Adjustments – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 14

12

Adjustments

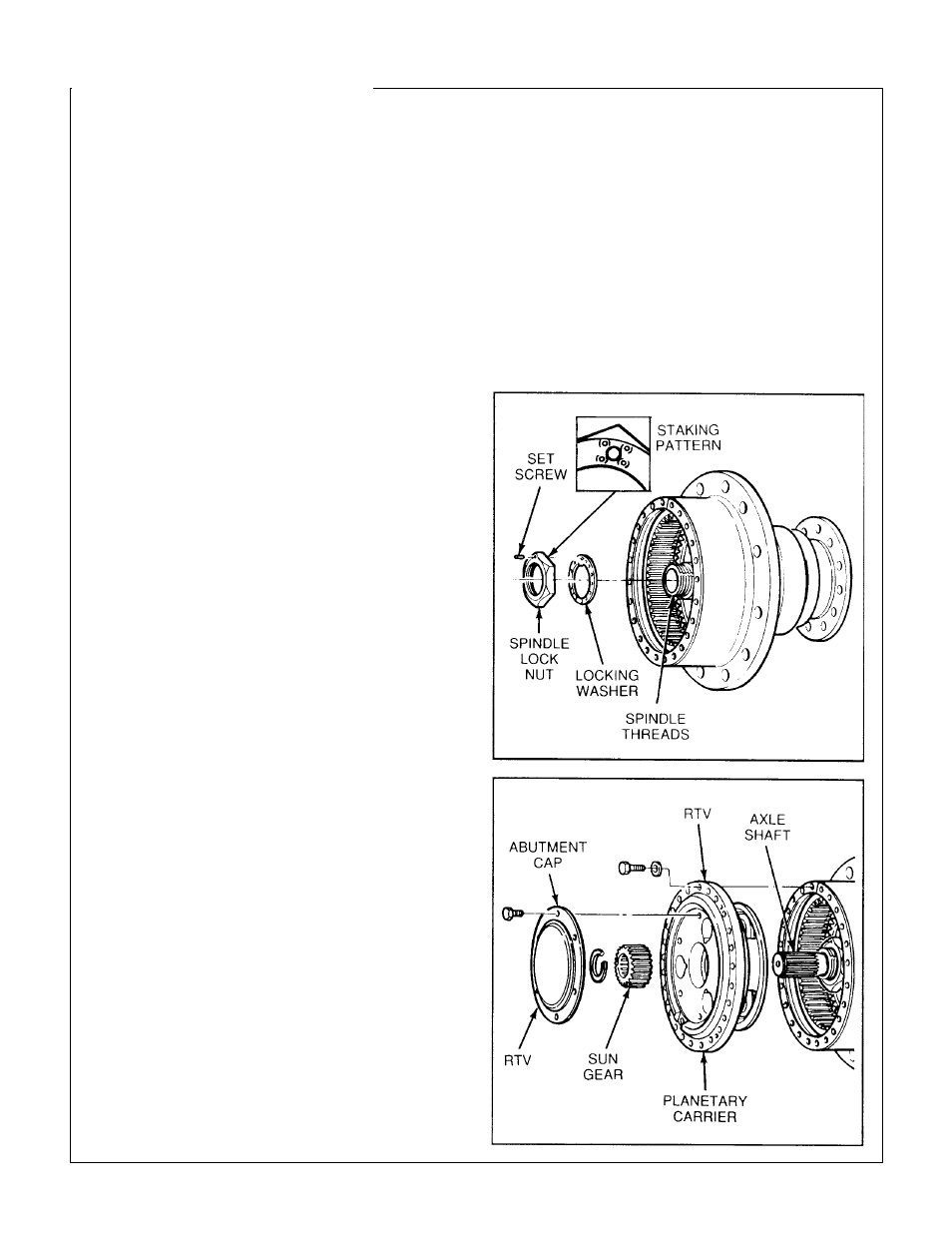

Wheel Bearing Adjustment

Wheel bearings should be adjusted at regular

intervals using the following procedure:

1. Drain wheel hub lube per instructions in this

manual.

2. Remove the planetary carrier assembly.

3. Remove the sun gear and axle shaft

assembly.

4. Remove set screw spindle lock nut and

washer.

5. Clean spindle threads carrier abutment

threads and hub threads of Loctite. Clean

all sealing surfaces.

6. Visually inspect spindle for damage or

wear. Inspect the nut and spindle threads

for damage. Apply a light coat of oil to the

spindle threads. Inspect doweled washer

and replace if damaged.

7. Install washer on spindle against ring gear

support.

8. Install nut on spindle with stepped diameter

against washer. Torque nut to 250 ft.-lbs.

(350 ft.-lbs. on WR10 and 12 models).

9. Rotate hub 360

°

in both directions while

hitting hub or ring gear support with a soft

mallet.

10. Re-torque to 250 ft.-lbs. (350 ft.-lbs. on

WR10 and 12 models) and repeat Step 9

until 250 ft.-lbs. (350 ft.-lbs. WR10/12) does

not advance the nut.

11. Install one (1) new 126900 set screw

(207357 on WR10 and 12 models) in nut,

with dog point engaging washer hole. If the

set screw is being reused coat with Loctite

277 or equivalent before installing. The set

screw is advanced completely when one

internal thread of set screw hole is showing.

• If set screw does not align with washer

hole, tighten the spindle nut until the next

hole aligns. Do not exceed 350 ft.-lbs.

(450 ft.-lbs. on WR10/12).

12. Stake set screw in place with a center

punch at four (4) places around set screw

hole thread.

13. Install sun gear and axle shaft assembly.

14. Install planetary carrier with RTV on flange.

Apply Loctite 277 or equivalent to bolts.

Torque bolts to 75-85 ft.-lbs. (149-179 ft.-lbs.

on WR10 and 12 models).

15. Install Apply abutment cap with RTV on

flange. Loctite 277 to bolts. Torque bolts to

35-40 ft.-lbs. (45-54 on WR10/12).