Rainbow Electronics MAX1855 User Manual

Page 17

MAX1716/MAX1854/MAX1855

High-Speed, Adjustable, Synchronous Step-Down

Controllers with Integrated Voltage Positioning

______________________________________________________________________________________

17

switching frequency. The on-time guaranteed in the

Electrical Characteristics table is influenced by switch-

ing delays in the external high-side MOSFET. Resistive

losses—including the inductor, both MOSFETs, output

capacitor ESR, and PC board copper losses in the out-

put and ground—tend to raise the switching frequency

at higher output currents. Switch dead-time can

increase the effective on-time, reducing the switching

frequency. This effect occurs only in PWM mode (SKIP

= high) when the inductor current reverses at light or

negative load currents. With reversed inductor current,

the inductor’s EMF causes LX to go high earlier than

normal, extending the on-time by a period equal to the

DH-rising dead-time.

When the controller operates in continuous mode, the

dead-time is no longer a factor and the actual switching

frequency is:

ƒ = (V

OUT

+ V

DROP1

) / [t

ON

× (V+ + V

DROP1

– V

DROP2

)]

where V

DROP1

is the sum of the parasitic voltage drops

in the inductor discharge path, including synchronous

rectifier, inductor, and PC board resistances; V

DROP2

is

the sum of the resistances in the charging path, includ-

ing high-side switch, inductor, and PC board resis-

tances; and t

ON

is the on-time calculated by the

MAX1716/MAX1854/MAX1855.

