Water connections, Controls, Water pressure switch – Raypak RAYTHERM P-926 User Manual

Page 10: Automatic chlorinators and chemical feeders, Automatic chlorinators and chemical, Feeders, Flow switch

the time clock may be used for this purpose with

instructions not to override this sequence manually.

See wiring diagram section for electrical hookup loca-

tion of the fireman switch in the electrical circuit.

CONTROLS

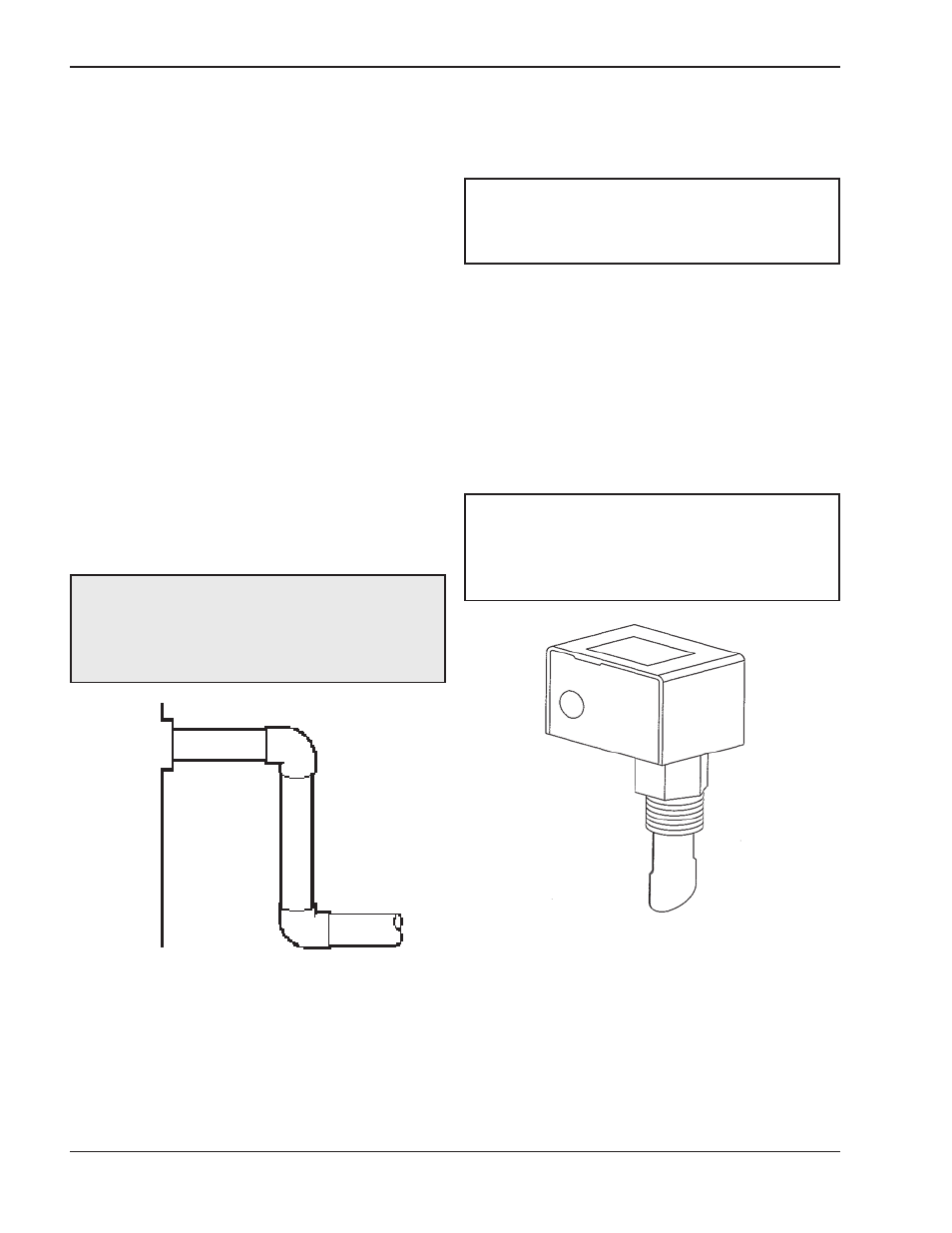

Flow Switch

This dual purpose control shuts off the boiler in the

case of a pump failure or low water condition. It is

mounted and wired in series to the main gas valve.

Standard on all models.

10

Water Connections

Location

The heater requires water flow and positive pressure

to fire and operate properly. It must therefore be

installed downstream of the discharge side of the filter

pump. A typical installation is plumbed as follows:

1. The inlet side of the filter is plumbed directly to the

discharge side of the filter pump;

2. The outlet side of the filter is then plumbed to the

inlet of the heater; and

3. The outlet of the heater is plumbed to the return

line to the pool or spa. The pump, filter and heater

are thus plumbed in series.

Heater must be located so that any water leaks will not

damage the structure of adjacent area. High tempera-

ture plastic pipe (CPVC) may be connected directly

into the heater Models 926-1223, if local codes permit

and if controls operate the pump for at least fifteen

minutes after the heater is turned off.

When local codes permit the use of less than four feet

high temperature piping or two elbows, provisions

should be made to always shut the heater off a mini-

mum of 15 minutes prior to pump shut down in order

to carry away residual heat and prevent damage to the

low temperature piping. A fireman switch included in

CAUTION (Models 926-1223): NEVER install PVC

directly into heater. Four feet of copper or high

temperature pipe and two elbows are required

between the heater and the PVC connections. See

Fig. 8 below.

Fig. 8: Plumbing

NOTE: (Models 926-1223): If piping is used into the

heater, this piping (copper) must be anchored or

screwed into the flange (metal) if operating

pressures above 30 PSI are encountered.

NOTE: Flow switch will not operate if flow is less

than:

Models 926-1223

60 gpm

Models 1287-1826

85 gpm

Models 2100-4001

180 gpm

Fig. 9: Flow Switch