Prepare boiler location — clearances, Gold cgs gas-fired water boiler — boiler manual, Recommended service clearances – Weil-McLain GOLD CGS 550-110-260/0107 User Manual

Page 7: Required minimum clearances, Flooring, Foundation, Residential garage installations

Part number 550-110-260/0107

GOLD CGs Gas-Fired Water Boiler — Boiler Manual

Prepare boiler location — clearances

1b

Figure 2

Required MINIMUM clearances

Figure 1

Recommended

SERVICE

clearances

(see

WARNING

below)

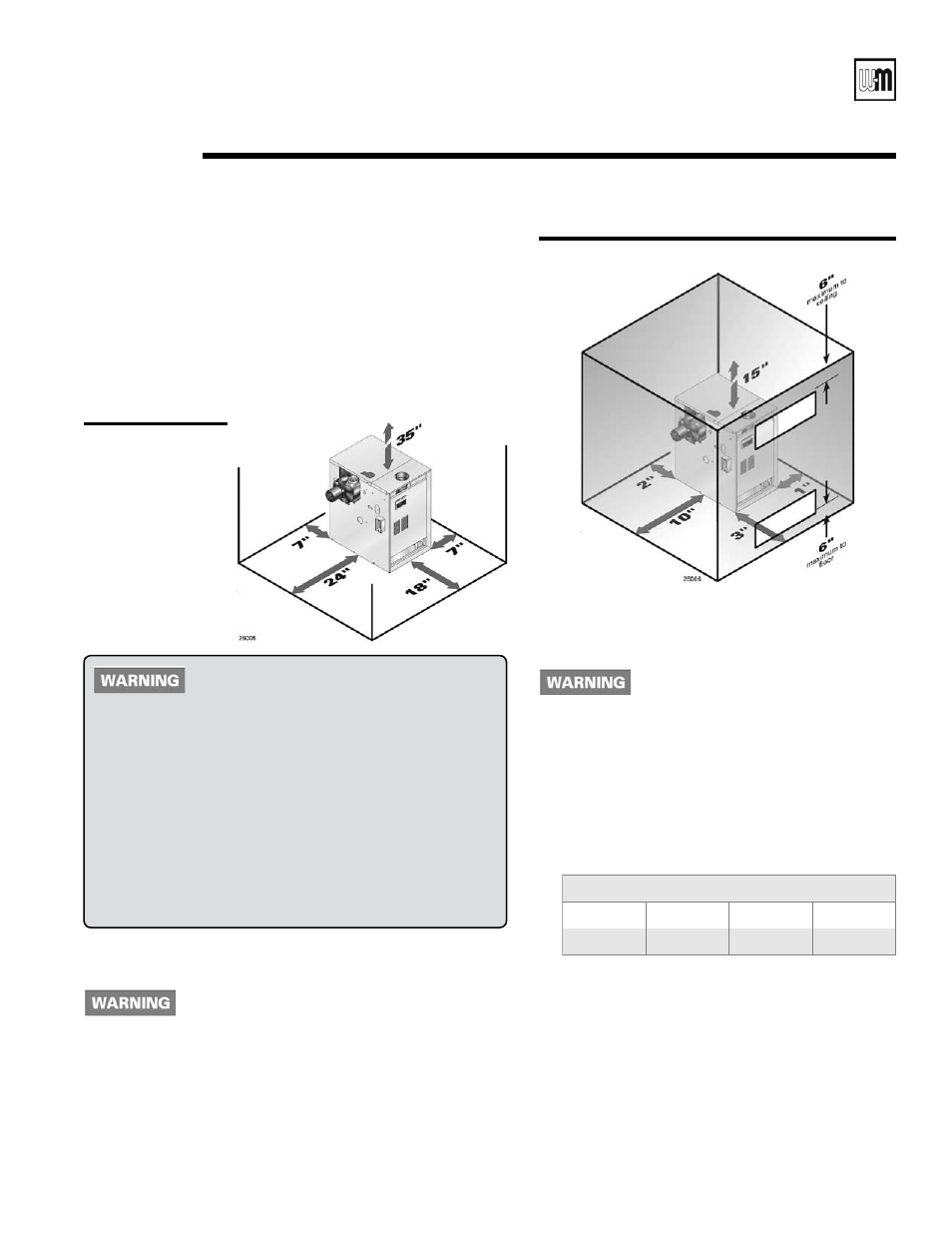

Recommended SERVICE clearances

(Fig. 1)

1. Provide clearances for cleaning and servicing the boiler and for

access to controls and components. See Figure 1 for recommenda-

tions.

. Provide at least screwdriver clearance to jacket front panel screws

for removal of front panel for inspection and minor service. If

unable to provide at least screwdriver clearance, install unions and

shutoff valves in system so boiler can be moved for servicing.

Required MINIMUM clearances

(Fig. 2)

Never install the boiler in a space with clear-

ances less than the minimum clearances shown

in Figure 2

. Failure to comply can result in severe

personal injury, death or substantial property

damage and reduced boiler life.

1.

Hot water pipes:

at least ¹⁄₂ inch

from combustible material.

.

Single-wall vent pipe:

at least 6 inches

from combustible mate-

rial.

3.

Type B double-wall metal vent pipe

: refer to vent manufacturer’s

recommendation for clearances to combustible material.

If any clearance is less than in Figure

1, provide

openings for combustion and ventilation air

located on the wall or door opposite the boiler

FRONT (see Figure 2)

.

These openings must be located as shown in Figure to provide

proper air flow around the boiler. The free area of each opening

(after deducting for louvers) must be at least

one square inch per

1,000 Btuh

of boiler input. If the building is of unusually tight

construction (see page 10 for definition), the air openings must

connect directly to outside or the building must have air openings

to the outside as specified on page 10.

If clearances are equal to or greater than Figure 1, see pages 10

and 11 for location and sizing of combustion air openings.

Failure to comply can result in severe personal injury, death or

substantial property damage and reduced boiler life.

Flooring

The CGi boiler is approved for installation on combustible

flooring, but must never be installed on carpeting.

Do not install boiler on carpeting even

if foundation is used. Fire can result,

causing severe personal injury, death

or substantial property damage.

Foundation

1. Provide a solid brick or minimum -inch thick concrete

foundation pad if any of the following is true:

• floor can become flooded.

• the boiler mounting area is not level.

. Minimum dimensions are

25” length

by:

Minimum foundation width

CGs-3

15”

CGs-5

21”

CGs-4

18”

CGs-6

24”

Residential garage installations

Take the following special precautions when installing the

boiler in a residential garage. If the boiler is located in a

residential garage, per ANSI Z3.1:

• Mount the boiler a minimum of

18 inches above the

floor

of the garage to assure the burner and ignition

devices will be no less than 18 inches above the floor.

• Locate or

protect the boiler

so it cannot be damaged

by a moving vehicle.