B&B Electronics ZXT9-IO-222R2 - Quick Start Guide User Manual

Page 3

pn 8590R1-ZXTx-IO-x-2011QSG –Peer-to-Peer Mode

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF ANY

COMPONENT MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2.

WARNING – EXPLOSION HAZARD – WHEN IN HAZARDOUS

LOCATIONS, TURN OFF POWER BEFORE REPLACING

ANTENNA.

Intended use of equipment – please see the B&B Electronics

Data Sheets and Quick Start Guides for each Zlinx Xtreme

product for explanations of the intended use of this equipment.

Wiring Terminals – Use Copper Wire Only, one conductor per

terminal

Wire Range 30 – 12 AWG

Maximum Surrounding Ambient Air Temperature - 74°C

UL Class I, Division 2 wiring methods. The Zlinx Xtreme

enclosure is provided with two conduit knockouts that serve as

wiring provisions for Class I, Division 2 wiring methods per the

National Electrical Code (NEC).

The following instructions include procedures to be followed in

order to ensure UL "separation between circuits" as defined in

the NEC.

The low-voltage (LV) wiring – DC power, analog & digital signals

– must be separated from the high voltage (HV) wiring for the

relay contacts. In all cases HV wiring must be rated minimum

250V.

Separation between circuits can be accomplished by using one

of the three following methods:

a. Use one conduit knockout to route LV wiring and the

second conduit knockout to route the HV wiring, OR

see methods 2 and 3 below.

The remaining two methods use one conduit

knockout for all wiring. In this case a UL Recognized

(UL type QCRV2) conduit plug must be used per the

NEC to plug the second conduit knockout.

b. Enclose LV wiring in a 250V rated insulated sheath

to separate it from the HV wiring, OR

c. Use 250vac rated wires for both LV and HV wiring.

Temperature rating of field installed conductors - Field

conductors shall be rated 60C/75C minimum (either are

acceptable) and sized accordingly.

When conduit openings are not being used, a UL Recognized

plug (type QCRV2) shall be used.

The following is UL-required information regarding the Sealed

Relay Devices:

WARNING – Exposure to some chemicals may degrade the

sealing properties of materials used in the Sealed Relay Device.

RECOMMENDATION – It is recommended to inspect the

sealed relay device periodically and to check for any

degradation of the materials and to replace the component

product, not the sealed device, if any degradation is found.

Sealed Relay Device Information:

Sealed Device: Relay Models G6RL-14-ASI-DC5, G6RL-

14-ASI-DC6, G6RL-14-SR-ASI-DC5 or G6RL-14-SR-ASI-

DC6 manufactured by Omron Corp.

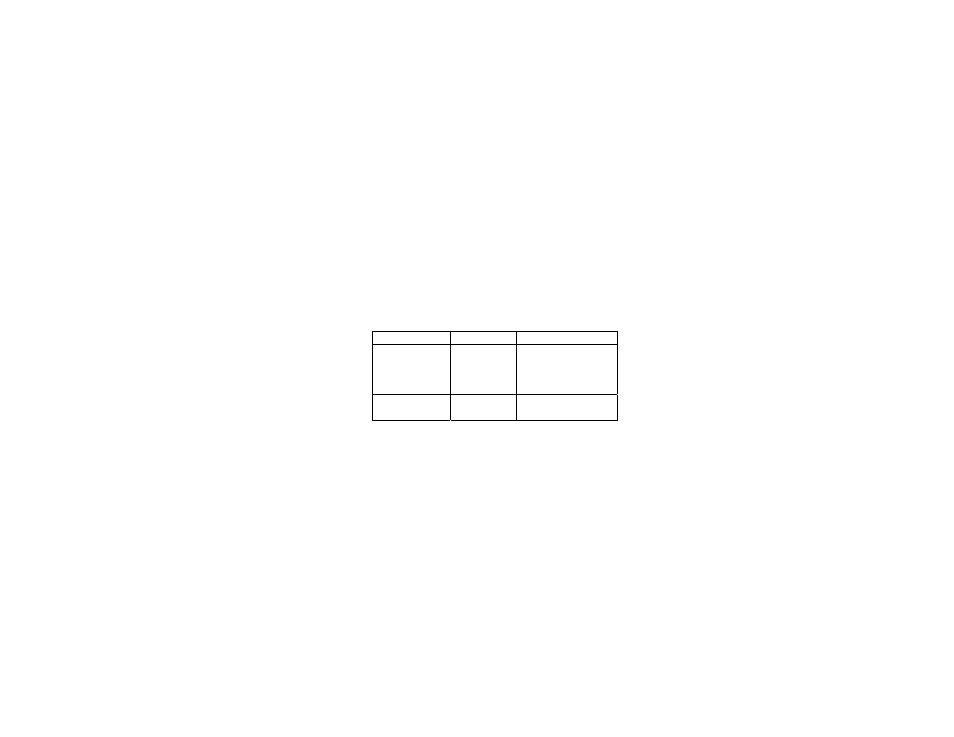

Manufacturer Type

Relay Case and

Base

Mitsubishi

Engineering

Plastics

Corp.

5010GN6-30M8AM

Sealant

Three Bond

Ltd.

TB2225G