Replace seal – Spicer Tandem Drive Axles Service Manual D170, D190, and D590 Series User Manual

Page 68

64

Seal - Replace

Replace Seal

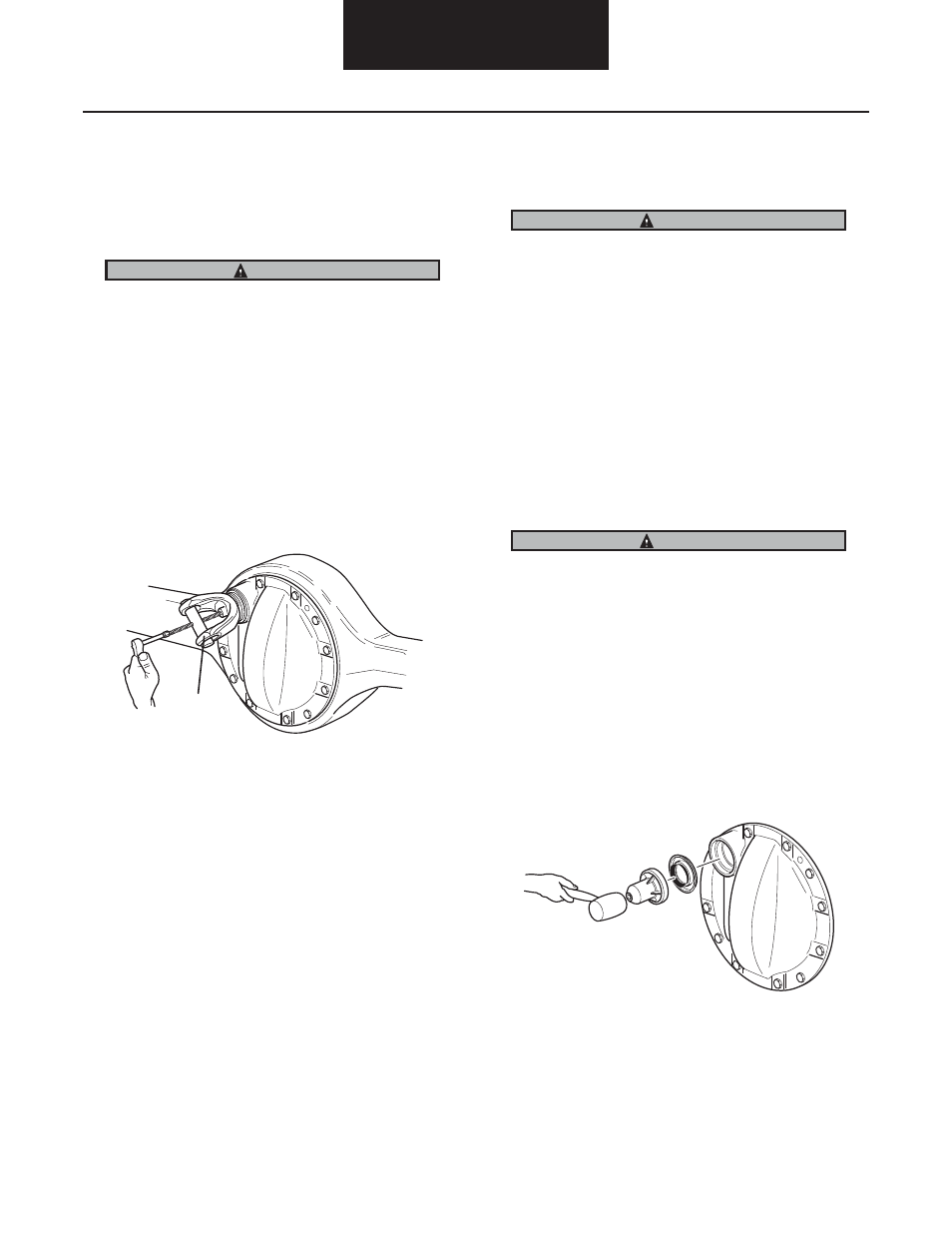

Spicer strongly recommends using seal drivers when installing

new seals. Use the proper driver to make sure that the seal is

square and installed to the proper depth.

Oil seals can be easily damaged prior to installation. Use

care when handling the new seal to prevent damage or con-

tamination. Leave the seal in its package until installation.

On new yokes, leave the protector on the yoke until it is

installed on the shaft to prevent damage or contamination.

1. Inspect axle endplay at the yoke (see page 10). Service

if beyond specified limit.

2. Remove the old yoke using appropriate tool. A yoke

puller tool may be made from the center section of

most gear puller tools, or may be purchased from

your local tool distributor.

Due to the resiliency of the plastic driver, hammer rebound

may occur when the seal is seated. Keep clear of the hammer

rebound path!

6. Handle the seal by its outside diameter avoiding any

contact with the seal lips. During installation, use the

proper driver to make sure that the seal is mounted

properly.

7. Use a rubber mallet to drive the seal tool in until the

flange bottoms on the housing cover bore face. The

flange will locate the seal at the proper depth.

Do not use any silicone or permatex-type bore sealant with

this seal.

5. Remove the new seal from its package and install

with the proper driver:

D - Input Driver - 210749

D - Input Insert - 131472

D - Output Driver - 131471

R - Pinion Driver - 210749

R - Pinion Insert - 131472

3. Remove seal. Use care when removing the old seal

to prevent damage to the housing seal bore.

4. Inspect the seal bore area for any damage (nicks,

gouges, corrosion). Carefully remove any slight

damage with a crocus cloth. Clean the bore area to

remove any loose debris.

CAUTION

1

CAUTION

WARNING

1 - Yoke Puller Tool