Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 17

Assembling (Continued)

• Check operation of differential lock by

connecting high pressure air or hydraulic

line of 140 psi supply to shift cylinder. If

this is not possible,

use a 0.75-16 UNF

bolt (but do not over torque) to manually

engage the clutches. When the fork is

adjusted correctly, curvic teeth should

be fully engaged with the fork free to

float. The shift assembly should

disengage freely.

• Recheck the .120 in. gap with the shift

cylinder fully disengaged. If not proper,

readjust using the above procedure.

• Install the pipe plug.

9. Install the indicator switch, making sure

that the plastic sealing washer is under the

switch. Tighten to 10-12 ft.-lbs. torque.

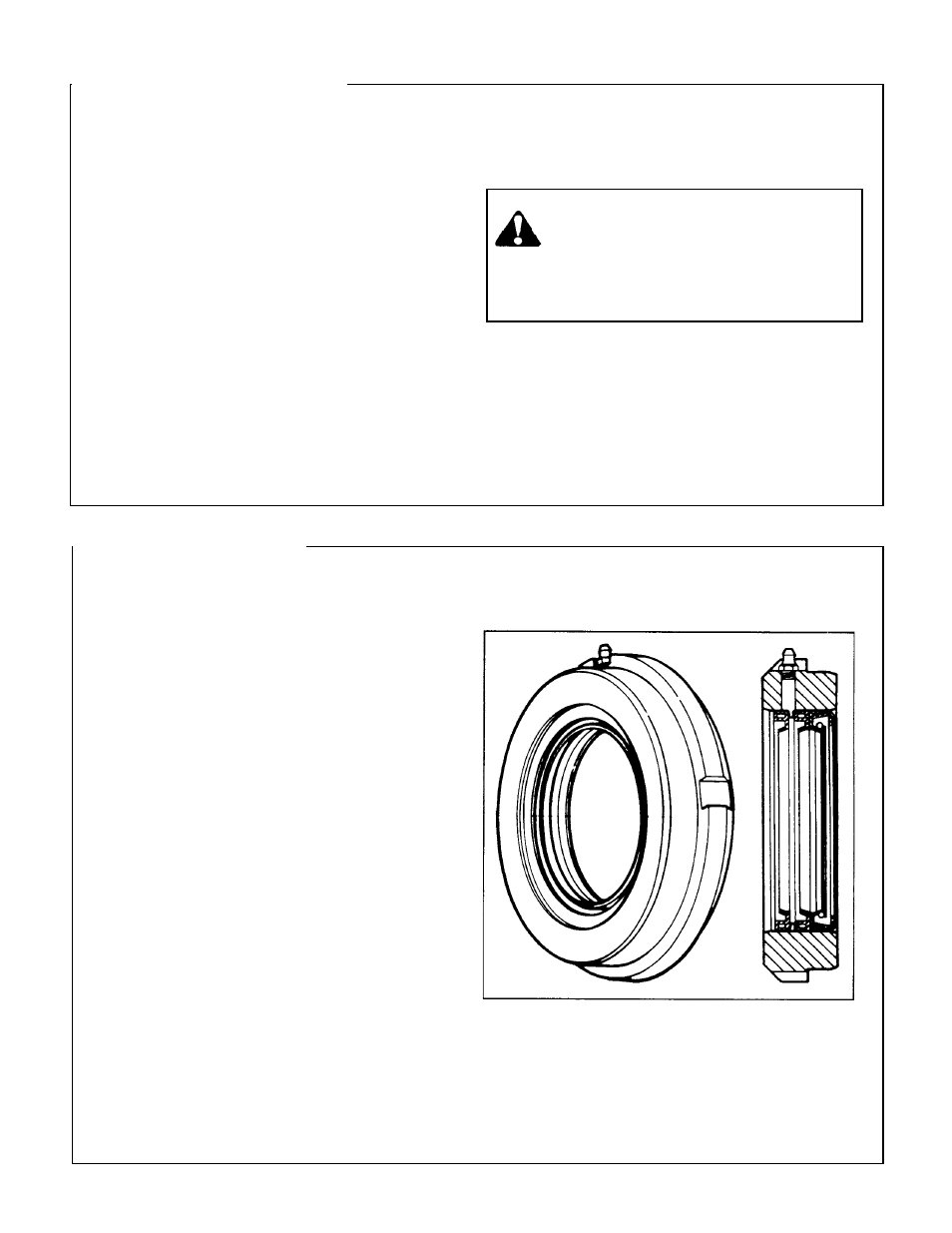

Drive Pinion Oil Seal

Removal

1. Remove input yoke according to the in

structions in the appropriate head service

manual.

2. Pry out oil seal assembly by inserting

screw drivers into notches between seal

assembly and bearing cage.

3. Remove three seals.

Installation

1. Install three seals

2. Position oil seal assembly in bearing cage

with notches at top and bottom positions

and grease fitting at the 9:00 o’clock

position

3. Drive oil seal assembly into bearing cage.

4. Install input yoke per head service manual

instructions.

15

10. To more easily drop the head into the

housing the differential lock clutches

should be engaged with a 0.75-16 UNF bolt.

CAUTION:

TURN THE BOLT INTO

THE PORT ONLY ENOUGH TO

ENGAGE THE CLUTCHES—OVER

TORQUING MAY CAUSE DAMAGE

TO THE SHIFT UNIT.

This bolt may be left in until axle shipment

to make axle shaft installation easier. Upon

shipment of the axle, remove the bolt and

replace with the plug that came with the

shift unit.