Install system water piping, Manual, System water piping methods – Weil-McLain PLUS LINE PLUS-E017-A/1206 User Manual

Page 25: Expansion tank and make-up water, Boiler circulator, Sizing space heat system piping

Part Number PLUS-E017-A/1206

2

Manual

• Installation • Start-Up • Usage • Maintenance • Parts

Install system water piping

(space heating)

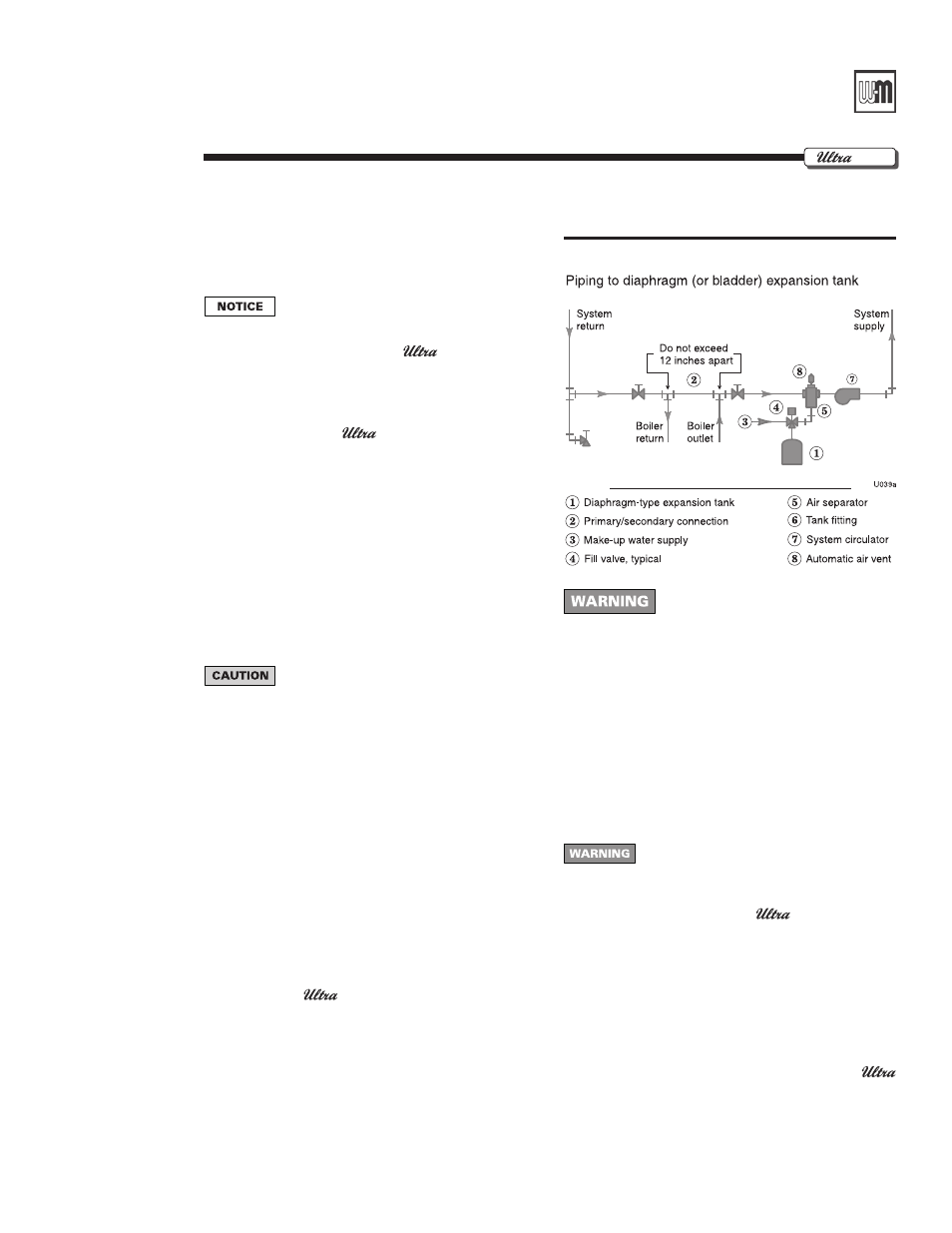

Figure 11

Expansion tank piping

B1

Gas

System water piping

methods

All piping methods shown in this manual

use primary/secondary connection to the

boiler loop. These designs ensure proper

flow through the

Gas boiler, for

the most efficient and reliable operation

of the boiler and the heating system. For

other piping methods, consult your local

Weil-McLain representative or refer to

separate

Gas boiler piping guides.

Wall-mounted boilers — Piping can exit

bottom of boiler enclosure. See separate

wall-mounting instructions for details.

Expansion tank and make-up

water

1. Ensure expansion tank size will handle boiler and

system water volume and temperature. Allow

gallons for the boiler and its piping.

Undersized expansion tanks cause system

water to be lost from relief valve and

make-up water to be added through fill

valve. Eventual boiler failure can result

due to excessive make-up water addi-

tion.

2. Tank must be located as shown in this supplement,

or following recognized design methods. See tank

manufacturer’s instructions for details.

. Connect the expansion tank to the air separator

only if the separator is on the suction side of the

system circulator. Always install the system fill con-

nection at the same point as the expansion tank

connection to the system.

. The piping drawings in this manual show only

diaphragm expansion tanks. Use only bladder-type

or diaphragm-type tanks with PLUS indirect water

heater applications.

. Refer to the

Boiler Manual for other system

piping examples.

Diaphragm (or bladder) expansion tank

1. Always install an automatic air vent on top of the air

separator to remove residual air from the system.

2. See Figure 11 for correct location of the expansion

tank.

DO NOT USE a closed-type expansion tank

The boiler-side piping must be

equipped with a diaphragm- or

bladder-type expansion tank, NOT

a closed-type expansion tank. This

is necessary to allow venting air

from the top of the indirect water

heater boiler-side.

Boiler circulator

The boiler circulator is shipped loose. It must be located

in either the return or supply piping, as shown in the

appropriate piping diagram in this supplement or the

Boiler Manual.

DO NOT use the boiler circulator in any

location other than those shown in this

manual or the boiler manual. The boiler

circulator is selected to ensure adequate

flow through the

boiler. Failure to

comply could result in unreliable per-

formance and nuisance shutdowns from

insufficient flow.

Sizing space heat system

piping

1. See Figures 12 and 1, pages 2 and 2, or the

Gas Boiler Manual for recommended piping. In all

diagrams, the space heating system is isolated from

the boiler loop by the primary/secondary connec-

tion.

2. Size the piping and components in the space heating