Lubrication, Changing differential lubrication – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 10

8

Lubrication

Changing Differential Lubrication

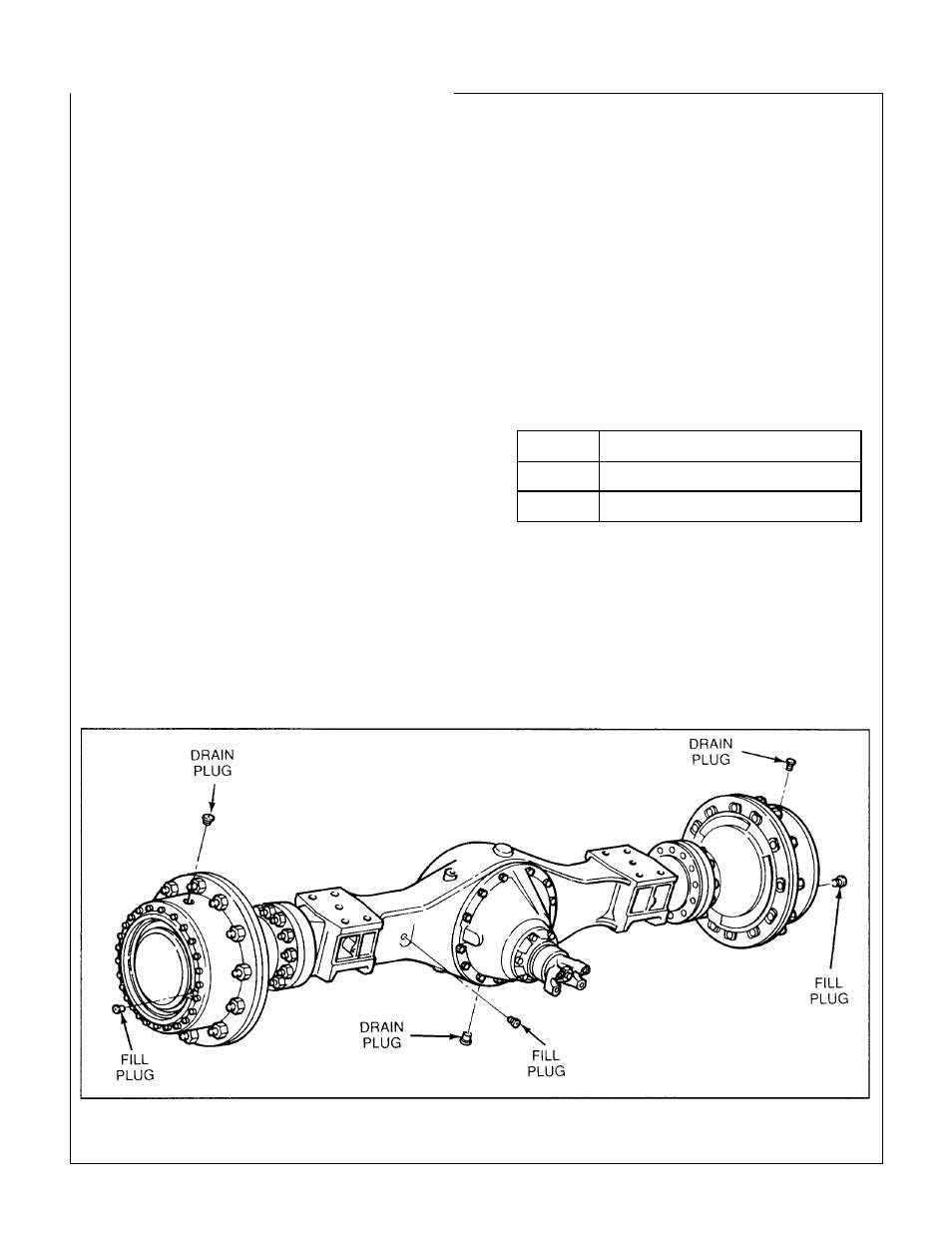

Draining

Drain when the lube is at normal operating

temperature. It will run freely and minimize the

time necessary to fully drain the axle.

1. Unscrew the magnetic drain plug on the

underside of the axle housing and allow

the lube to drain into a suitable container.

2. Inspect drain plug for large quantities of

metal particles. After initial oil change, this

condition is a sign of damage or extreme

wear in the axle. Inspection of the entire

unit may be warranted.

3. Clean the drain plug and replace it, along

with an O-Ring (WR10/12) or sealant

(WR3, 5 and 7), after the lube has drained

completely.

IMPORTANT:

Used lubricants are dangerous

environmental pollutants. Dispose of all

lubricants properly.

Filling

1. Remove the filler hole plug from right side

of housing.

2. Fill the axle with approved lubricant until

level with the bottom of the filler hole.

NOTE:

Lube fill capacities in the following

chart are good guidelines, but the actual

capacity will vary somewhat. Always use the

filler hole as the final reference. If lube is

level with the bottom of the hole, the axle is

properly filled.

Lube Capacities

WR3 WR5 WR7 WR10/12

Gallons

6

6.5

8

10

Liters

23

25

30

38