Introduction, Electrical operation, Electric shift system – Spicer Drive Axles Service Manual Axle Shift Systems, 2-Speed Single Rear Axles User Manual

Page 4

1

Electric Shift System

Introduction

The service procedures and specifications in this publication

cover the current Spicer 2-Speed Axle Shift Systems.

Maintenance and overhaul instructions for the Spicer 2-Speed

Axle carriers are covered in the publications listed on the back

cover.

This manual includes information on two types of Shift Sys-

tems currently in use for Spicer 2-Speed Axles; Electric and

Air.

Spicer 2-Speed Axles are driver-controlled by means of a shift

unit operated from the vehicle cab. These shift units are acti-

vated by air or electric power depending on the convenient

source in the chassis.

Because of this variation, this publication is divided into two

major segments: Electric Shift System for hydraulic-brake

chassis and Air Shift System for air-brake chassis.

Electrical Operation

Note: For component identification and wiring schematic,

refer to illustrations on pages 1, 2, 3, and 4.

Unit in Low Range Shifting to High Range

Current flows through upper contact of control switch, closed

contacts of high-range switch, and motor to ground which

starts the motor rotating. Current also continues from com-

mon motor terminal through low-range switch and to ground

through the resistor.

When motor starts, rotation of the gear allows cam ramp to

apply pressure on low-range cam pin, which allows low range

switch to open. The path to ground (through resistor) is open

and the diode prevents speedometer adapter solenoid from

being energized.

Motor rotation continues to shift axle to high range. As shift is

completed, cam ramp of gear releases high-speed cam pin to

open high-range switch and creates an open circuit to turn off

power to motor. Motor rotation is stopped quickly by means

of dynamic braking through resistor.

If, during rotation, driver decides to switch back to low range,

motor continues to turn.

Opening of high-range switch has no effect since motor is

now being powered by the circuit from control switch,

through diode and low-range switch to ground at motor. In

this instance, motor continues to turn until cam pin opens

low-range switch to turn off power to motor.

Unit in High Range Shifting to Low Range

Current flows through control switch lower contact to ener-

gize speedometer adapter solenoid and through the diode and

low-range switch to common motor terminal and ground at

motor. Motor starts rotating. Current also flows through

closed contact of high-range switch and to ground through

resistor. Once gear rotates enough to apply cam pin pressure

on the high switch, circuit to ground through resistor is open.

As motor rotation continues to shift axle to low range, gear

rotates and releases cam pin on low-range switch to open

switch and open motor circuit. Motor power is turned off.

Once again, the resistor portion of the circuit provides braking

to stop motor quickly.

If, during motor rotation, driver decides to shift back to high

range, the motor continues to turn. Opening of low-range

switch has no effect since motor is now being powered

through control switch. In this instance, motor continues to

turn until gear rotation opens high-range switch to open

motor circuit.

The shift unit always remains synchronized with position of

driver's control switch.

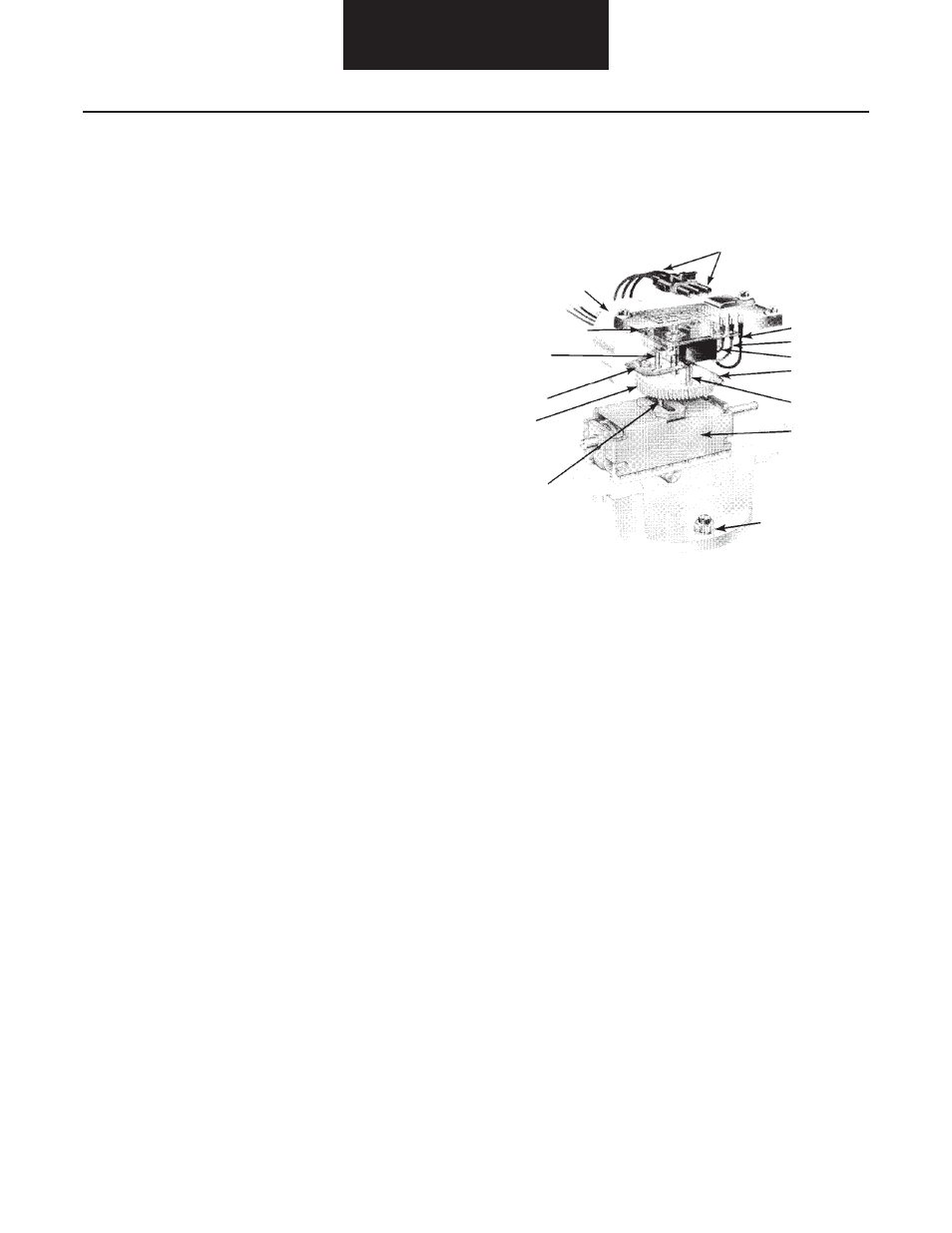

ELECTRIC SHIFT UNIT CUTAWAY

Wiring Harness

and Connector

Black Wire

Green Wire

Red Wire

Worm Gear

Cam Pin

(High Range)

Slider

Block

Flat Washer

(0.100",

2.54 mm

thick)

Gear Pin

(Eccentric)

Gear

Switch

Spring

Cam Pin

(Low Range)

Circuit Board

Assembly

Motor