Roberts Gorden Combat Cabinet Heaters POP-ECA/PGP-ECA 015 to 0100 User Manual

Page 54

COMBAT

®

C

ABINET

H

EATERS

I

NSTALLATION

, C

OMMISSIONING

, O

PERATION

AND

S

ERVICE

M

ANUAL

48

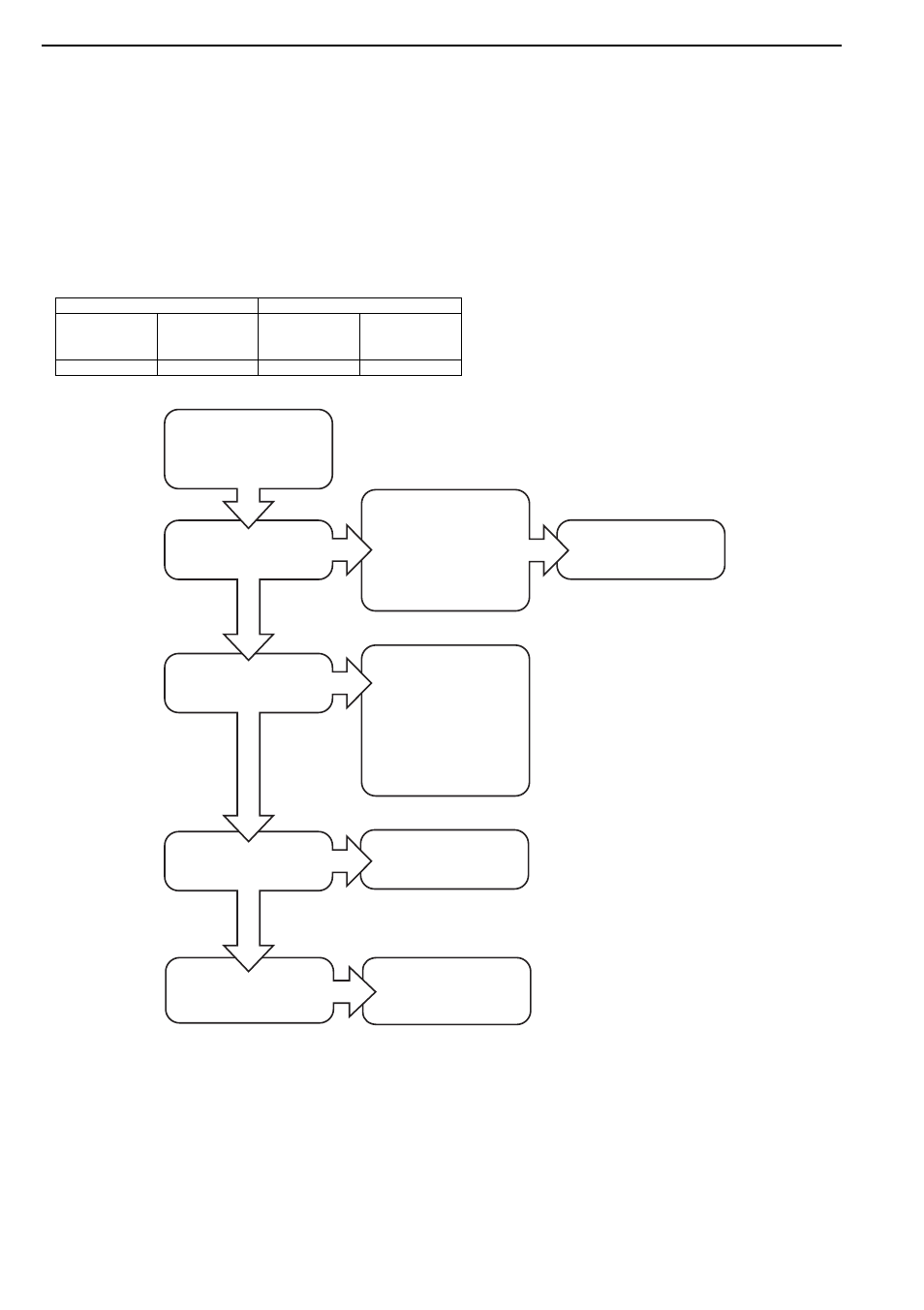

14.4 Troubleshooting for Flame Supervision System

Heater Operating

TROUBLESHOOT ENDS.

If problems persist, contact

ROBERTS GORDON

®

at

Tel: +44 (0)121 506 7709

www.rg-inc.com

No

Control box faulty.

Replace with correct type.

Yes

'Lockout' still occurs?

No

OIL-FIRED

Clean or replace photo

electric cell as necessary.

GAS-FIRED

Replace flame probe.

Check for it's correct position.

Check wiring to flame probe.

Check burner earth

connection.

Yes

Does 'lockout' occur when

a flame is present?

Repair or replace.

OIL-FIRED

Is there a stray light entering

the burner or is there a

flame?

GAS-FIRED

Inspect and test the flame

probe and wiring for a short

circuit to earth.

Yes

START

Connect a DC ammeter in

series with the flame monitor.

Turn on all controls and

ensure supply to burner

No

No

Is there a current flowing

in excess of the max.

value for NO flame?

The flame supervision system is different for gas-fired and oil-fired heaters but may be tested in a

similar way.

Gas-fired heaters use a rectification flame probe to monitor the flame.

Oil-fired heaters use a photo sensitive cell to monitor the flame.

To connect a suitable meter into the circuit to monitor the flame signal current, disconnect one of the

wires to the monitor (there is only one for gas-fired).

Connect a suitable DC ammeter between the terminal just disconnected and the wire taken from it.

Should the meter read backwards, then reverse its connections.

Readings should be approximately as follows(For further details see burner manufacturer’s

instructions):

Oil-Fired

Gas-Fired

Maximum flame

current with no

flame

Minimum flame

current with

flame

Maximum flame

current with no

flame

Minimum flame

current with

flame

12 μ Amp

25 μ Amp

0.5 μ Amp

1.0 μ Amp