y

Disconnect the power cable plug from the hoist.

y

Remove the brake cover.

y

Unscrew and remove the adjustment nut.

y

Remove the brake parts. If the thickness of the friction disc is less than 0.197” [5 mm], replace brake

discs and friction disc.

y

Re-assemble in the reverse order.

y

Adjust the brake air gap.

3.9.2 D.C. Disc Brake

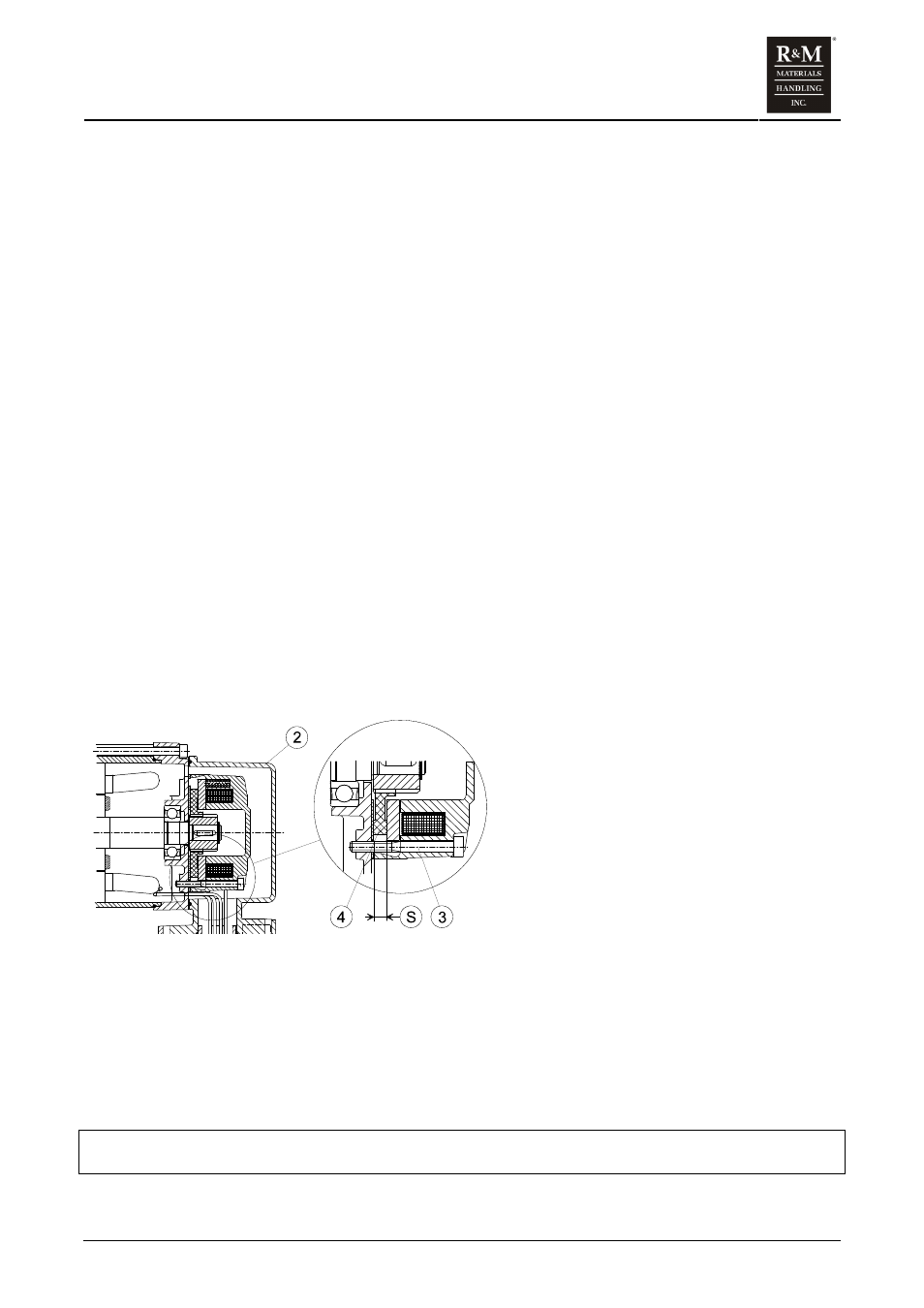

Figure 8. D.C. Disc Brake and Parts List

y

Disconnect power and lockout disconnecting means on the crane/hoist.

y

Disconnect the power cable plug from the hoist.

y

Remove the brake cover.

y

Unscrew the mounting screws.

y

Remove the brake. If the thickness of the friction disc is less than 0.23” [5.8 mm], replace brake discs

and friction disc.

y

Re-assemble in the reverse order.

y

Recommended tightening torque for mounting screws is 1.8 lb-ft [2.5 Nm]

)

Note: The air gap on the D.C. Brake is not adjustable.

2. Brake cover

3. Mounting screws

4. Friction disc

S. Thickness of friction disc

Data below is for NM38710NR#, 2

Nm brake type and torque size