Wheel differential lock (optional equipment) – Spicer Drive Axles Service Manual Wheel Reduction Drive Axles (EA-50) User Manual

Page 16

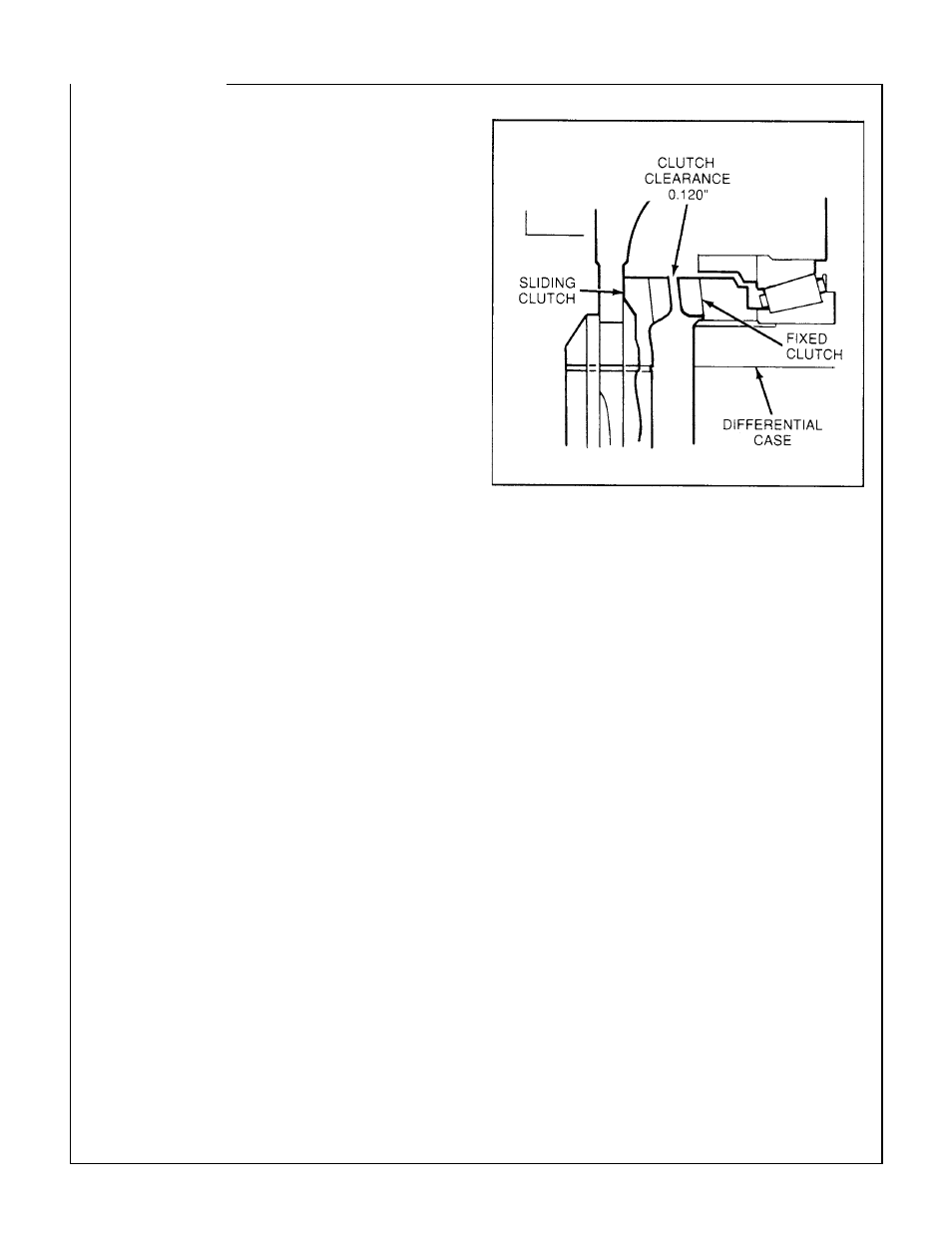

Wheel Differential Lock (Optional Equipment)

14

Assembling

1. Assemble head without differential lock

components exactly as the standard “S”

model.

2. Adjust pattern on the head tester using

standard procedures.

3. Install the fixed clutch on the flanged

differential case splined hub and fit the

retaining snap ring.

4. Install the snap ring on the pushrod.

5. Assemble shift fork, spring pin, sliding

clutch, and capscrew.

6. Assemble the pushrod through the carrier,

shift fork assembly, actuator, and return

spring in proper order and orientation per

the assembly drawing.

7. Apply a small amount of RTV sealant to

the shift cylinder flange to serve as a seal

between the shift unit and the carrier.

Install the shift cylinder assembly over the

pushrod orienting the cylinder so that the

breather port is facing up as the axle will

be installed in the vehicle. Compress the

assembly to keep the pushrod piloted in

the carrier. The spring force is higher for

the hydraulic shift than the air shift version

so expect higher forces to compress the

assembly. Tighten the two shift cylinder

mounting screws (longer than those used

on the air shift unit) to 28-35 ft.-lbs.

8. Adjust the shift fork position using the

following procedure:

• Fit a dummy shaft through the sliding

clutch into the differential side gears.

• Place a 0.120 in. feeler gauge between

the tips of the curvic clutch teeth and

slide the shiff fork along the push rod to

set clutch clearance at 0.120 in. as

shown in the illustration

• Tighten shift fork capscrew to 26-30

ft.-lbs.