Steering knuckle assembly – Spicer Dana Spicer Steer Axles - Service Manaul User Manual

Page 27

23

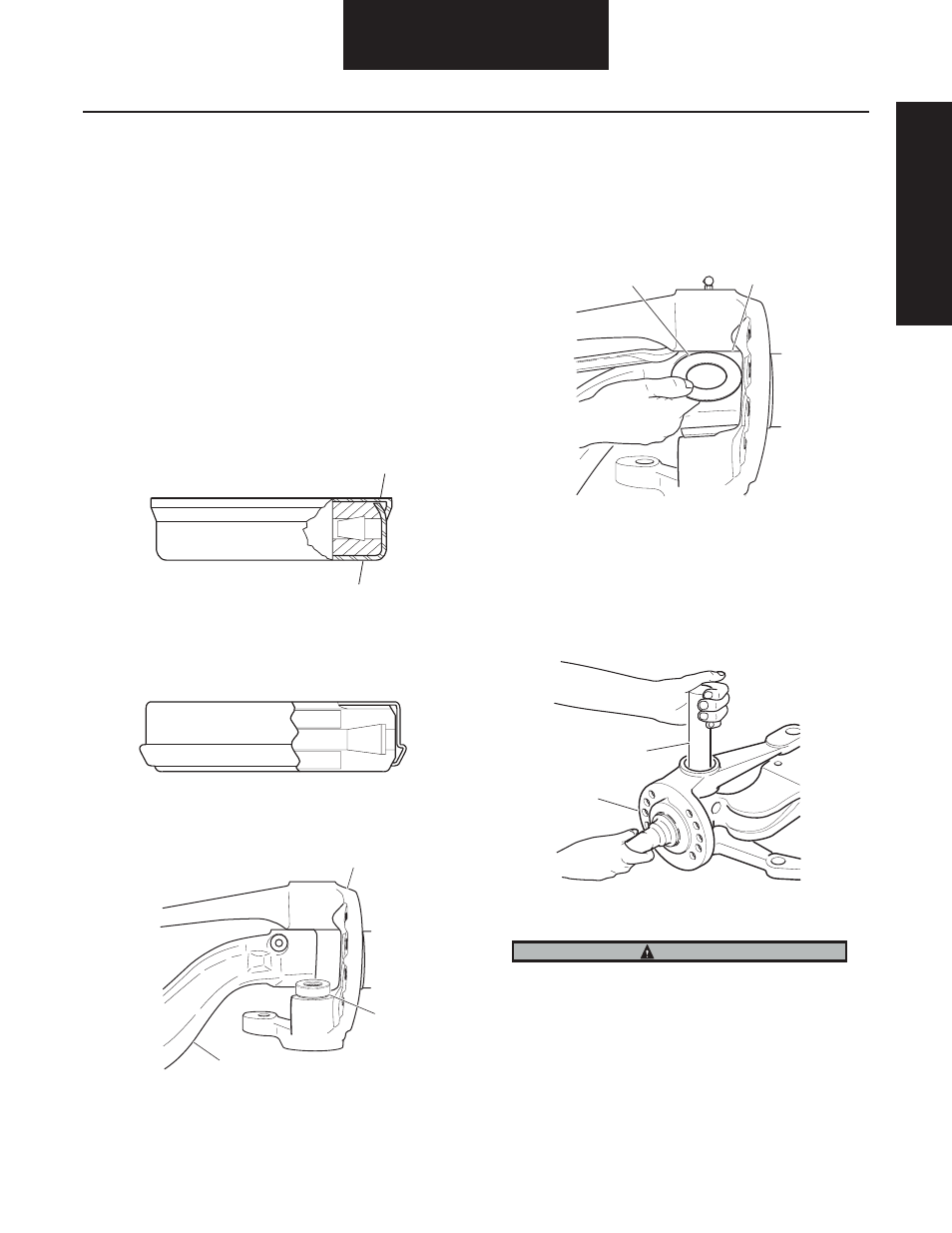

Disassembly, Overhaul, and

Assembly

Disassembl

y, Overhaul,

and Assembl

y

Steering Knuckle Assembly

Note: Always replace kingpin, thrust bearing and bushings if

any component is faulty.

1. Before installing the kingpins, lubricate inside of

bushing and outside of kingpins with Fleetrite EP2

Moly Grease or equivalent NLGI No. 2 multipurpose

lithium grease to provide initial lubrication.

2. Make certain that kingpin hole in axle center is clean

and dry.

3. There may be two styles of thrust bearings. One type

is installed on thrust bearing with seal on top, as

show in the following figure. Position and support

the steering knuckle assembly on the axle end.

4. The second style thrust bearing is a one piece design

with seal LIP installed TOWARDS the bottom of the

knuckles as show in the following figure.

5. Slide the thrust bearing between the lower face of

axle center and lower steering knuckle yoke.

6. Align the steering knuckle yoke holes with axle and

thrust bearing holes.

7. Pre-adjust knuckle vertical play by wedging the

steering knuckle up and filling the gap at the top side

of the knuckle with shim(s).

Note: Floor jack can be used to wedge up steering knuckle.

8. Install kingpin from the top with notch and draw key

hole aligned. Hand start pin in bushing.

1 - Seal cap

2 - Thrust bearing

1 - Steering knuckle

2 - Thrust bearing

3 - Axle beam

1

2

1

3

2

1 - Install shim(s) as needed

2 - Shim only top of knuckle

1 - Kingpin

2 - Steering knuckle

Never shim on the bottom side of the beam.

1

2

1

2

CAUTION