Technical characteristics, Normal operation for trolley, Led status indicator – R&M Materials Handling ELECTRIC CHAIN HOISTS LoadMate Chain Hoist TMU Motorized Trolley User Manual

Page 23

LM

TMU I&M MANUAL/EN/06.15.2009

23/38

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2009) R&M Materials Handling, Inc. All rights reserved.

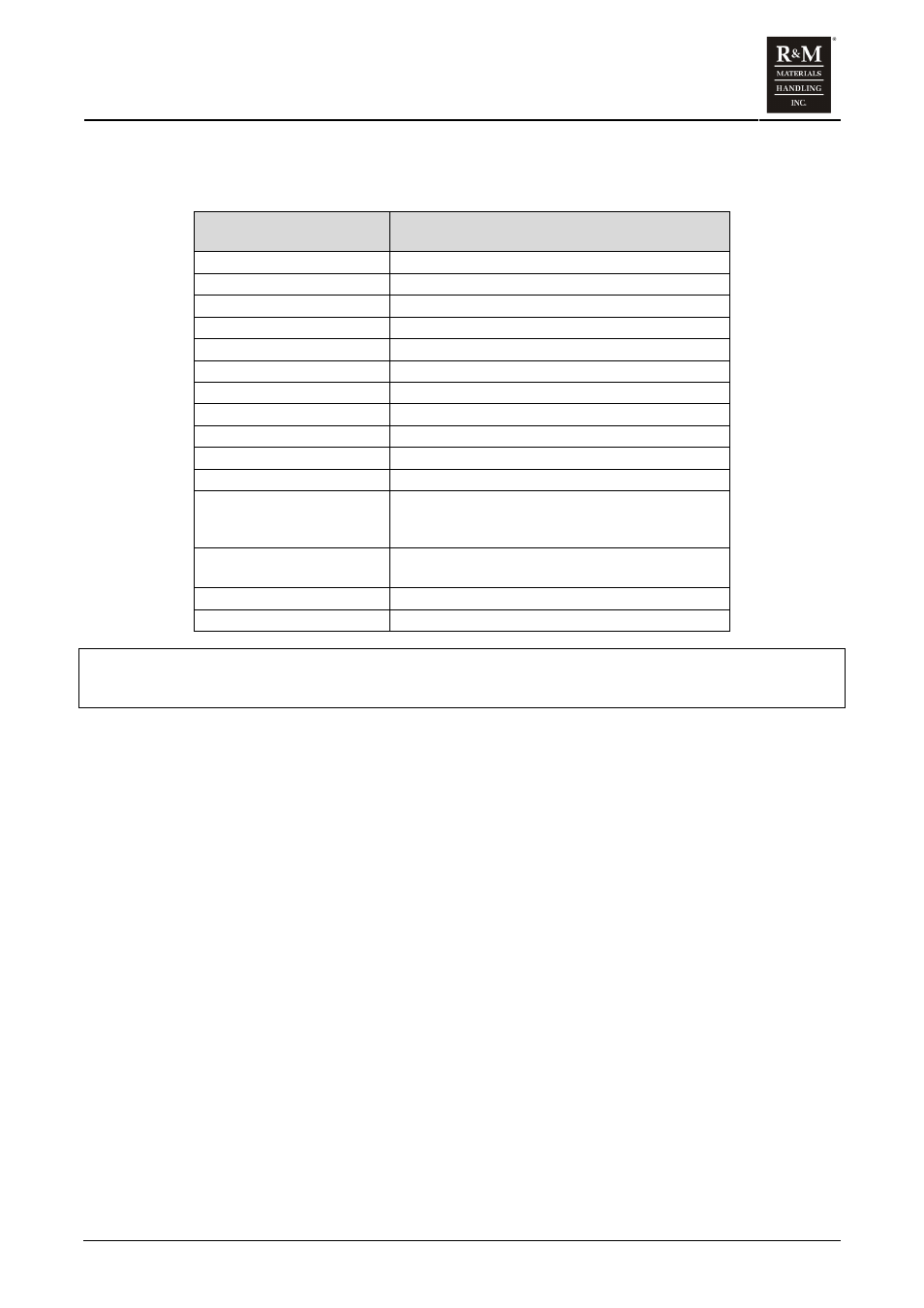

Technical Characteristics

Table 6. Technical Characteristics

Technical

Characteristics

Description

Power range

0.75 kW

Supply voltage*

380 – 480 VAC ±10%

Nominal supply frequency 48 – 62 Hz

Nominal current

2.4 A

Digital control

S1, S2, DI3

Max output voltage

Equal to supply voltage

Control voltage range

48 or 115 VAC ±10%

Ambient temperature

-10

o

C to 50

o

C 14

o

F to 120

o

F

Humidity

95% N. C. (with dripping)

Degree of protection

Inverter + inverter cover IP20

Dimensions (W x H x D)

5.24 x 3.62 x 2.36 in. [133 x 92 x 60 mm]

Altitude

Output current must be reduced 1% for every

100 m over 1000 m. For heights over 3000 m,

consult factory.

Pollution degree

Pollution degree 2 according to NEMA ICS-1,

IEC664 and UL840

Vibration IEC68-2-6

Shock IEC68-2-27

)

Note: * A transformer is used to provide the proper supply voltage if the main power supply is different from the

required supply voltage.

4.1.2 Normal Operation for Trolley

The inverter goes into Ready-to-Run within one second after power is applied to the inverter. During running,

the inverter follows the user defined speed control mode.

The default speed control mode is the two-speed (MS-2).

The stopping method, which the user cannot change on TMU VFD, is programmed to decelerate to a stop

using dynamic braking. As a result of this, the brake is used essentially as a holding brake and the wear on

the brake is minimized. When the RUN Forward/Reverse command is removed, the inverter decelerates to

zero according to its preset ramp time and then the brake sets. If a failure occurs or if the emergency stop

button is pushed, dynamic braking is overridden and the brake closes immediately, bringing the motor and

load to an immediate stop.

4.1.3 LED Status Indicator

TMU VFD indicates its operating status by two LEDs. A steady green LED indicates Ready-to-Run. A

blinking green LED indicates that a fault condition had been activated, but the fault has since recovered.

Normal operation is possible when the green LED is blinking. A blinking red LED indicates a severe fault

condition and operation is inhibited. The blinking pattern tells the user the type of fault that has occurred.