Installation, Gas connection, Gas pipe pressure testing – Regency FIREGENIE FG39-NG User Manual

Page 16: Aeration adjustment

16

Regency FG39 FireGenie Freestanding Gas Stove

INSTALLATION

GAS CONNECTION

The gas line should be rigid pipe. Copper may

also be used if approved by AS5601-2004.

The gas connection at the valve is 1/2 male. For

minimum and maximum supply pressure see the

System Data Table.

GAS PIPE PRESSURE

TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.45

kPa). Disconnect piping from valve at pres-

sures over 3.45 kPa (14" w.c.).

The manifold pressure is controlled by a regu-

lator built into the gas control, and should be

checked at the pressure test point.

Note: To properly check gas pressure,

both inlet and manifold pressures

should be checked using the valve

pressure ports on the valve.

1) Make sure the valve is in the "OFF" position.

2) Loosen the "IN" (# 3) and/or "OUT" (# 4)

pressure tap(s), turning counterclockwise

with a 1/8" (3mm) wide flat screwdriver.

3) Attach manometer to "IN" and/or "OUT"

pressure tap(s) using a 5/16" (8mm) ID

hose.

4) Seal and or check the pilot outlet (# 8)

5) The pressure check should be carried out

with the unit burning and the setting should

be within the limits specified on the safety

label.

6) When finished reading manometer, turn off

the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8"

(3mm) flat screwdriver. Screw should be

snug, but do not over tighten.

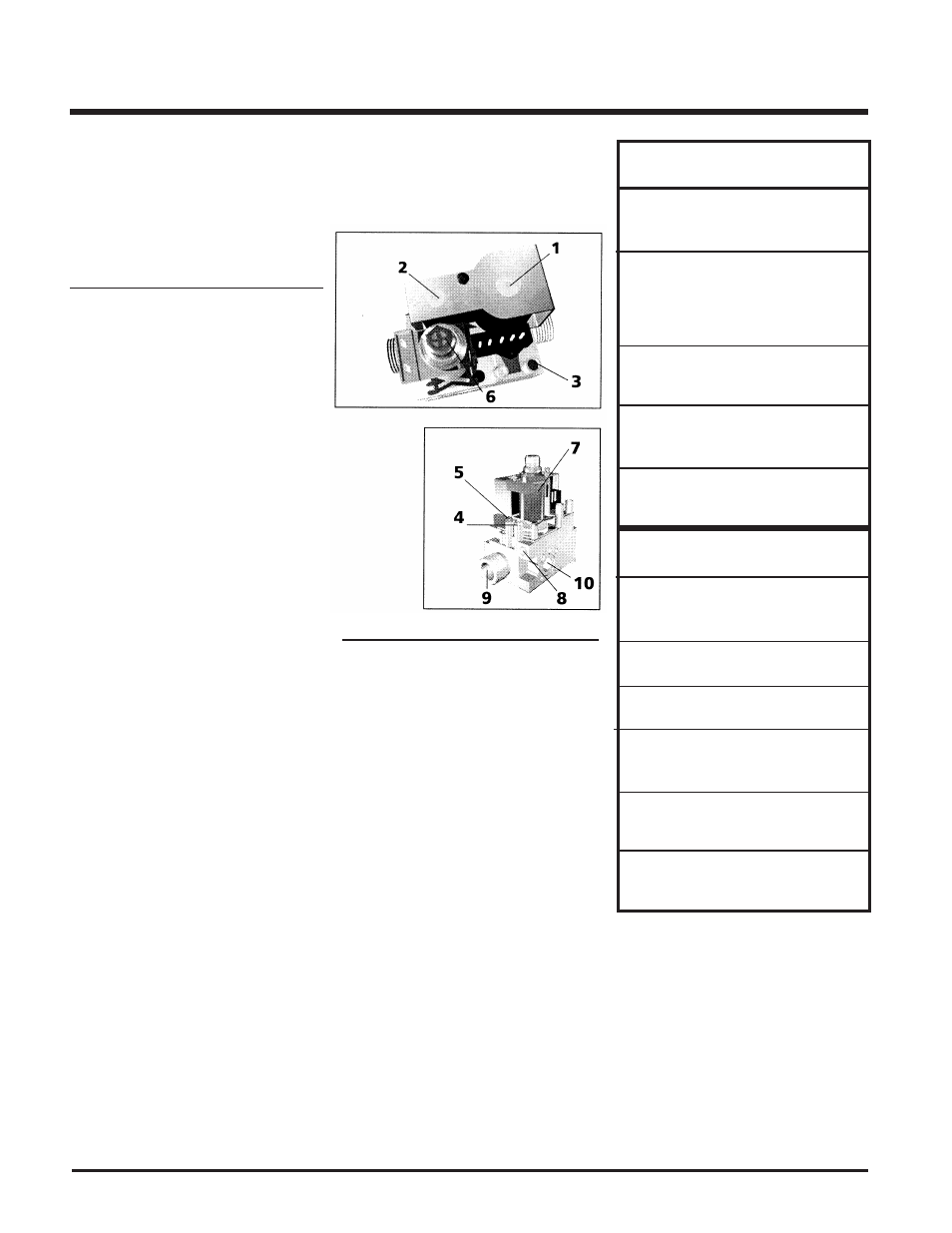

S.I.T. Valve Description

1) On-Off Solenoid Valve EV1

2) On-Off Solenoid Valve EV2

3) Inlet Pressure Test Point

4) Outlet Pressure Test Point

5) Connection for Pressure Regulator/Com-

bustion Chamber Compensation

6) Pressure Regulator for Minimum and Max-

imum Outlet Pressure

AERATION

ADJUSTMENT

The burner aeration is factory set but may need

adjusting due to either the local gas supply or

altitude.

FG39 with 40 mj.

FG39-NG

Fully Open

FG39-LPG

Fully Open

FG39 with 31 mj.

FG39-NG

6 mm Open

FG39-LPG

10 mm Open

Caution: Carbon will be produced if the air

shutter is closed too much.

Note: Any damage due to carboning re-

sulting from improperly setting the

aeration controls is NOT covered

under warranty.

Burner Inlet Orifice Sizes:

NG

LPG

Burner

#32

#50

2.95mm 1.78mm

Max. Input NG

40 Mj/h

LPG

38 Mj/h

Min. Input NG

20 Mj/h

LPG

19 Mj/h

Supply Pressure

NG

min. 1.13 kPa

LPG

min. 2.75 kPa

Manifold Pressure

NG

.94 kPa

LPG

2.55kPa

Electrical: 240 V. 1.13A 60Hz.

Circulation: 2 speed fan, 125/75 CFM.

Log Set: Ceramic fiber, 7 per set.

System Data

FG39 Converted to 31mj.

Burner Inlet Orifice Sizes:

NG

#37 2.65mm

LPG

#52 1.6mm

Max. Input - NG/LPG

31 Mj/h

Min. Input - NG/LPG

16 Mj/h

Supply Pressure

NG

min. 1.13 kPa

LPG

min. 2.75 kPa

Manifold Pressure

NG

.89 kPa

LPG

2.55kPa

Electrical: 240 V. 1.13A 60Hz.

Circulation: Variable speed fan, 125/75 CFM.

Log Set: Ceramic fiber, 7 per set.

System Data

FG39 with 40mj.

7) Gas Outlet Pressure Electric Modulator

8) Pilot Outlet

9) Main Gas Outlet

10) Side Outlet