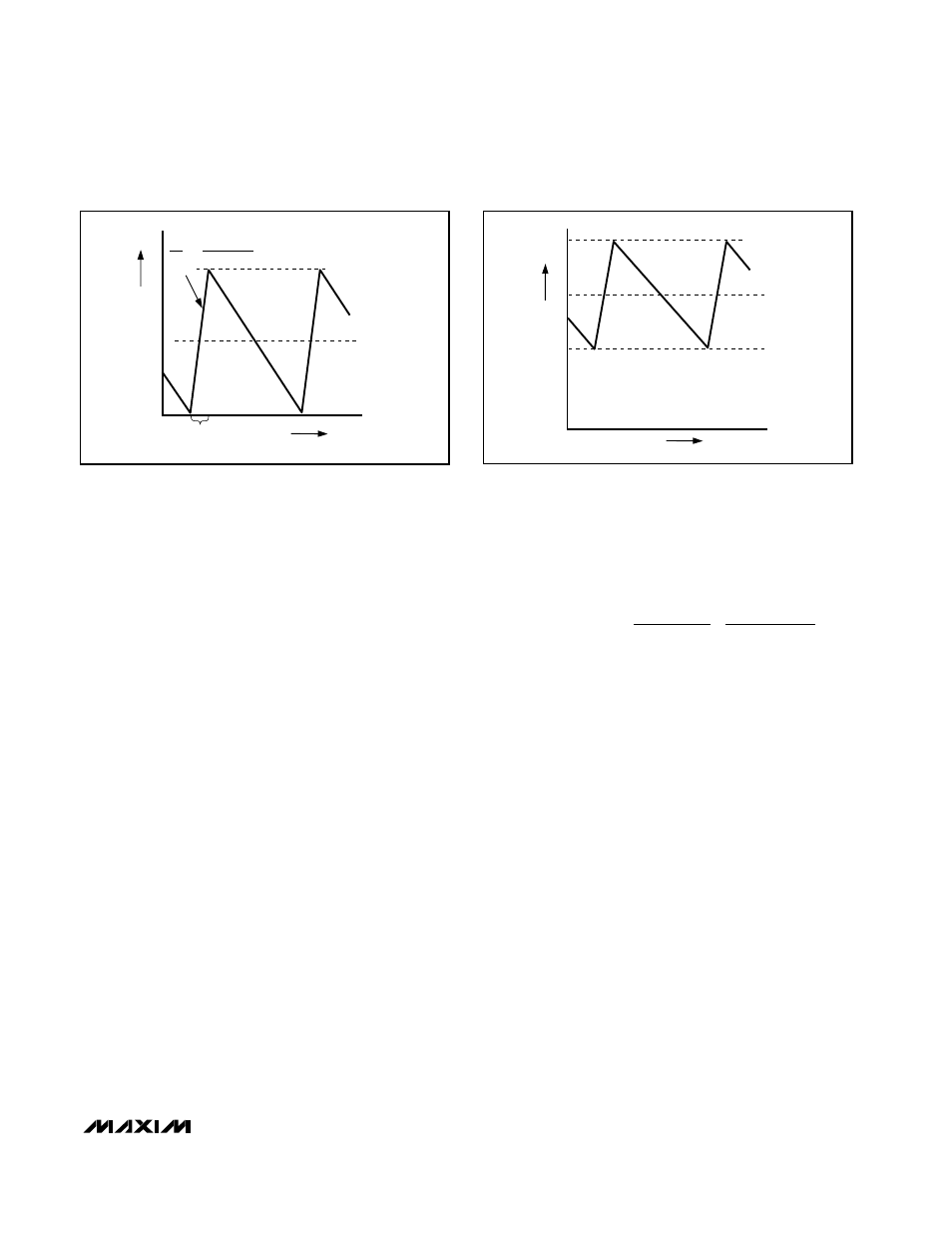

Automatic Pulse-Skipping Switchover

In skip mode (SKIP = low), an inherent automatic

switchover to PFM takes place at light loads (Figure 3).

This switchover is controlled by a comparator that trun-

cates the low-side switch on-time at the inductor cur-

rent’s zero crossing. This mechanism causes the

threshold between pulse-skipping PFM and nonskip-

ping PWM operation to coincide with the boundary

between continuous and discontinuous inductor-cur-

rent operation. For an input voltage (V+) range of 7V to

24V, this threshold is relatively constant, with only a

minor dependence on the input voltage:

where K is the on-time scale factor (Table 3). The load-

current level at which PFM/PWM crossover occurs,

I

LOAD(SKIP)

, is equal to 1/2 the peak-to-peak ripple cur-

rent, which is a function of the inductor value (Figure 3).

For example, in the standard application circuit with

K = 3.3µs (300kHz), V

BATT

= 12V, V

OUT

= 1.6V, and

L = 0.68µH, switchover to pulse-skipping operation

occurs at I

LOAD

= 2.3A or about 1/4 full load. The

crossover point occurs at an even lower value if a

swinging (soft-saturation) inductor is used.

The switching waveforms may appear noisy and asyn-

chronous when light loading causes pulse-skipping

operation; this is a normal operating condition that

improves light-load efficiency. Trade-offs in PFM noise

vs. light-load efficiency are made by varying the induc-

tor value. Generally, low inductor values produce a

broader efficiency vs. load curve, while higher values

result in higher full-load efficiency (assuming that the

coil resistance remains fixed) and less output voltage

ripple. Penalties for using higher inductor values

include larger physical size and degraded load-tran-

sient response (especially at low input voltage levels).

Forced-PWM Mode (

S

SK

KIIP

P

= High)

The low-noise, forced-PWM mode (SKIP driven high)

disables the zero-crossing comparator that controls the

INDUCTOR CURRENT

I

LIMIT

I

LOAD

0

TIME

-I

PEAK

Figure 4. “Valley” Current-Limit Threshold Point

INDUCTOR CURRENT

I

LOAD

= I

PEAK

/2

ON-TIME

0

TIME

-I

PEAK

L

V

BATT

- V

OUT

∆i

∆t

=

Figure 3. Pulse-Skipping/Discontinuous Crossover Point

I

K

V

L

V

V

V

LOAD SKIP

OUT

OUT

(

)

≈

Ч

+ −

+

2