6 paper jam detection – Oki 4M User Manual

Page 32

2 - 19

2.6

Paper Jam Detection

The OKIPAGE 4w Plus/4m monitors the paper status when the power supply is on and during

printing. In the following cases, the OKIPAGE 4w Plus/4m interrupts the printing process as a

paper jam. Printing can be recovered by opening the cover, removing the jammed paper, and

closing the cover.

Error

Paper inlet jam

•

•

Only the manual feed sensor detects "Paper exists" when the power supply is on.

The leading part of the paper does not reach the paper sensor although hopping

operation was performed three time.

Cause of Error

Paper feed jam

• The leading part of the paper does not reach the outlet sensor within a fixed time after it

has passed the paper sensor.

Paper outlet jam

• The trailing part of the paper does not pass the outlet sensor within L mm after the

leading part of the paper has passed the outlet sensor.

2.52" (64 mm) L 15.77" (400.6 mm)

<

=

<

=

Paper size error

• The trailing part of the paper does not pass the paper sensor within L mm after the

leading part of the paper has passed the paper sensor.

2.52" (64 mm) L 15.77" (400.6 mm)

<

=

<

=

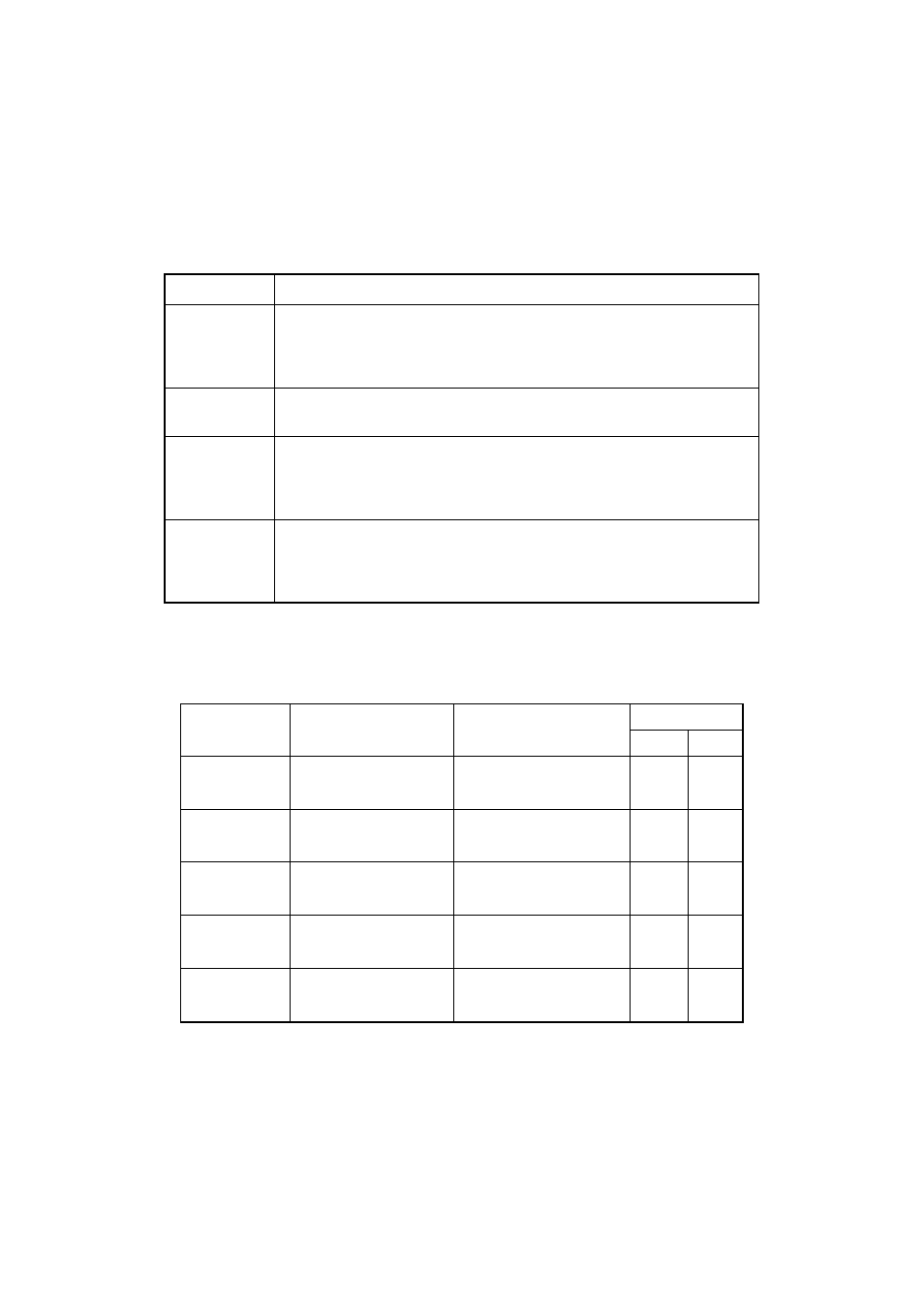

Type of Error

Paper feed error

Paper feed jam1

Paper size error

Paper outlet jam

Paper feed jam 2

Supervisory Sensor

Electromagnetic clutch ON/

Paper sensor ON

Paper sensor ON/

Outlet sensor ON

Paper sensor ON/

Paper sensor OFF

Outlet sensor ON/

Outlet sensor OFF

Paper end sensor OFF/

Outlet sensor OFF

Reference Value

69.8

122.9

2.52" (64 mm) L

15.77" (400.56 mm)

121.9

Pluse

Minus

—

—

—

45.0

20.0

35

20.0

—

45.0

20.0

Error

Unit: mm

<

=

<

=

2.52" (64 mm) L

15.77" (400.56 mm)

<

=

<

=