Trouble shooting – Turbosmart BLOW OFF VALVES - Big Bubba BPV_BOV – Universal User Manual

Page 2

2

The Big Bubba BPV is preinstalled with a spring which will hold 12 InHg (TS-0204-2202) and is designed to be OPEN at idle. It does

not need to be adjusted if the BOV if being used in a recirculation application or Supercharger application. A 7 InHg spring (TS-0204-

2201) is available if higher valve response is needed or your engine

’s vacuum level is very low.

The Bubba Sonic VTA is preinstalled with a spring which will hold 17 InHg (TS-0204-2203) with the cap at its lowest position and is

designed to be closed at idle. A 21 InHg (TS-0204-2204) spring is available if your engine produces high vacuum and the valve needs

to be closed at idle to prevent unmetered air entering the system.

MAINTENANCE

Turbosmart recommends that the following maintenance procedure is carried out at six monthly intervals or at higher intervals if the

environment is very dusty or wet. Regular maintenance will ensure that your BOV is operating at its peak performance and will extend

the working life of the product.

Remove the cap of the BOV by rotating in an anti-clockwise direction

– CAUTION, the cap is under spring force, remove with

care!

Carefully remove the piston and thoroughly clean the piston and the bore of the BOV

Inspect the surface of the piston and the bore of the BOV for scoring or excessive wear, silver coloured marks on the bore are

an indication of excessive wear

Check the Base O-ring and the Cap O-ring for any damage

– replace if necessary

Lubricate the bore and the piston with Uni-

Glide™, hydraulic oil or sewing machine oil – DO NOT use grease or viscous oils

Re-assemble the BOV in the reverse order

----------------------------------------------------------------------------------------------------------------------

TROUBLE SHOOTING

The following points should be checked if you find that your engine is dipping below normal idle, stalling or if the BOV is functioning

poorly. Please note, the following checks will cure 99% of problems experienced with a BOV.

Check the vacuum hose for splits, cracks, loose connection, kinking or any obstruction

– old or fatigued hose may collapse under

vacuum causing an obstruction

With the engine running remove the vacuum / pressure hose from the nipple in the cap of the BOV, there should a loud hissing

sound. The engine should idle poorly, double check by covering the end of the hose with your finger. If this does not occur, the

hose could be blocked or crimped. Check the hose and replace if necessary.

Ensure that the vacuum / pressure source is not shared and that the vacuum source is directly from the inlet manifold

Check the seal between the adapter and the BOV

– ensure that there is no gap between the BOV base and the weld flange

Check the join between the adapter and the intercooler pipe for leaking

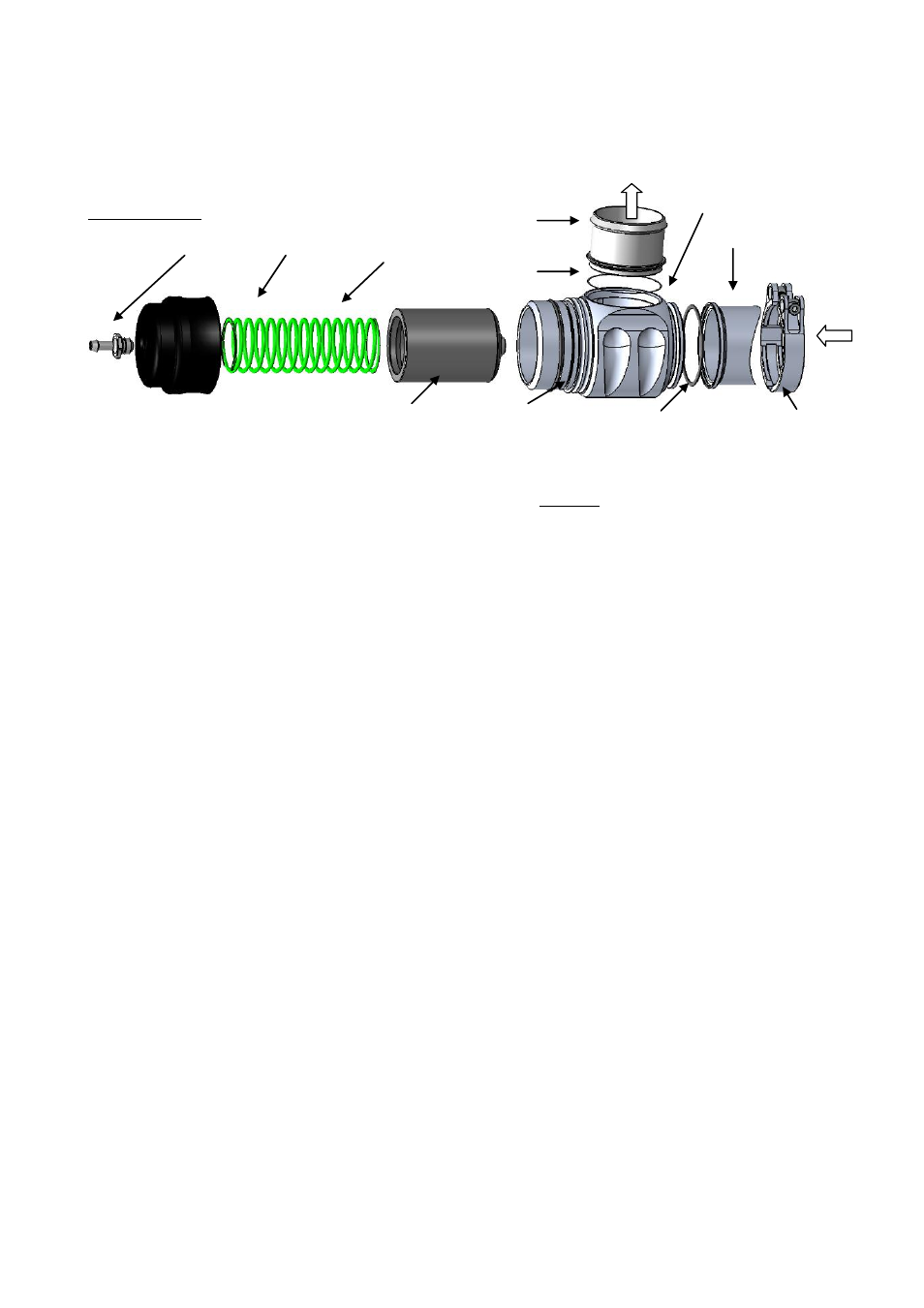

Cap

Swivel Nipple

Spring

Piston

Body

V-Band clamp

O-Ring seal

Weld flange

O-Ring seal

Plumb back fitting

Inlet

Outlet

Indicator O-Ring