Inspection – Spicer Tandem Drive Axles Service Manual D170, D190, and D590 Series User Manual

Page 10

6

Inspection

Inspection

Clean

1. Wash steel parts with ground or polished surfaces

in solvent. There are many suitable commercial

solvents available. Kerosene and diesel fuel are

acceptable.

Gasoline is not an acceptable solvent because of its

extreme combustibility. It is unsafe in the workshop envi-

ronment.

2. Wash castings or other rough parts in solvent or

clean in hot solution tanks using mild alkali solu-

tions.

Note: If a hot solution tank is used, make sure parts are

heated thoroughly before rinsing.

3. Rinse thoroughly to remove all traces of the cleaning

solution.

4. Dry parts immediately with clean rags.

5. Oil parts.

•

If parts are to be reused immediately: Lightly oil.

•

If parts are to be stored: Coat with oil, wrap in

corrosion resistant paper and store in a clean,

dry place.

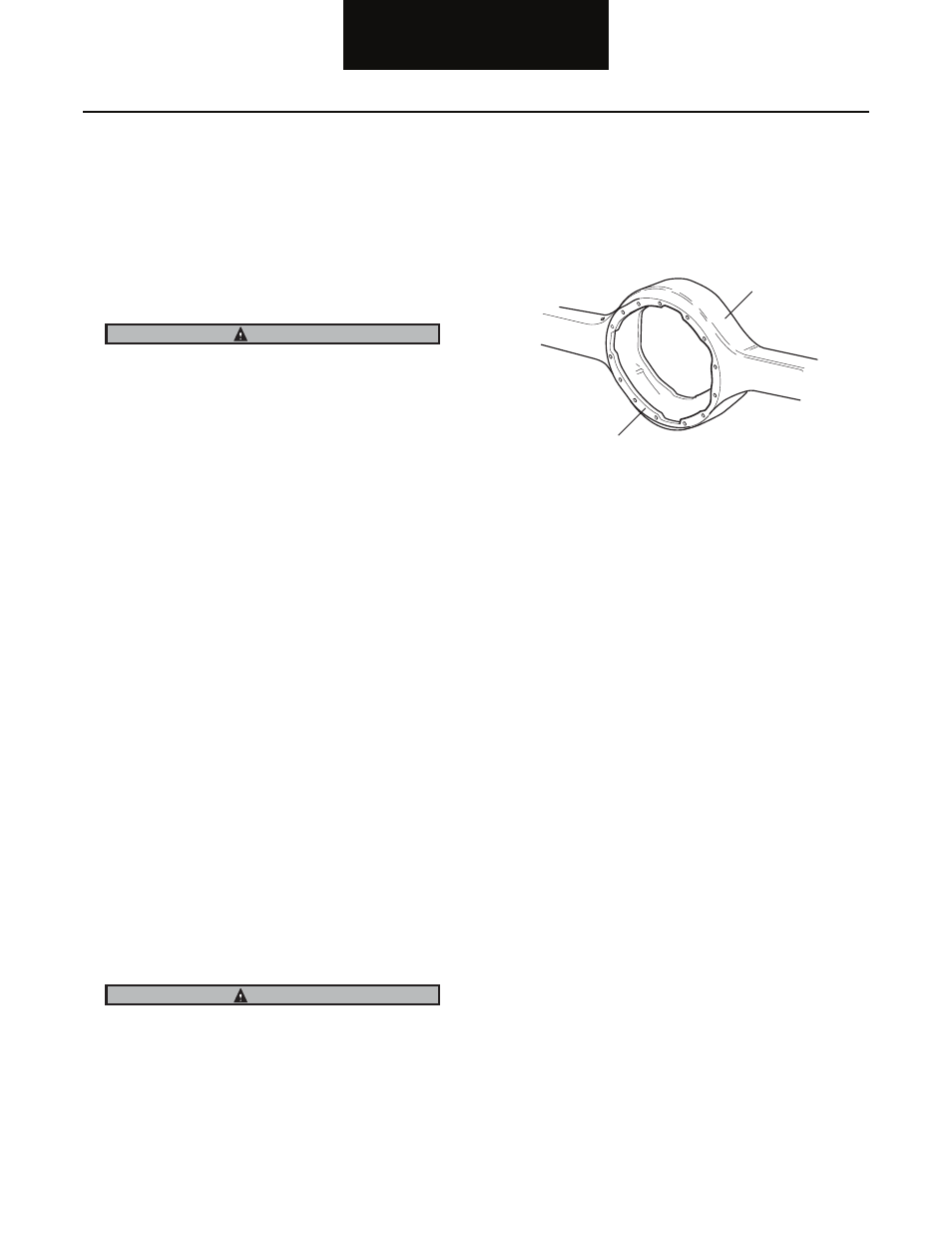

Inspect Axle Housing

Axle housing inspection and repairs are limited to the

following checks or repairs.

•

Visually inspect axle housing for cracks, nicks, and

burrs on machined surfaces.

•

Check carrier bolt holes and studs for foreign

material.

•

Replace damaged fasteners. Look for loose studs or

cross threaded holes.

Any damage which affects the alignment or structural integ-

rity of the housing requires housing replacement. Do not

repair by bending or straightening. This process can affect

the material's properties and cause it to fail completely

under load.

•

Check all seals and gaskets.

Note: Replace conventional gaskets with silicone rubber

gasket compound (included in many repair kits). The

compound provides a more effective seal against lube

seepage and is easier to remove from mating surfaces

when replacing parts.

Inspect Components

Inspect all steel parts for:

•

Notches, visible steps or grooves created by wear

•

Pitting or cracking along gear contact lines

•

Scuffing, deformation, or discolorations. These are

signs of excessive heat in the axle and are usually

related to low lubrication levels or improper lubrica-

tion practices.

In addition, inspect the following for damage:

•

Differential gearing.

•

Bearings for loose fit on drive pinion, pilot bearing,

and differential bearings.

•

All fasteners for rounded heads, bends, cracks, or

damaged threads.

•

Inspect machined surfaces of cast or malleable

parts. They must be free of nicks, burrs, cracks,

scoring, and wear.

•

Look for elongation of drilled holes, wear on sur-

faces machined for bearing fits and nicks or burrs in

mating surfaces.

Inspect Primary Gearing

Before reusing a primary gearset, inspect teeth for signs of

excessive wear. Check tooth contact pattern for evidence of

incorrect adjustment.

WARNING

CAUTION

1

2

1 - Axle housing

2 - Machined surface