Connections – TurboChef Technologies 3240 User Manual

Page 15

ST

AR

T-UP

11

Gas

Activate maintenance mode (refer to page 9) if necessary.

An Electronic Manometer must be used to properly set

all pressures. If the minimum pressure is not set cor-

rectly, the oven temperature will slowly rise in stand-by

mode and eventually cause cooking issues as well as trip

the high limit temperature switch. Electronic Manom-

eters (HHC-3001) are available through TurboChef; call

800.90

TURBO

(+1 214-379-6000) for pricing and

1. Verify the type of gas being supplied to the oven —

natural, propane/L.P, I

2H

, I

2E

, I

2E+

, I

2L

, or I

3P

.

2. Verify the type of gas to which the oven was factory-

set to operate. Check the data plate on the rear of the

oven (this should match the type of gas being

supplied to the oven).

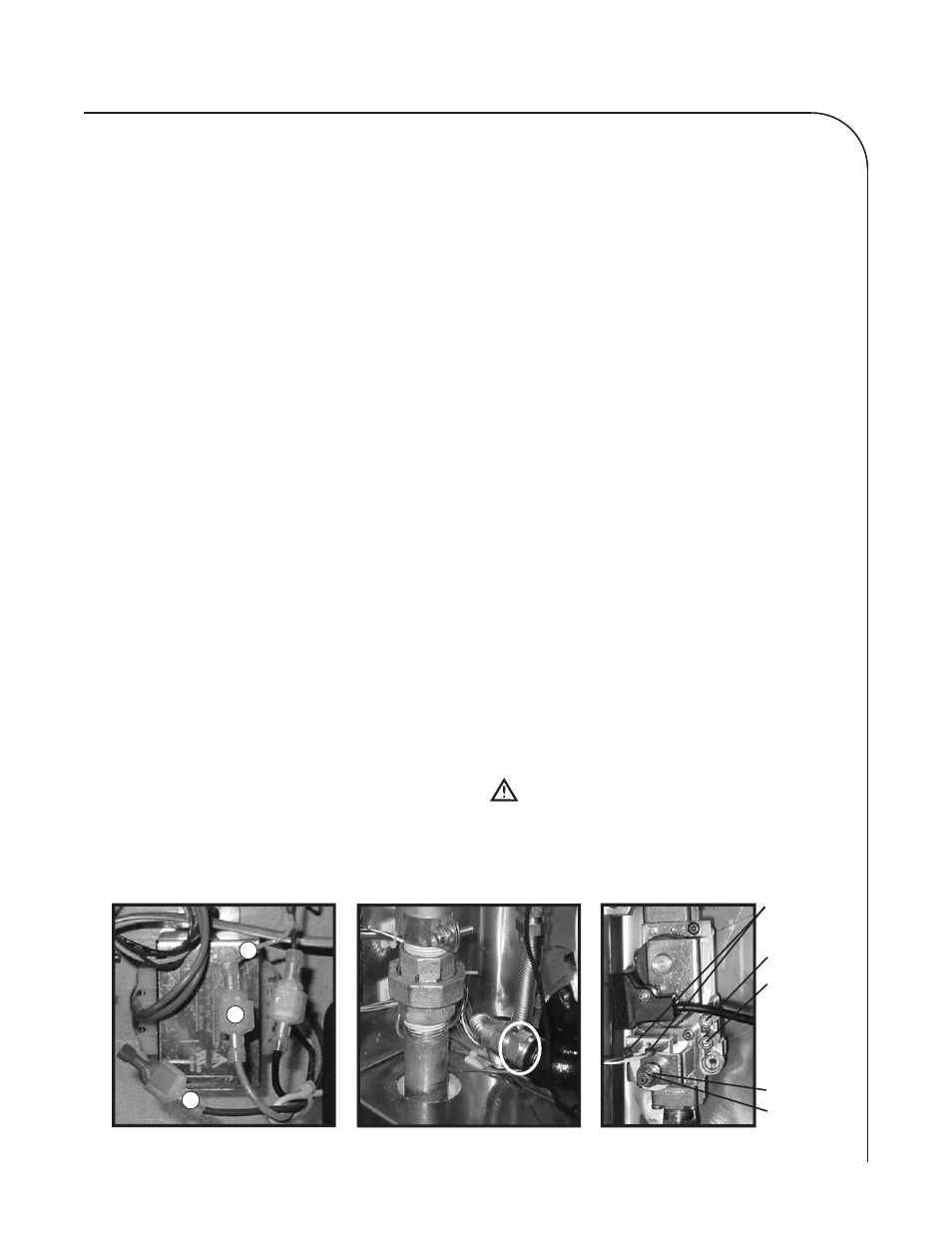

3. Verify the proper orifi ce is installed and it matches

the description of the data plate. The orifi ce (fi g.

Gas, Step 3) is located at the base of the fl ex

connector attached to the burner inlet. A blue orifi ce

is used for natural gas. A yellow orifi ce is used for

propane/L.P.

gas.

4. Verify the incoming gas pressure (static). This is the

pressure sent to the oven from the existing piping

system when all of the equipment in the piping

system is off (pilot lights are acceptable). Take this

reading from the upper tap of the gas valve (fi g. Gas,

Steps

4-7). This tap will show the incoming pressure

before the internal regulator of the gas valve. This

(static) reading is to be taken with the oven off and

with all of the other appliances in this piping system

also

off.

WARNING: The pressures must be no less than

6” W.C. (152.4 mm H

2

O, 14.94mb) and no more

than 14” W.C. (350.6 mm H

2

O, 34.87 mb).

Otherwise, severe damage to the equipment can

occur.

Connections

Leak-testing all connections is required.

NOTE:

TurboChef suggests using a soap solution;

however, check with the local code authority to ensure

that no other test is required (refer to the regulations

in force in the country in which the appliance is being

installed). The prevailing authority is the local code (or

regualtions).

1. Soap-test all connections for gas leaks.

a. Turn on the gas supply.

b. Spray all gas connections with a soap solution.

-If growing soap bubbles are observed, a leak is

present. Immediately shut off the gas supply.

-If no growth occurs, the connections are intact.

Turn off the gas supply.

2. Verify the size of the breaker. For North America,

20 Amp independent circuit is required, for EU/Asia

a 16 Amp independent circuit is required.

3. Ensure there is an individual breaker per unit for

multiple oven locations.

4. Ensure the factory-supplied plug is used, or note any

differences on the Start-up Checklist.

5. Write the voltage readings at the incoming voltage

terminal block on the Start-up Checklist.

6. Verify the 24 VAC transformer confi guration: 208 or

240. The oven is shipped with the transformer’s

primary wiring disconnected. Determine the voltage

on site during the start-up process and connect the

transformer accordingly. See fi gure Connections,

-208 VAC installation: connect wire B (blue) to wire

C (blue). The fi gure below is confi gured for 208

VAC

operation.

-240 VAC installation: connect wire A (red) to wire

C

(blue).

NOTE: The oven will not operate until this task is

completed.

Connections, Step 6

A

B

C

Gas, Step 3

Gas, Steps 4-7

Upper Tap

5mm nut

Red or White

Wire

Lower Tap

8mm nut

Step 6.

availability.