Toshiba B-SV4T-GS10-QM User Manual

Page 27

APPENDIX 1 SPECIFICATIONS

ENGLISH VERSION

A1.3 Media

EA1- 3

A1.3.1 Media Type (Cont.)

Unit: mm (inch)

Issue mode

Item

Batch mode

Strip mode

Cut mode

Width including backing paper

25.4 to 112 (1.0 to 4.4)

Media width

Min. 17 (0.7)

Media pitch

10 to 1000(0.39 to 39.3)

25.4 to 1000 (1.0 to 39.3)

Media length

Min. 10 (0.39)

Min. 25.4 (1.0)

Gap length (or black mark length)

Min. 2

Min. 6

Black mark width

Min. 8

Thickness

0.06 to 0.19

Max. outer roll diameter

Ш127 (5)

Ш214 (8.4): When the optional External Media Roll Hanger is used.

Roll direction

Either is acceptable.

Outside roll media; Linerless paper (option)

Inner core diameter

25.4, 38.1, or 76.2 (1, 1.5, or 3)

(See NOTE 2.)

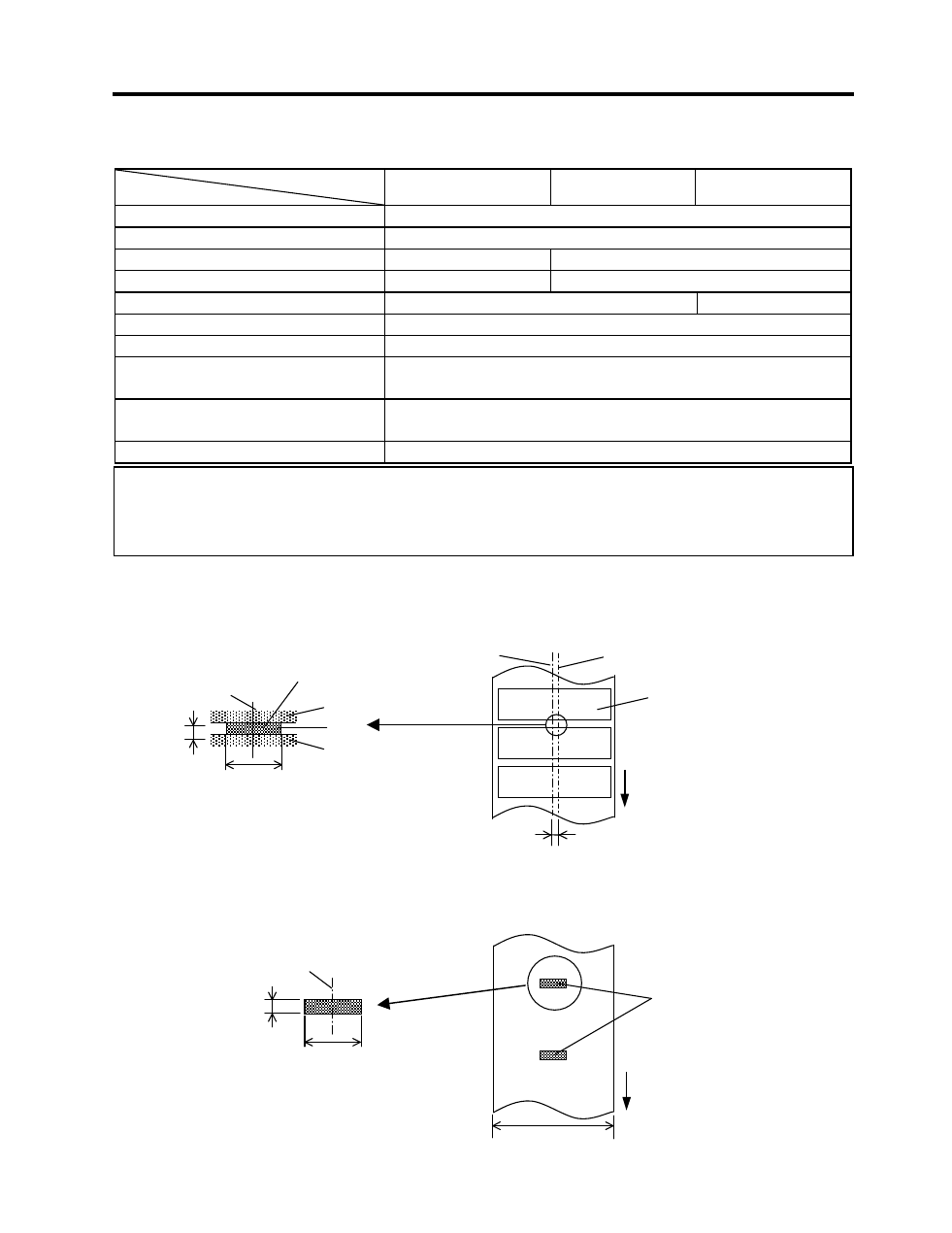

A1.3.2 Detection Area of the Transmissive Sensor

The Transmissive Sensor is positioned 6 mm from the centre.

The Transmissive Sensor detects a gap between labels, as illustrated below.

A1.3.3 Detection Area of the Reflective Sensor

The Reflective Sensor is movable within the full range of the media width.

The reflection factor of the Black Mark must be 10% or lower with a waveform length of 950 nm.

The Reflective Sensor should be aligned with the centre of the Black Mark.

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC approved media.

2. When using a media roll of 76.2-mm (3”) inner core diameter, the 3”-Diameter Media Shaft included in the

optional External Media Roll Hanger is required.

Min. 2 mm

(Min. 6 mm:

cut mode)

Min. 8 mm

Sensor position

Area to be detected.

Label

Gap

Label

Centre of media

Sensor position

Media feed direction

6 mm

Print side

Min. 2 mm

(Min. 6 mm:

Cut mode)

Min. 8 mm

Sensor should be positioned at the

centre of the black mark.

Media feed direction

Detecting the black marks on

the back.

Sensor is movable within the full range.