Milton CAT G200LG4 200kW_250kVA LG Installation Guide User Manual

Page 11

9

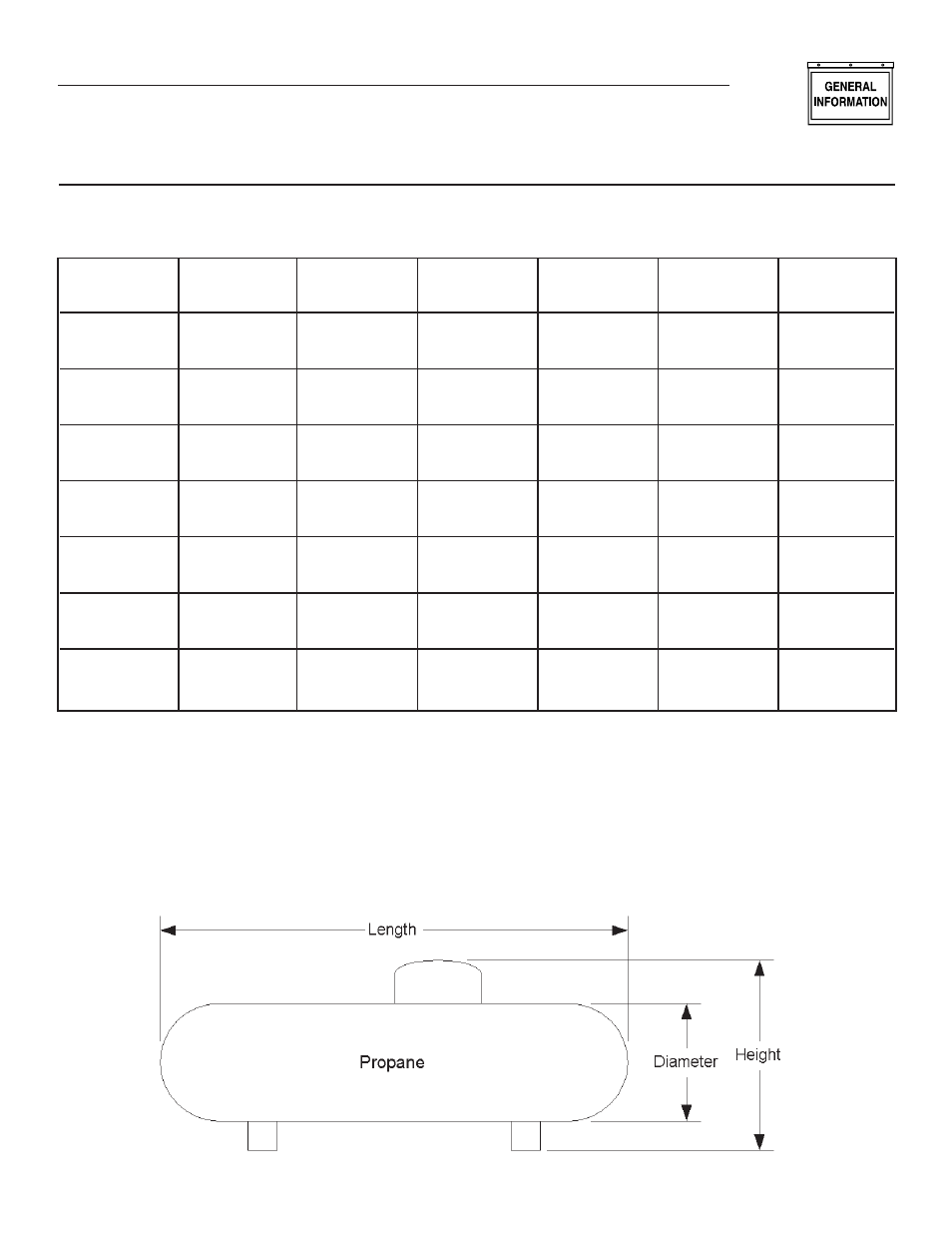

TABLE 1 — VAPOR CAPACITY OF PROPANE STORAGE TANKS

To Use: Go to the First column and pick the required kW load and then pick the minimum ambient temperature

(40º, 20º or 0º F) that the generator would be operating in. The third column (tank capacity) will give the required

tank size to continually produce the given fuel flow.

Propane storage tanks can provide either a liquid or a vapor supply to the generator. The above chart is for vapor

withdrawal only and provides the kW output or amount of vapor that can be withdrawn at a given temperature

while keeping the temperature of the liquid above the boiling point. If the withdrawal rate is too high, the LP tem-

perature goes below the boiling point, the pressure drops to zero and no vapor can be withdrawn. A primary regu-

lator is also required at the tank to reduce the line pressure to the generator to 5-14 inches of water column.

Propane Conversions: 36.38 ft

3

= 90,500 btu = 1 gal • 1lb = 21,500 btu = 8.56 ft

3

Figure 1.6 — Propane Storage Tank

Operating

Max kW

Minimum

Hours @

Tank Capacity

Length

Dia

Overall

Vapor

Temp

Max

kW

(Gallons)

Inches

Inches Ht.

Inches

30

40

24

20 20 35 120 57 24 33

10

0

67

35

40

26

25 20 36 150 68 24 33

12

0

72

60

40

26

40 20 38 250 94 30 39

20

0

74

80

40

26

50 20 40 325 119 30 39

25

0

77

100

40

31

60 20 51 500 119 37 46

30

0

100

150

40

35

100

20

53

850

165

41

50

50

0

105

170

40

36

120

20

51

1000

192

41

50

60

0

103

Section 1 — General Information

Liquid-cooled Generators