Tie rod inspection, Inspection – Spicer Dana Spicer Steer Axles - Service Manaul User Manual

Page 13

9

Inspection

Inspection

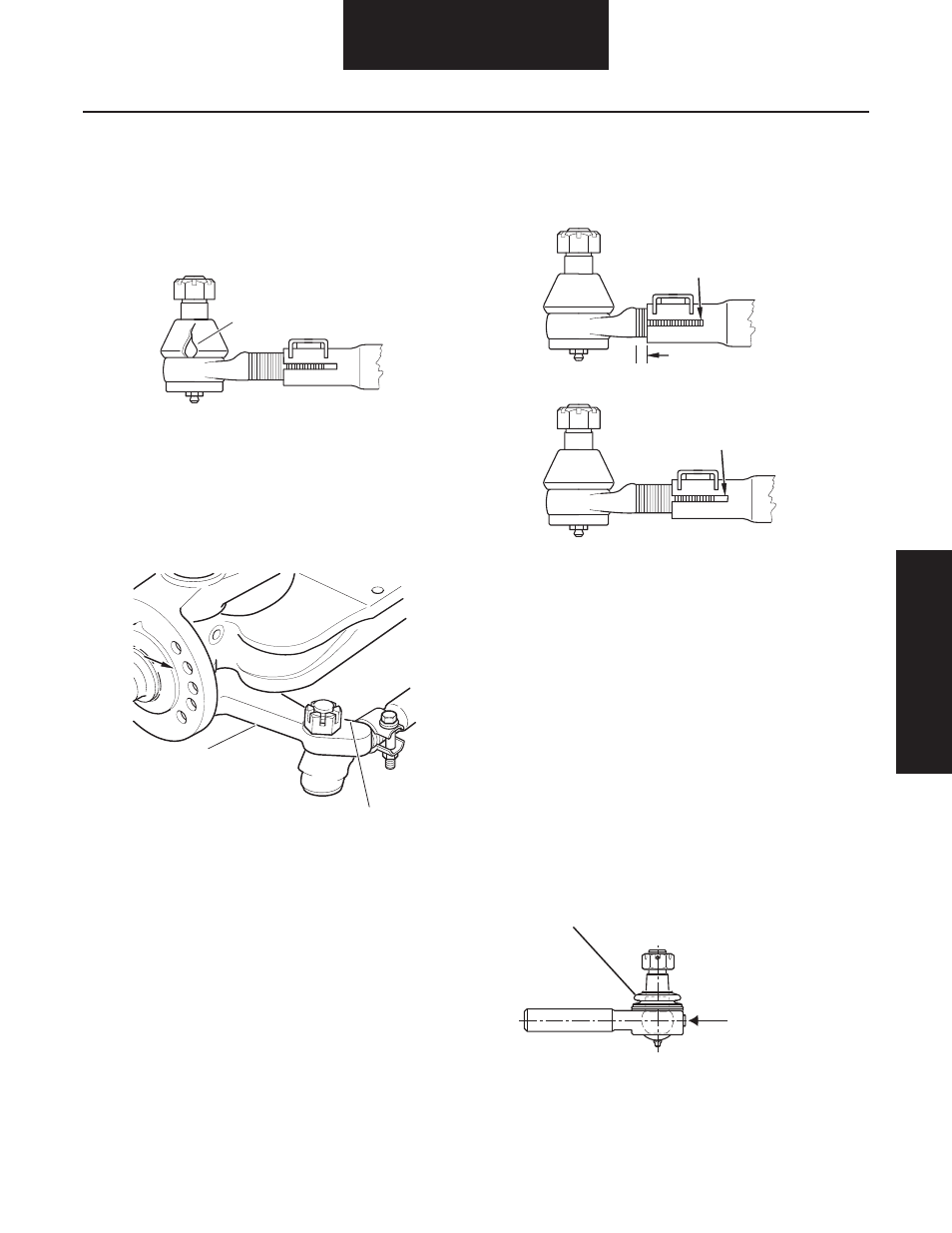

Tie Rod Inspection

1. Make sure the boot completely covers the ball joint

of the tie rod end with no cracks or tears. If there is

damage to the boot, the entire tie rod end must be

replaced.

2. Make sure the tie rod nut is torqued to the proper

specifications and the cotter pin is correctly installed

in the nut. If the cotter pin is missing, the tie rod nut

could become loose and steering will be affected.

3. The threaded portion of each tie rod end must be

inserted completely in the cross tube split. This is

essential for adequate clamping. Replace compo-

nents if this fit cannot be obtained.

4. Where zerk fittings are necessary, make sure they

are installed correctly. (Non-greaseable tie rod ends

do not require zerk fittings.)

5. To protect the cross tube, use only your hands or a

pipe wrench with jaw protectors to rotate the cross

tube. Make sure the cross tube will turn toward the

front and the back of the vehicle. Replace both of the

tie rod ends if they will not turn in both directions.

6. If the cross tubes or clamps are bent, cracked or

damaged, replacement is necessary. Do not attempt

to repair a cross tube as this could result in damage

to the axle.

7. Proper positioning of clamp relative to beam and

correct orientation of nut and bolt are required to

ensure clearance at high wheel cuts.

Note: Tie rods end inspections should always be performed

prior to lubrication. If the inspection is performed after

lubrication, there may be a false indication that the tie

rod end is fully operative.

1 - Cracked or torn boot requires entire tie rod end replace-

ment

1 - Steering knuckle

2 - Missing cotter pin

1

1

2

The threaded portions of both

tie rod ends must be completely

inserted in cross tube split

Threaded end is not completely

inserted in cross tube split

CORRECT

INCORRECT

Equal threads exposed on

left and right tie rod ends

Boot does not have purging capibilities.

All grease purging takes place through

pureable grease fitting.

Purgeable

grease fitting