Selection procedure – Trane RT-PRC010-EN User Manual

Page 17

17

RT-PRC010-EN

Selection

Procedure

ITD = 190 F - 65.4 F = 125 F. Divide the

winter heating load by ITD = 563 MBh ÷

125 F = 4.50 Q/ITD.

From Table PD-31, select the low heat

module. By interpolation, a Q/ITD of 4.50

can be obtained at a gpm at 25.7.

Water pressure drop at 25.7 gpm is 0.57

ft. of water. Heat module temperature

rise is determined by:

Total Btu =

∆

T

1.085 x Supply cfm

563,000 = 29.7 F

(1.085 x 17,500)

Unit supply air temperature = mixed air

temperature + air temperature rise = 65.4

+ 29.7 = 95 F.

Steam Heating System

Assume a 15 psig steam supply.

From Table PD-27, the saturated

temperature steam is 250 F. Subtract

mixed air temperature from the steam

HEATING CAPACITY SELECTION

Step 1 — Determine Air Temperature

Entering Heating Module

Mixed air temperature = RADB + % OA

(OADB - RADB) = 70 + (0.10) (0 - 70) = 63

F

Supply air fan motor heat temperature

rise = 46,000 Btu ÷ (1.085 x 17,500 cfm) =

2.42 F

Air temperature entering heating

module = 63.0 + 2.42 = 65.4 F

Step 2 — Determine Total Winter Heating

Load

Total winter heating load = peak heating

load + ventilation load - supply fan

motor heat = 475 + 133 - 46.0 = 562 MBh

Electric Heating System

Unit operating on 460/60/3 power supply.

From Table PD-30, kw may be selected

for a nominal 50 ton unit operating

460-volt power. The 170 kw heat module

(580.1 MBh) will satisfy the winter

heating load of 563 MBh.

Table PD-28 shows an air temperature

rise of 30.6 F for 17,500 cfm through

the 170 kw heat module.

Unit supply temperature at design

heating conditions = mixed air

temperature + air temperature rise = 65.4

F + 30.6 F = 96.0 F.

Gas Heating System (Natural Gas)

From Table PD-24 select the high heat

module (697 MBh output) to satisfy

winter heating load of 563 MBh at unit

cfm.

Table PD-26 also shows an air

temperature rise of 36.0 F for 17,500 cfm

through the heating module.

Unit supply temperature at design

heating conditions = mixed air

temperature + air temperature rise = 65.4

F + 36.0 F = 101.4 F.

Hot Water Heating

Assume a hot water supply temperature

of 190 F. Subtract the mixed air

temperature from the hot water

temperature to determine the ITD (initial

temperature difference).

temperature to determine ITD. ITD = 250

F - 65.4 F = 185 F.

Divide winter heating load by ITD =

563 MBh ÷ 185 F = 3.04 Q/ITD.

From Table PD-26, select the high heat

module. The high heat module at 17,500

cfm has a Q/ITD = 5.11.

Heat module capacity, Q = ITD x Q/ITD =

185 F x 5.11 Q/ITD = 945 MBh

Heat module air temperature rise

= Total Btu

1.085 x Supply cfm

945 Btu ÷ (1.085 x 17,500 cfm) = 49.8 F.

Unit supply temperature at design

conditions = mixed air temperature + air

temperature rise = 65.4 F + 49.8 F = 115 F.

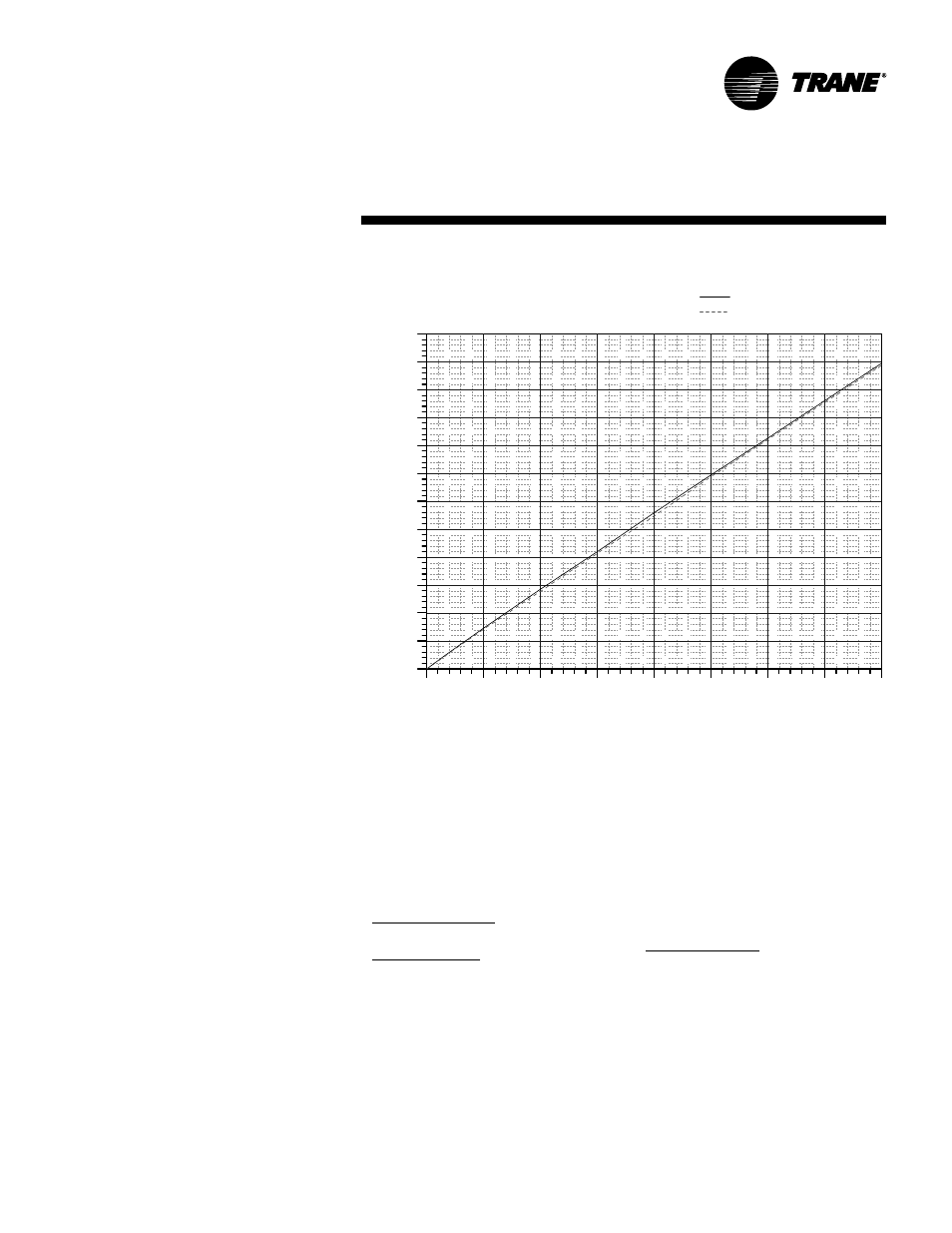

Chart SP-1 — Fan Motor Heat

0

5

10

15

20

25

30

35

40

0

10

20

30

40

50

60

70

80

90

100

110

120

STANDARD MOTOR

HIGH EFFICIENCY MOTOR

F

A

N

M

O

T

O

R HE

A

T

-

M

B

H

MOTOR BRAKE HORSE POWER