Hubcap assembly, Braided hose nut hubcap spindle – Spicer TIMS (Tire Inflation and Monitor System) for Trailers Installation Guide User Manual

Page 19

16

Installation

Installation

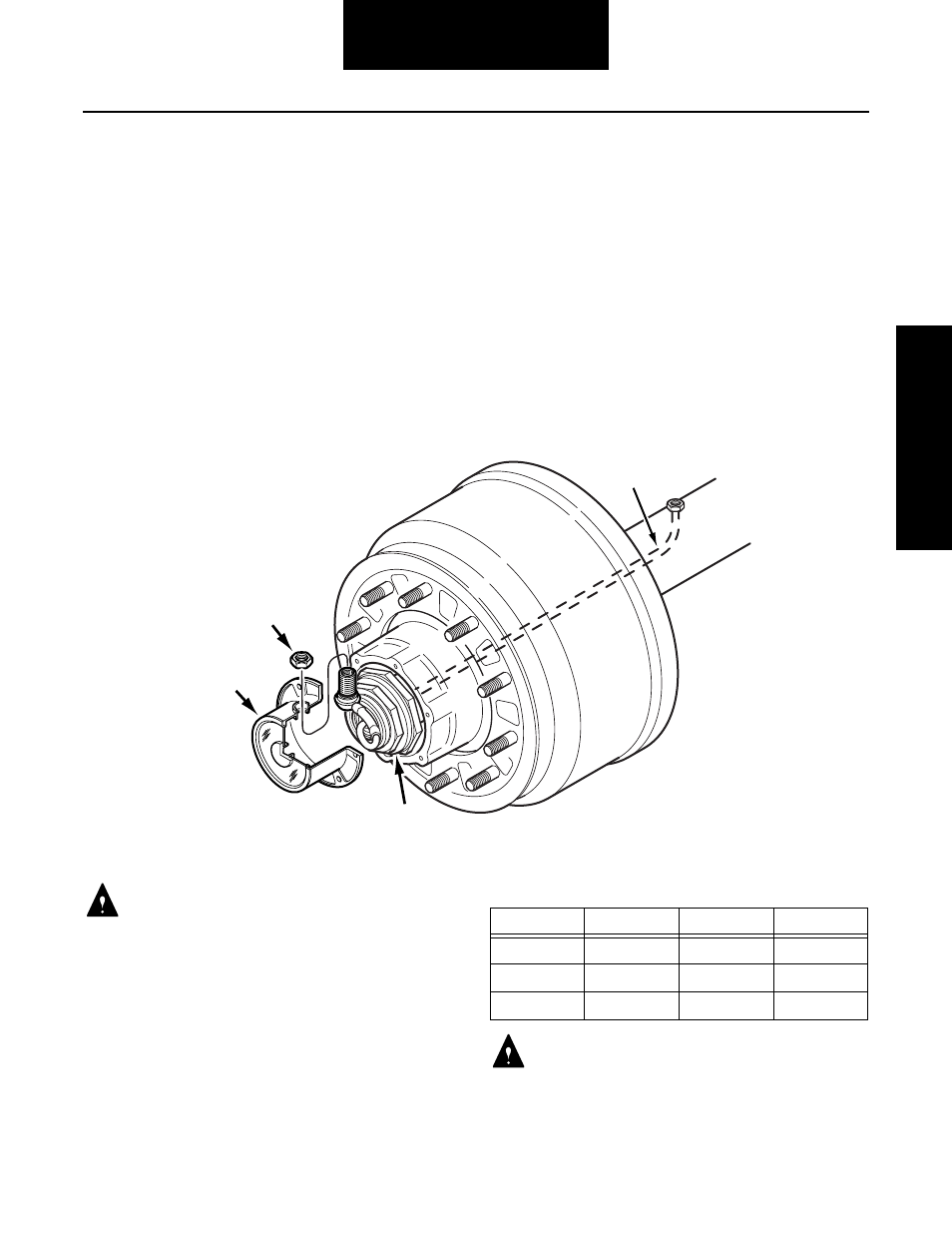

Hubcap Assembly

1.

Place hubcap gasket over rotary joint’s exit tube and

bulkhead adapter.

2.

Lubricate o-ring on the rotary joint’s bulkhead

adapter.

3.

From the inside, insert the bulkhead adapter through

the hole in the hubcap marked “Air.” Be sure to align

the flat on the bulkhead adapter to the flat inside the

hubcap. Attach the jam nut and hand tighten. When

properly seated, the top of the bulkhead adapter will

be flush with the top of the jam nut.

CAUTION: If wheels are installed, refer to Tire Hose In-

stallation on page 24 and Configuration, Clocking, and

Tire Hose Selection Chart on page 25 to determine cor-

rect “clocking” of hubcap. Wheel must be properly “clocked”

to hubcap to prevent hoses rubbing on the wheel. Failure to

properly “clock” hubcap may result in hose failure.

4.

Align the hubcap and gasket and install the 6 bolts.

Torque to the values listed in the Torque Values Chart

per manufacturers recommendations.

5.

Torque the rotary joint's jam nut to 10-12 lbs. ft.

6.

Install lubricant in wheel end to the correct level.

Torque Values Chart

CAUTION: Use of Pro-Torque spindle nuts may require

a hubcap spacer to prevent interference.

218UX014

Braided

Hose

Nut

Hubcap

Spindle

Hub Material

Bolt Grade

Bolt Size

Torque

Iron

5

5/16-18

16-19 lbs. ft.

Iron

8

5/16-18

22-27 lbs. ft.

Aluminum

5 & 8

5/16-18

10-12 lbs. ft.