Wheel hub components assembly – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 24

22

Wheel Hub Components Assembly

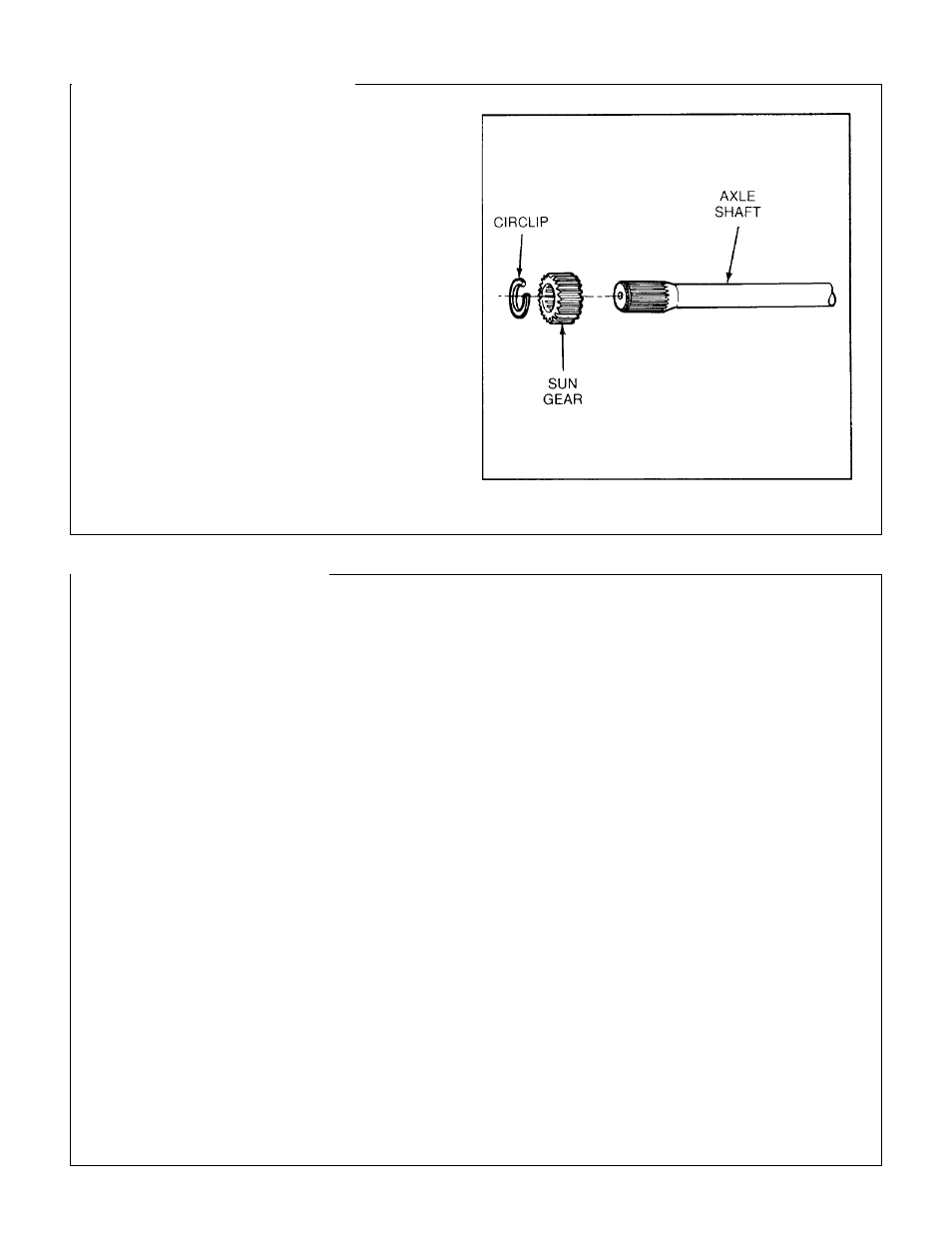

Sun Gear and Axle Shaft

1. Slide sun gear onto splines at wheel end of

axle shaft.

• The part number side of gear should be

away from shaft.

• On “D” model axles, ensure that the

double or long spline shaft end is

installed in the differential lock

cylinder side.

2. Install snap ring onto end of axle shaft.

Wheel Hub Installation

1. Install oil seal and seal band onto spindle.

2. Install wheel hub assembly on spindle.

3. Install ring gear mount assembly into hub.

4. Install washer on sindle against ring gear

support.

5. Install nut on spindle with stepped diameter

against washer. Torque nut to 250 ft.-lbs.

(350 ft.-lbs. on WR10 and 12 models).

6. Rotate hub 360

°

in both directions while

hitting hub or ring gear support with a soft

mallet.

7. Re-torque to 250 ft.-lbs. (350 ft.-lbs. on WR10

and 12 models) and repeat steps 5 and 6

until 250 ft.-lbs. (350 ft.-lbs. WR10/12) does

not advance the nut.

8. Install one (1) 126900 set screw (207357

on WR10 and 12 models) in nut, with dog

point engaging washer hole. If set screw is

being reused, coat with Loctite 277 or

equivalent. The set screw is advanced

completely when one intrnal nut thread is

showing.

• If set screw does not align with washer

hole, tighten sindle nut until next hole

aligns. Do not exceed 350 ft.-lbs.

(450 ft.-lbs. WR10/12).

9. Stake set screw in place with a center

punch at four (4) places around internal

nut thread.

10. Install sun gear and axle shaft assembly.

• A steel rod with a 1/2" thread can be

inserted into the end of the axle shaft

and used to aid shaft installation.

11. Install planetary carrier with RTV on

flange. Apply Loctite 277 to bolts. Torque

bolts to 80-95 ft.-lbs. (127-149 ft.-lbs/ pm

WR10 and12 molels.

12. Install abutment cap with RTV on flange.

Apply Loctite 277 to bolts. Torque bolts to

35-42 ft.-lbs. (45-54 on WR10/12).