Preventative maintenance, Maintenance table, Lubricants – R&M Materials Handling ELECTRIC CHAIN HOISTS LoadMate Chain Hoist TMU Motorized Trolley User Manual

Page 33: Spare part replacement, Discarding the trolley, 5 preventative maintenance, 1 maintenance table, 2 lubricants, 3 spare part replacement, 4 discarding the trolley

LM

TMU I&M MANUAL/EN/06.15.2009

33/38

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2009) R&M Materials Handling, Inc. All rights reserved.

5 PREVENTATIVE

MAINTENANCE

The service life of the TMU depends on the demands placed on it such as the average operating time, and

the number of start/stops and its maintenance.

5.1 Maintenance

table

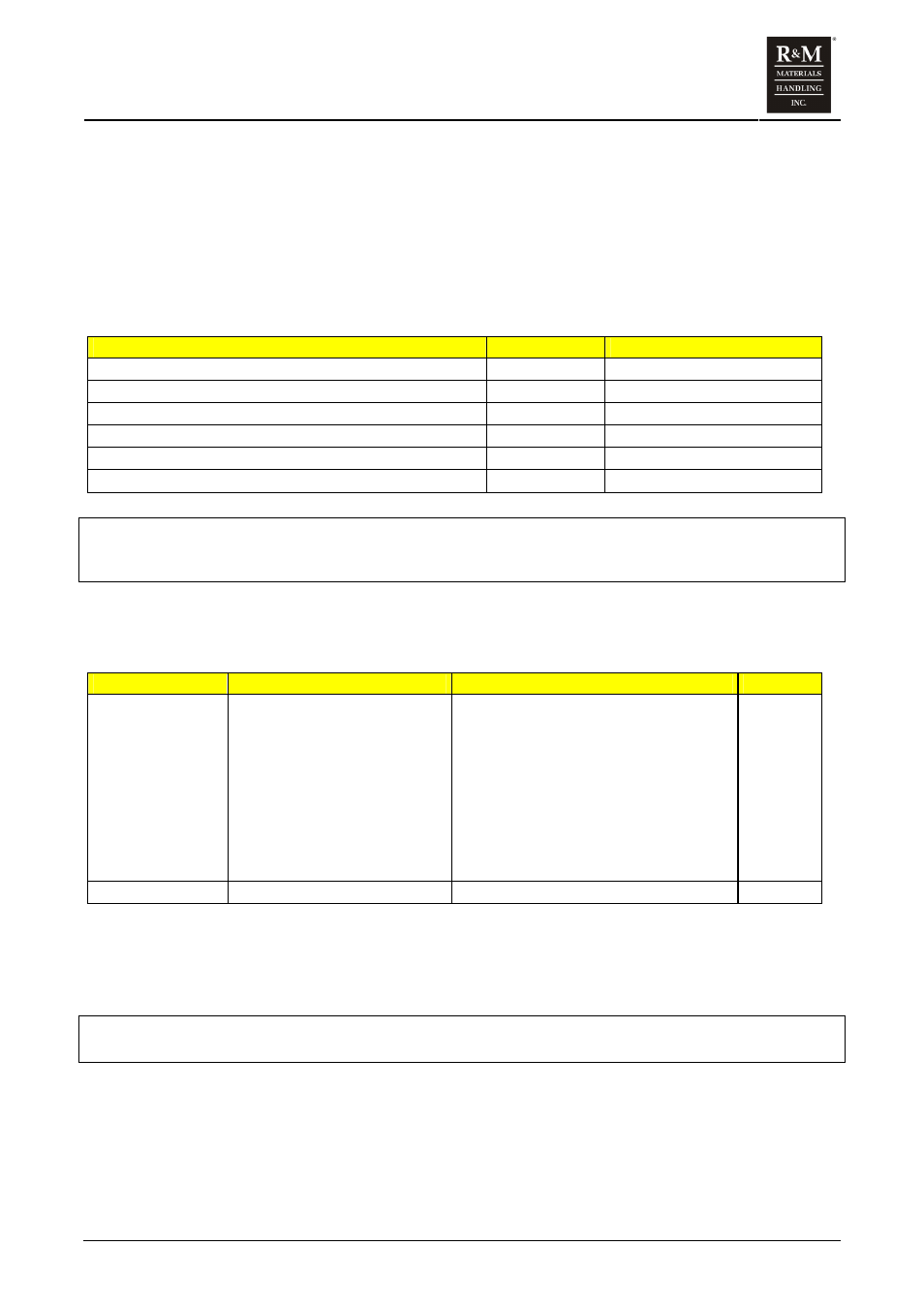

Table 14. Maintenance Schedule

Check

Interval

Qualification of personnel

Brake operation

Daily

Operator

For loose screws and signs of corrosion Annually

Qualified

mechanic

Condition of the brake air gap

Quarterly

Qualified mechanic

Condition of the drive pinion Annually

Operator

Measurement of the wheel tread diameter Annually

Operator

Lubrication of open gear

Quarterly

Operator

m

CAUTION:

These intervals should be shortened if TMU is used daily for eight hours in 24 hour

period, if it is used with maximum loads or in difficult ambient conditions.

5.2 Lubricants

Table 15. Lubricant Specifications

Lubrication point Specifications

Possible brands

Quantity

Roller drive pinion

Bearing (*)

KP 0 K grease (DIN 51502)

Soap-based lithium + MoS 2

Approx. melting point + 356°F

Worked penetration 671 -

725°F

Operating temperature

- 22°F to + 266°F

Tribol: Molub Alloy multi-purpose

grease

Aral: Aral P 64037 grease Aralub PMD0

BP: Multi-purpose grease L 21 M

Esso: Multi-purpose grease M

Mobil: Mobilgrease Special

Shell: Shell Retimax AM

Texaco: Molytex grease EP 2

Fuchs: Renolit FLM0

As

necessary

(*) 0.02 L

Gear reducer

Mobilux EP00

5.3 Spare Part Replacement

After a long period of non-use or during a routine check, check the operation and adjustment of the safety

items (brake, end stops...). If there is a possibly defective element, deformation or abnormal wear, the parts

must be changed.

m

CAUTION: Disconnect the power supply before replacing any parts.

If a part has been replaced, check the operation of the equipment before the equipment is returned to service.

5.4 Discarding the Trolley

Remove all grease from the trolley and gear reducer before discarding the unit to the recycle center.