Recommendations for mounting your power-gate60 – Turbosmart WASTEGATES – EXTERNAL - Power-Gate 60 User Manual

Page 2

www.TURBOSMARTONLINE.com

2

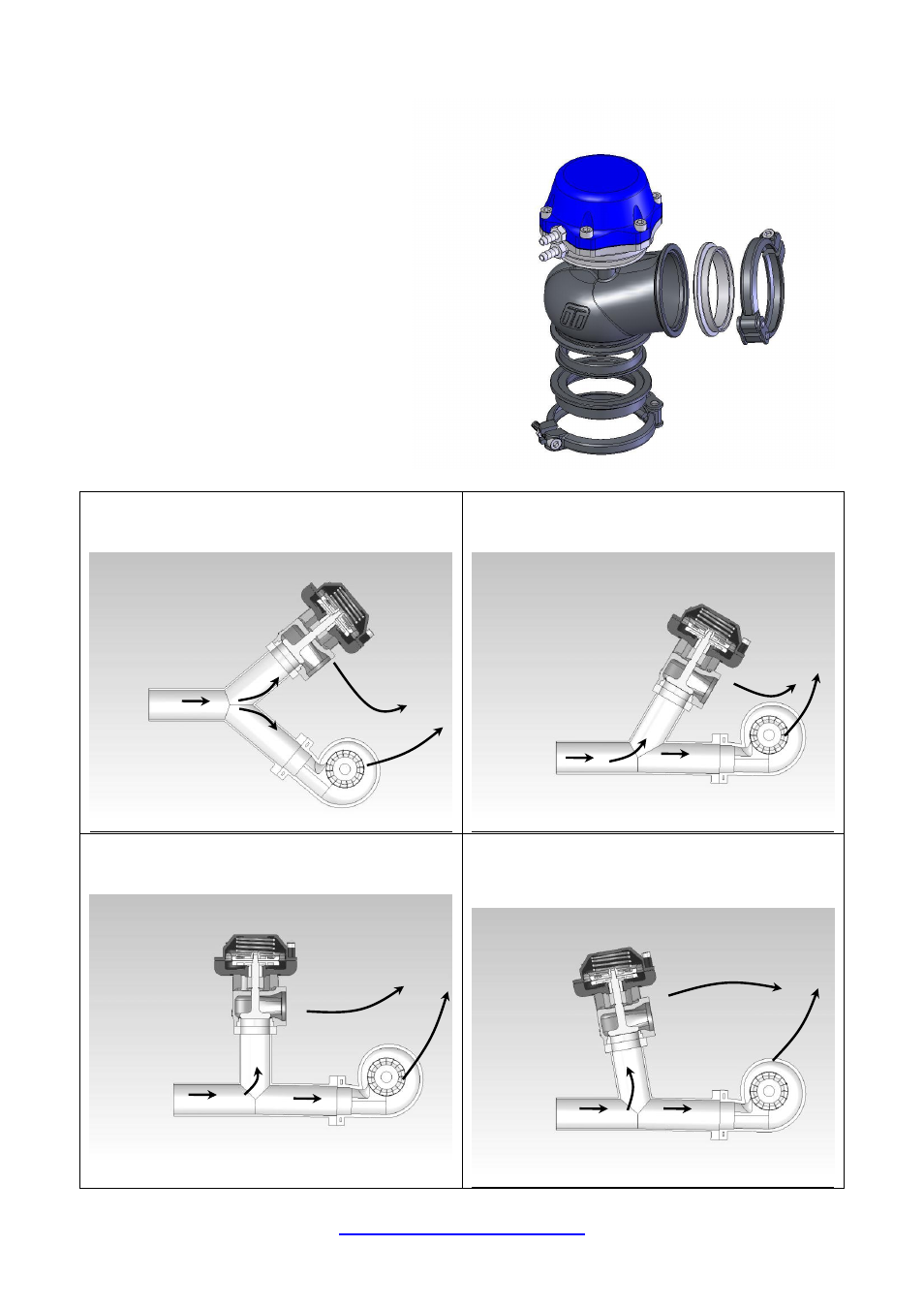

Best Flow

– Symmetric Mounting

Symmetric mounting allows an excellent flow of exhaust to the

Power-Gate60.

Good Flow

– Angled Mounting

Angled mounting allows a good flow of exhaust to the Power-

Gate60.

Poor Flow

– 90 Degree Mounting

90 degree mounting gives poor exhaust flow to the Power-Gate60

and in some circumstances may contribute to over boosting.

Not recommended

– Less than 90 Degree Mounting

An angled mounting as shown is not recommended and gives

extremely poor exhaust flow to the Power-Gate60.

RECOMMENDATIONS FOR MOUNTING YOUR POWER-GATE60

The mounting position of your Power-Gate60 will be largely

determined by your turbo and manifold setup and may be

constrained by space restrictions in your engine bay. The following

points should be considered when mounting your Power-Gate60.

-

The weld flanges should be welded to your exhaust

system. The weld flanges are compatible with Stainless

Steel and Mild steel welding rod material.

-

Secure the Power-gate60 to the weld flanges with the

supplied V-Band clamps. Do not forget to put the valve

seat into the body before mounting the unit on the

exhaust manifold. Tighten the supplied M6 screws to a

torque value of 14 Nm (10 ft/lbs)

-

For best results an attempt should be made if space

allows to mount the Power-Gate60 at an angle to the

exhaust flow to allow for better flow than a 90 degree

mounting. See the schematic diagrams below for

examples of mounting positions.

Exhaust Gas

from manifold

Turbocharger Turbine

Wastegate

Exhaust gas

to exhaust

pipe

Exhaust gas

to exhaust

pipe

Exhaust Gas

from manifold

Wastegate

Turbocharger Turbine

Exhaust gas

to exhaust

pipe

Wastegate

Turbocharger Turbine

Exhaust gas

to exhaust

pipe

Wastegate

Turbocharger Turbine

Exhaust Gas

from manifold

Exhaust Gas

from manifold