Burner tray removal, Gas valve removal, Main burner and orifice remova – Raypak 1334001 User Manual

Page 45: High limit or tankstat removal, Heat exchanger removal, Main burner and orifice removal, Service and maintenance procedures, Troubleshooting—pumps, Tube cleaning

45

Troubleshooting—Pumps

Failure To Pump

1. Pump not properly primed.

2. Wrong direction of rotation.

3. Speed too low.

4. Total head too high.

Reduced Capacity and/or Head

1. Air pockets or leaks in suction line.

2. Clogged impeller.

3. Foot valve strainer too small or clogged.

4. Excessive suction lift (over 15 feet).

5. Insufficient positive suction head (for hot water).

6. Total head more than that for which pump is

intended.

7. Excessively worn impeller and wearing rings.

Rapid Wear of Coupling

1. Misalignment or a bent shaft.

2. Sagging motor mounts (over-oiling).

Pump Loses Prime

1. Air leaks in suction line.

2. Excess air in water.

3. Water seal in stuffing box not functioning.

4. Excessive suction lift and pump operating too near

shut-off point.

Overloaded Driving Unit

1. Head much lower than that for which pump is

designed.

2. Speed too high or higher than that contemplated.

Mechanical Troubles and Noise

1. Misalignment.

2. Excessive suction lift or vapor binding (hot water).

3. Bent shaft and/or damaged bearings.

4. Suction and discharge piping not properly support-

ed and anchored.

SERVICE AND

MAINTENANCE

PROCEDURES

Tube Cleaning

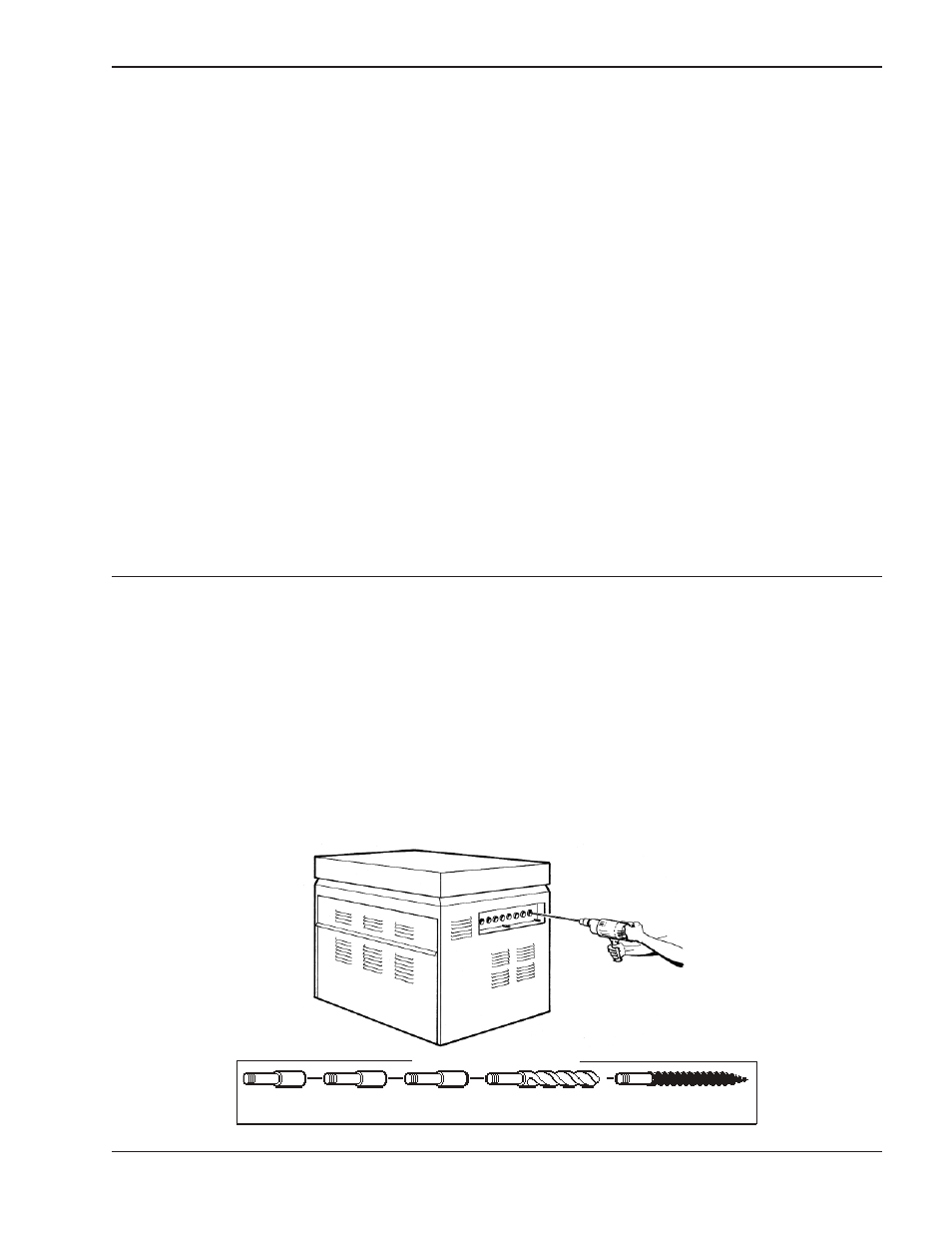

Establish a regular inspection schedule, the frequency

depending on the local water condition and severity of

service. Do not let the tubes clog up solidly. Clean out

deposits over 1/16" in thickness.

The heater may be cleaned from the side opposite the

water connections as shown, without breaking pipe

connections. It is preferable, however, to remove both

headers for better visibility through the tubes and to be

sure the residue does not get into the system. Note

that you do not remove the top pan or the heat

exchanger generally. After reaming with the auger,

mount the wire brush and clean out the debris remain-

ing in the tubes. Another method is to remove the heat

exchanger, ream tubes and immerse heat exchanger

in noninhibited de-scale solvent.

RAYPAK TUBE CLEANING KIT

Extension Pieces (5)

Auger with Carbide Tip

Wire Brush

P/N 052871F - 5/8 DIA.

P/N 052870F - 7/8 DIA.

Fig. 37: Raypak Tube Cleaning Procedure