Drive pinion – Spicer Tandem Drive Axles Service Manual D170, D190, and D590 Series User Manual

Page 33

29

Drive Pinion

Use the correctly sized spacer. Do not use shim stock or

grind spacers. These practices can lead to loss of bearing

preload and gear or bearing failure.

To prevent bearing damage, use suitable sleeve that only

contacts the inner race of bearing cone.

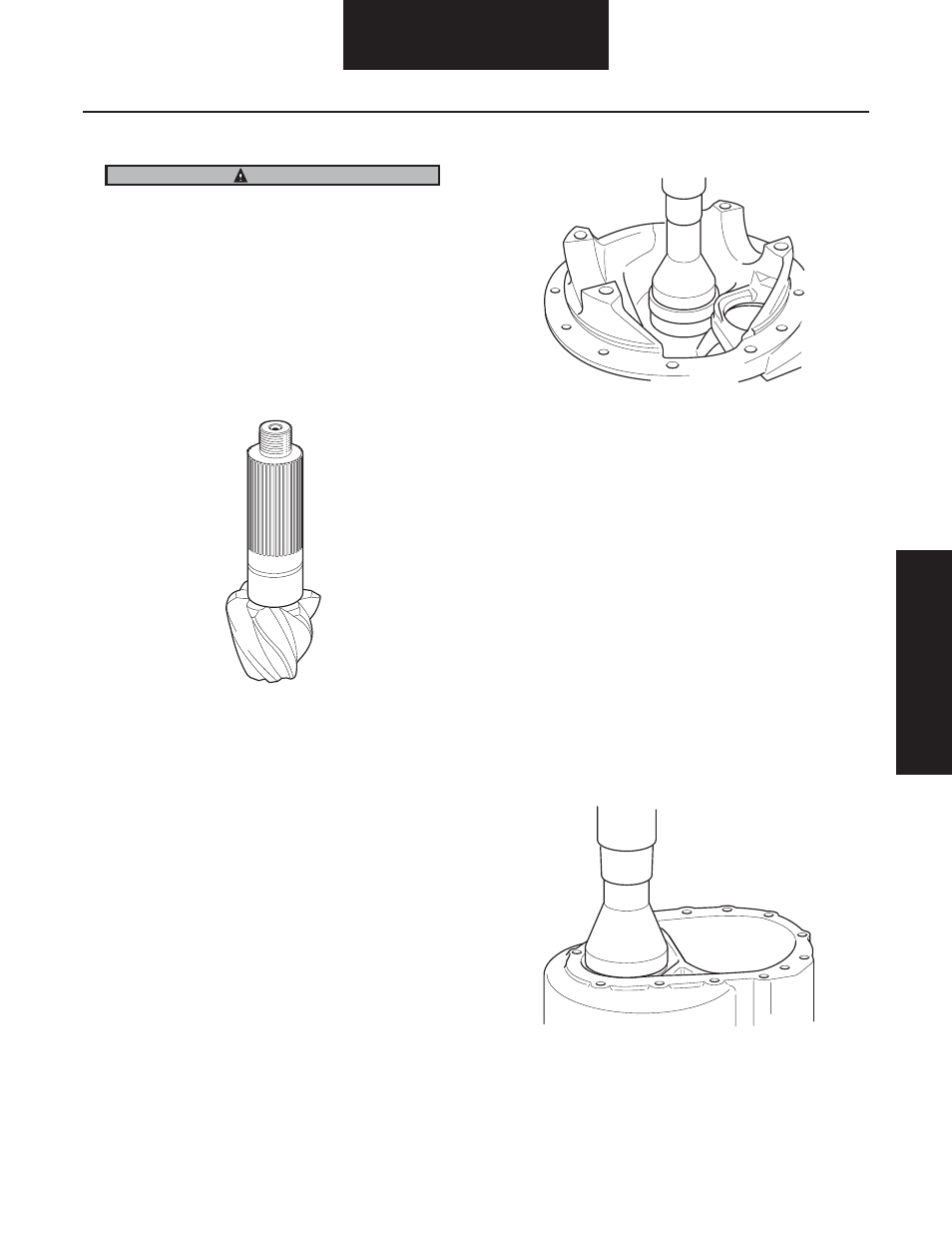

3. Use a press sleeve to install the inner bearing cone

and pilot bearing, if used, onto the pinion. Apply

pressure until the bottom of the cone touches the

shoulder of the pinion. Apply lubricant to the cone of

the bearing.

3. If removed, install the inner and outer bearing cups

into the carrier.

a. To install the inner bearing cup, place the carrier

in a press with the bottom of the carrier facing

up.

b. Place the cup in the bore, use a sleeve or

bearing driver tool to press the cup until it is

fully seated. Use a feeler gage to make sure the

cup is fully seated.

c. If replacement of the output shaft side gear

bearing cup is necessary, use either of the following

methods:

Weld: Place a weld bead around the inside of

the cup, when the weld cools the cup will fall

out.

Hammer: Use slipper to get under the cup and

with a hammer and drift from the back side of

carrier tap out bearing cup.

d. To install the outer bearing cup, place the carrier

in a press with the top of the carrier facing

up.

e. Place the cup in the bore, use a sleeve or

bearing driver tool to press the cup until it is

fully seated. Use a feeler gage to make sure the

cup is fully seated.

Note: If a press is not available, use a sleeve or bearing driver

and a hammer to install the cups.

IMPORTANT

6-39

JD77

85405

DANA

86

L70

38

Drive Pinion