Gas pressure regulator, Venting of diaphragm gas components – Raypak 1334001 User Manual

Page 21

21

Gas Pressure Regulator

The gas pressure regulator located in the gas valve is

preset nominally at 4" WC for natural gas, and 11" WC

for propane. Between the gas valve and the burners is

a 1/8" pipe plug. The pressure at this point, taken with

a manometer, should be about 3.7" WC natural gas

and 10.5" WC propane. Models 0181, 0261, 0331, and

0401 should be 3.9 WC natural gas. If an adjustment

is needed, turn adjustment screw clockwise to

increase pressure, or counter-clockwise to decrease

pressure.

Venting of Diaphragm Gas

Components

Gas train components that have diaphragms in their

construction are supplied with a bleed line connection

that must be connected to the outside atmosphere as

required by the National Fuel Gas Code. Under NO

circumstances shall bleed lines terminate in the gas

utilization equipment flue or exhaust system.

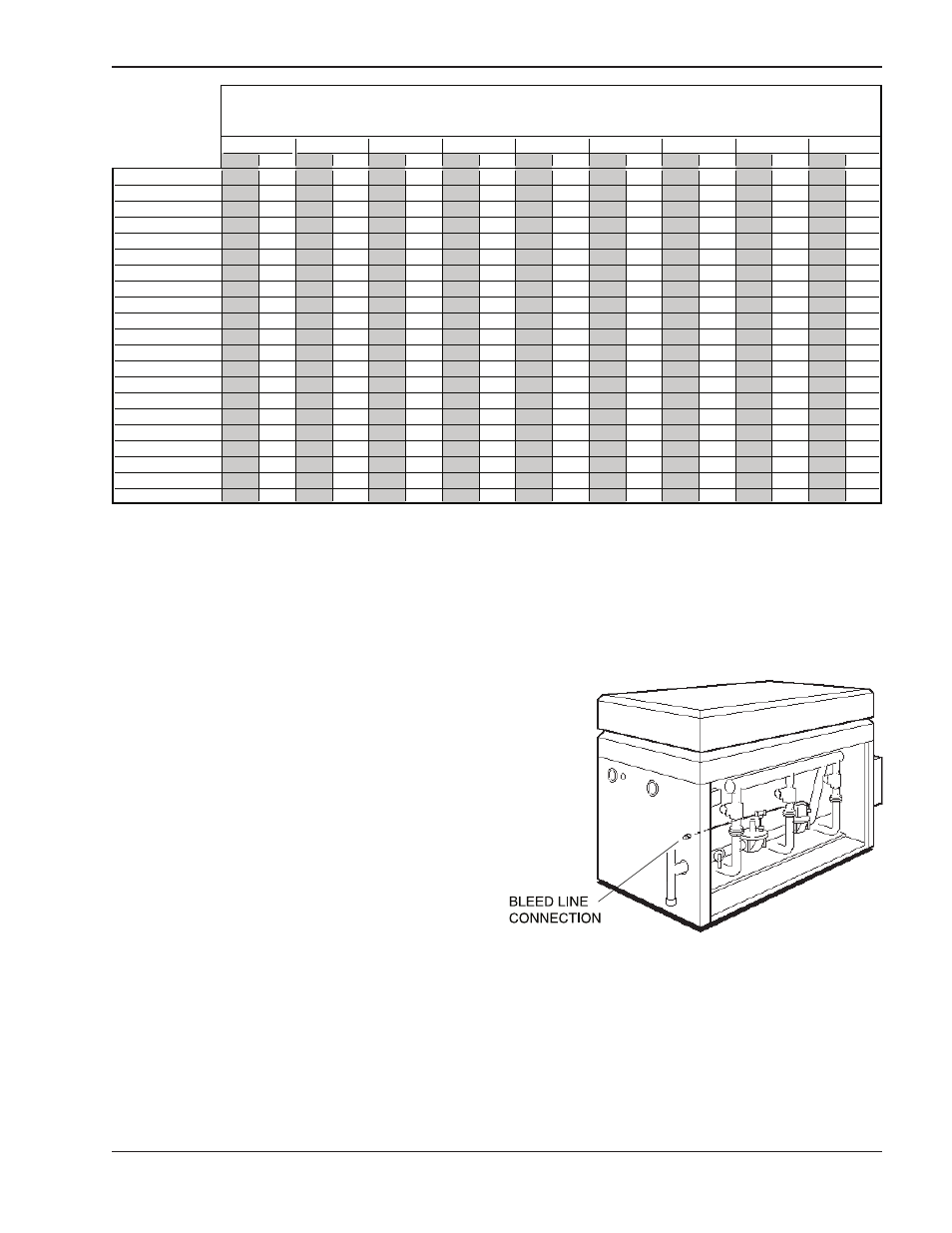

Fig. 20: Bleed Line Connection

N

P

N

P

N

P

N

P

N

P

N

P

N

P

N

P

N

P

0133

15

35

60

145

200

500

*0182/0181

-

15

30

65

95

250

400

-

-

-

-

-

-

-

-

-

-

-

*0260/0261

-

10

20

40

60

140

250

560

-

-

-

-

-

-

-

-

-

*0330/0331

-

15

25

35

85

150

380

360

-

-

-

-

-

-

-

-

-

*0400/0401

-

-

15

25

60

100

260

250

-

-

-

-

-

-

-

-

-

0

0

5

0

6

3

0

3

1

0

5

1

5

6

5

3

5

1

0

1

-

4

1

5

0

-

-

-

-

-

-

-

0

4

3

0

5

2

5

9

0

0

1

5

4

5

2

0

1

-

-

4

2

6

0

-

-

-

-

-

-

-

0

0

6

0

6

2

0

8

1

5

7

0

8

5

3

0

2

-

-

-

4

2

7

0

-

-

-

-

-

-

0

0

5

0

8

4

5

8

1

0

3

1

5

5

0

6

5

2

5

1

-

-

-

4

2

8

0

-

-

-

-

-

0926/0962

-

-

-

15

20

45

45

110

150

360

400

-

-

-

-

-

1083/1125

-

-

-

10

15

35

35

80

120

300

300

-

-

-

-

-

1178/1223

-

-

-

-

-

25

25

60

85

220

200

-

-

-

-

-

1287/1336

-

-

-

-

-

25

20

55

75

180

170

325

560

-

-

-

1414/1468

-

-

-

-

-

20

15

45

65

150

165

300

500

-

-

-

1571/1631

-

-

-

-

-

15

15

35

50

120

125

250

400

-

-

-

1758/1826

-

-

-

-

-

15

10

30

40

100

100

225

340

-

-

-

2100

-

-

-

-

-

10

10

25

30

80

75

175

260

-

-

-

2500

-

-

-

-

-

-

-

15

20

55

55

135

160

400

600

-

3001

-

-

-

-

-

-

-

10

15

35

40

85

120

250

500

-

3500

-

-

-

-

-

-

-

-

10

30

30

45

80

200

400

600

4001

-

-

-

-

-

-

-

-

5

20

25

35

65

160

300

400

1-1/2"

3/4"

MAXIMUM EQUIVALENT PIPE LENGTH

NATURAL GAS 1000 BTU/Cubic Foot .60 SPECIFIC GRAVITY @ 0.5" W.C. PRESSURE DROP

2"

2-1/2"

3"

4"

PROPANE GAS 2500 BTU/Cubic Foot 1.53 SPECIFIC GRAVITY @ 0.6" W.C. PRESSURE DROP

"

4

/

1

-

1

"

1

"

2

/

1

* Models 0181, 0261, 0331, and 0401 are Low NOx units and are not available in propane.

A minimum of 7" WC and a maximum of 10.5" WC upstream pressure under load, and no load conditions must be provided for natural gas

or a minimum of 11" WC and a maximum of 13" for propane.

Pressure drops from the no load condition to the full load condition must be no more than 30% for proper operation.

Table G: Maximum Equivalent Pipe Lengths